Considering all the options available for a standard 10″ 1-1/2HP Delta Contractor’s Saw – fences, miter gauges, sliding tables, router tables, etc. – can you put a bigger motor on one, or is it at its practical limit?

Michael Dresdner: One and a half horsepower is about as large a motor as can run on a standard 110 house outlet (typically 15 amps.) Go much larger and you are into larger wiring and breakers, which means a separate line from the breaker box, or more commonly, a switch to a 220 motor, which uses two hot leads and a ground instead of one hot and one neutral. In short, consider your electrical situation first. Larger motors are always nice, but once again, it only makes sense if you will need the extra power. You won’t need it for cutting sheets of 3/4″ plywood, but if you plan to cut thick slabs of dense wood, it could be handy.

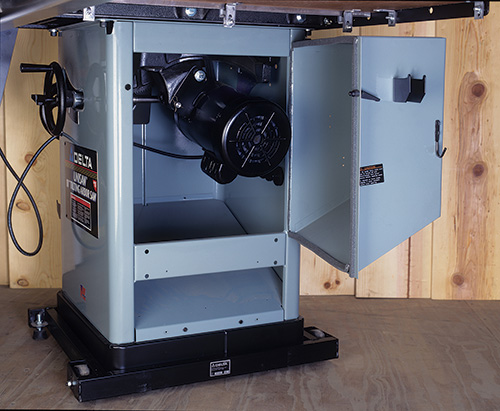

Rob Johnstone: The 1-1/2HP is the practical limit in my opinion. For one reason, you only have a single belt drive to transfer the power to the arbor assembly. With cabinet-quality saws, for example … that have larger motors … there are often three belts to effectively transfer the energy. Also, the increased weight of the larger motor hanging off the back of the contractor’s saw will increase the torsion on the trunnion and arbor assembly, exacerbating the likelihood of racking the saw blade out of alignment if you try to tilt the blade and cut a miter.

Simon Watts: It’s unwise to tamper with the power of a motor. The unit–bearings, gears, etc., have been designed for the rated horsepower.