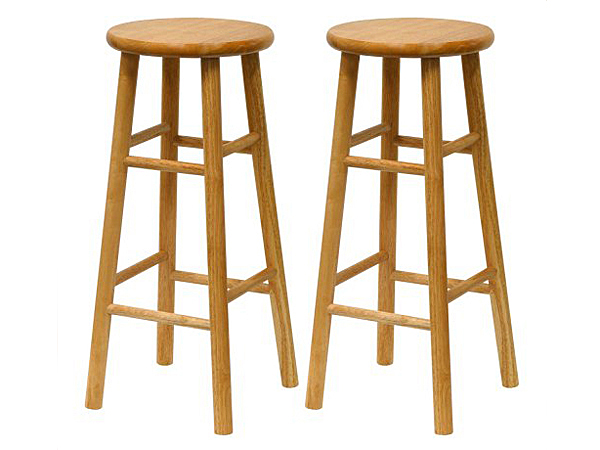

I have a set of very nice bar stools that have moved with me to my new house. This new place has a bar that is much lower (about 4 inches) than the bar in my last house. So I need to shorten the legs of the stools to suit it. I know that shortening all four legs is critical because three points define a plane and, if one leg is not in plane, I’ll have a rocking horse. I read somewhere, a long time ago, of a technique that improves my chances of getting all four leg bottoms in the same plane, but I don’t recall now what the method was.

Rob Johnstone: You are correct that the task is ripe with the possibility that you will not get all four legs exactly the same length. But with that said, don’t let the challenge get the best of you. Just mark the lengths carefully, measuring from the same point on the stool (be it from the bottom or the top of the legs) and carefully make the cuts. If it goes well, everything is Jake. If not, place the stool on a dead flat surface (like a cast-iron table saw top) and find out which leg is the offender. You can almost always make it right by adjusting just one of the legs. I do this with a sander … I just take my time and sand off the longest one a bit at a time until it sits properly.

Tim Inman: There is an underlying assumption here coupled with a reality that makes everything else irrelevant. This is where principles and practices collide. You are correct in your definition of a plane. Any three points will define the plane’s surface. If all four legs of the chair are not exactly the same length, then only two or three of them will contact the plane at any one time. If you are super accurate in your workmanship and use a perfectly flat surface plate to gauge and test your work, you might be able to get all four legs the same length so they will touch the surface plate’s plane at the same time.

BUT, floors are almost never flat! So even if you do get the “perfect” job of joinery accomplished, the chair will still probably be tippy when it is in service on site. The floors are not flat. Then, even if the floor is flat, the seat board on the chair may warp over time pulling the leg length out of spec. If the chair is sitting on a carpeted floor, the compression factor will allow the chair to seem like it is sitting with equal weight on each leg — but it isn’t.

Why does grandma’s old squeaky chair sit flat on all fours? Because the joints are loose and they move to accommodate pressure on the joints. I’ve repaired hundreds and hundreds of chairs over the years (maybe thousands!). I’ve been through this discussion so many times. After my rock-solid repaired chair goes home, it is “tippy.” Customer brings chair back and sets it on my perfectly flat ground cast-iron proofing table (my table saw). Chair is perfect. We explain why the chair is tippy at home. We show the customer the chair can be tippy on my concrete shop floor, too. Customer is okay with the work and the repair, but wishes the old chair could still be repaired and somehow still “fit” the floors like it did before. You can’t have it both ways.

Work to 1/32-in. tolerances, get the joints solid and tight, and then go fishing. You’re as close as you’re going to need to be — and anything more just gives headaches and makes the chair unnecessarily shorter — again and again.