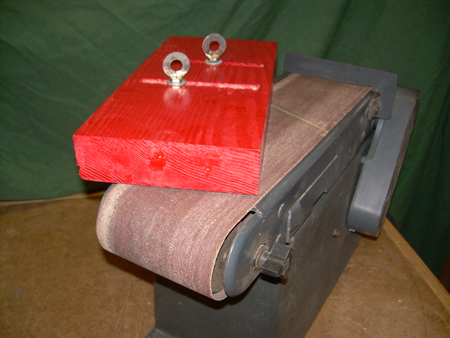

I build a lot of small boxes in my shop but when sanding the edges of small boards on my horizontal sander, but I was having trouble keeping the edges from getting rounded over by not being able to hold the board vertical to the belt. So here is the solution I came up with. I cut a piece of 1-1/4 x 1-1/4 angle iron 4 inches long. I drilled two sets of holes in each side of it approximately 1-inch from each end. I then bolted it to the side of my horizontal sander.

Then, I took a two by six board twelve inches long and cut two 3/8-inch slots across it to within 1/2-inch of each edge spaced apart so as to match the holes in the angle iron. Then I placed two large washers between the board and the angle iron so as to space the board above the sanding belt. Using 1/4-inch bolts with washers welded to the tops for tightening, I bolted the board down and tried out my new guide. By using 3/8-slots and 1/4-inch bolts, I can cant the guide across the belt, using the entire width of the belt instead of just one spot on the belt all of the time. It sure works for me, and now I can get square edges every time.

-Oneil Long