If you use a handheld, pinless moisture meter to keep tabs on the moisture content of your lumber, you know how valuable that information can be — whether you’re building fine furniture, drying green lumber or installing wood flooring for a living. The ability to instantly read moisture content and evaluate wood’s suitability for use saves money and averts frustration, because you know when it’s dry enough for your application. Without a moisture meter, a guess is all you really have.

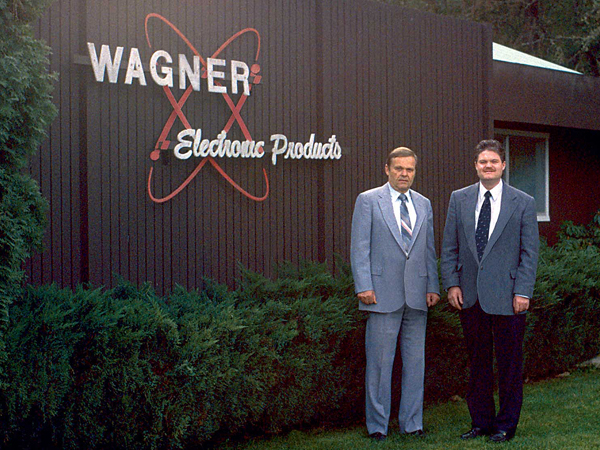

For this convenience, we can tip our hats to three generations of the Wagner family who have helped make it possible: Delmer, who founded Wagner Meters in 1965, his son Ed, who’s been its president and CEO for nearly three decades, and now Delmer’s grandson Eric, who manages the company’s marketing and social media channels. This year, the Wagner family and its employees have celebrated a half century of serving the woodworking, wood products and wood flooring industries with metering tools.

To mark the occasion, the Rogue River, Oregon-based company held a commemorative giveaway of 50 anniversary T-shirts and one grand prize package tailored to a flooring installer, woodworker, building inspector or sawmill and forest products professional. The award included an application-specific Wagner meter and accessories for it, a Wagner thermo-hygrometer and a special 5-lb. commemorative chocolate bar in a 50th anniversary wrapper.

“It’s hard to believe that (our company) has been in business for 50 years! And we’re still going strong, thanks to our many loyal customers engaged in woodworking,” Eric says.

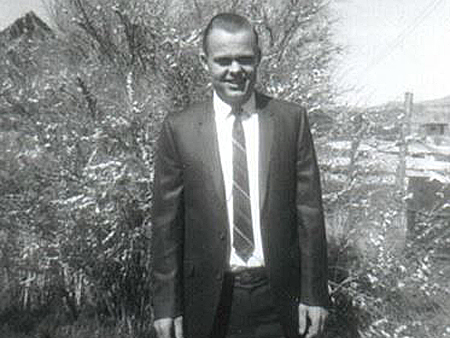

But woodworkers actually weren’t Wagner’s first customers back in the mid-‘60s. At that time, Delmer — a former electrician for a Redmond sawmill — saw an opportunity to innovate the moisture detection equipment being used within the forest products industry. The contact moisture detectors of the time “were in a cabinet the size of a man and came equipped with radio vacuum tubes. They were hard to use, hard to calibrate and hard to interpret,” Eric recalls.

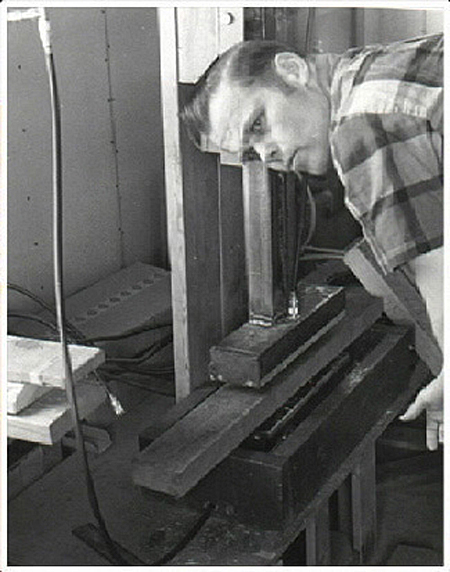

Hearing management’s frustration with the limitations of that early technology, Delmer started experimenting to find a better solution. Working out of his garage, he developed the first in-line moisture meter that used transistors rather than vacuum tubes. It was much smaller, more economical and easier to calibrate. The mill patented Delmer’s first design, and its success prompted him to continue innovating in the field of metering technology. Eventually, he formed his own moisture meter company: Wagner Electronics.

An evolution of that first Wagner transistorized moisture meter soon followed. It was smaller and improved in other ways. Delmer began marketing it to the sawmill industry at-large with an unbeatable warranty, Eric says. “Grandpa allowed them to use his detector for a month at no cost or obligation. They were to call him if they had a problem with it. Otherwise, he would return in 30 days to either pick it up or collect payment.”

The new meters were eagerly adopted by other lumber mills, and Wagner Electronics was off to a quick start.

“My grandfather’s vision and creative thinking led to our company’s success in those early years,” Eric says. “He seemed blessed with an amazing intuition that led him to create a slew of new and innovative products that greatly improved the way moisture is measured.”

Among them came the first non-contact moisture meter. It offered improved longevity over other options, since the sensor never touched the wood or suffered the resulting wear and tear. Delmer also pioneered an in-kiln moisture meter to help mills get the maximum value from their inventory. It enabled kiln operators to better evaluate the process of drying lumber, so wood would come out of the kiln neither too wet nor too dry. It reduced the cost and time lost to re-drying wood and prevented defects like cracking or warping from occurring, due to over-drying.

“That whole process of kiln troubleshooting with moisture meters … saved the mills hundreds of thousands of dollars,” Eric adds.

In 1967, Delmer’s son Ed began working for the company at just 10 years old, wiring, soldering and testing meters. Ed continued to learn the family trade through college, grounding his knowledge in all technical aspects of the business. He earned a degree in engineering and then became Wagner’s production manager. In 1987, when Delmer retired, Ed took the reins as majority stockholder and became Wagner Meter’s new president and CEO. He continues that tenure today.

“Dad is cut from the same cloth as his father when it comes to creating innovative products,” Eric says.

The capstone of Ed’s inventions was the handheld moisture meter. Developed in the early ‘80s but not marketed aggressively, Eric says his father’s design became a major growth opportunity for Wagner during the recession in the early ‘90s. It was a more economical alternative for lumber mills than the larger moisture metering equipment they could no longer afford.

Even through tough economic times, the lumber mills knew Wagner was still making their needs a priority. “Despite the recession, we had a meter that our customers needed and could afford. So we survived,” Eric says.

And, handheld meters offered Wagner another emerging customer base, too: hobbyist and professional woodworkers. A couple of decades ago, the only handheld moisture meter option available was the pin-style meter. A pair of sharp probes on these meters leave prick marks in the wood, and the technology offers only limited accuracy. Wagner developed and began to market a pinless option, which uses a sensor plate rather than pins to take deeper readings of moisture levels but without damaging the wood. At first, woodworkers were skeptical about the new design’s accuracy, but apprehension was dissolved by third-party testing, Eric says. Then, Wagner pinless meters were embraced by the woodworking community. “Tests showed our meters were not only more accurate than the best brands of pin meters, but (also) a lot easier to use,” he adds.

Many evolutions of pinless moisture meters have followed over the years, and today, Wagner offers the MMC220–its most popular model for woodworkers. Aside from taking fast, accurate moisture readings on dry wood surfaces, the MMC220 can also detect internal moisture content when wood surfaces are wet. “We can measure right through moisture, unlike other meters on the market. Their readings are skewed much higher if even a trace of humidity or condensation is on the wood’s surface,” Eric says.

Designed, tested and assembled in the U.S., the MMC220 can evaluate moisture levels in all wood species, from exotics to domestics. It sells for $395, and the company backs it with a 7-year warranty. “We feel it’s priced competitively in light of its proven accuracy, various features and overall high reliability and quality,” he adds.

But reliable, economical moisture meters are just part of Wagner’s commitment to woodworkers and its other wood products and wood flooring customer bases. Hand-in-hand with hardware, Eric says, is Wagner’s focus on education.

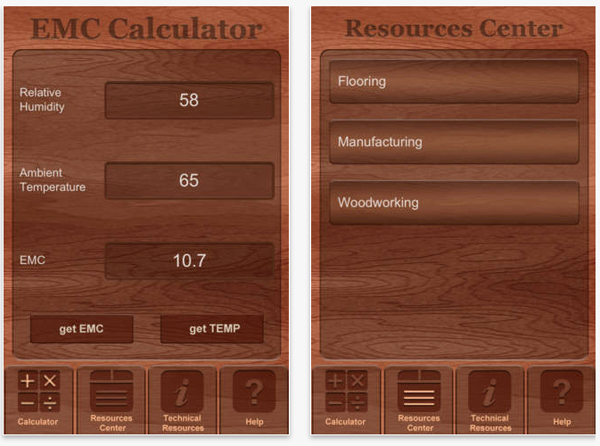

“We accomplish this using a variety of means … articles for trade journals, newsletters and our website, producing free instructional videos, interacting with our customers through the Internet and our customer service representatives, and using social media … We’re currently making products that take advantage of the Internet, tablets, (smartphones) and apps, making it easier and more convenient to transfer, access and store data.”

Eric also recommends the company’s free WoodH2O app, which offers a variety of tools and resources for woodworkers. It’s available for both Android-based and iPhones. To download it, click here.

And, he says the company’s commitment to staying abreast of the latest technology will continue, as Wagner Meters plots its course for the next 50 years.

“Now, with everyone carrying a computer around in their pocket that is more sophisticated than what NASA originally used to get to the moon, it has given us even greater opportunities to develop still more useful and innovative devices … Wagner Meters will always be in the forefront, taking advantage of these advances by innovating, developing newer, more sophisticated products and reaching out to our customers in perhaps unheard-of ways,” Eric says.

Reflecting over a half century of Wagner’s family-owned, family-run business, Eric believes there are many reasons for the company’s success. Family values have always been at the core of its mission. Sustaining a culture of innovation and manufacturing reliable, quality products is also key. He credits the dedication, creativity and work ethic of Wagner’s employees, some of whom have worked for the company for between 20 and 30 years. But none of this would matter without the company’s commitment to serving customers and understanding their needs.

“On behalf of my grandpa (now retired), my father and the best employees anywhere, I want to thank our woodworking customers for their unwavering loyalty and trust in Wagner Meters over these many years. We greatly appreciate you and pledge to continue providing you with superior service and innovative products for our next 50 years, and beyond.”

Learn more about Wagner Meters by clicking here.