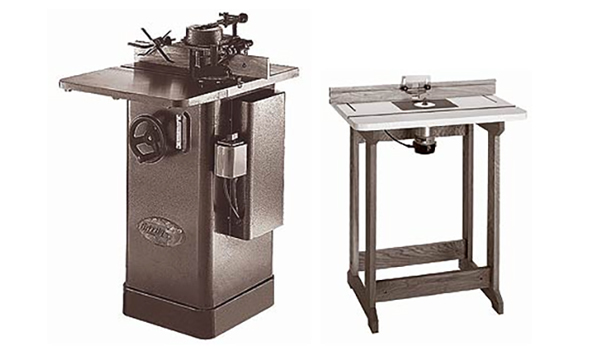

I’m a novice fine woodworker (but longtime framing carpenter) about to delve into cabinet making. I plan to make a significant number of cabinets for a kitchen, bathrooms and built-ins for a recent addition to my house. I first assumed l wood need a heavy-duty 3 hp router and a nice table to turn a panel-raising bit (horizontal), but then found several small shapers in the 1 to 1-1/2 hp range priced about the same. Are these small shapers suitable for panel raising? They seem underpowered compared to the router power recommendations – but perhaps the knife configuration makes up for this? Does the flexibility of the router outweigh any advantages to the shaper? And, since the initial cost is similar, does buying an assortment of shaper cutters differ in price from a similar assortment of router bits?

Michael Dresdner: You’ve asked a lot of good questions, but missed one big one, which has to do with speed.

Routers typically run at 22,000 to 25,000 rpm. Shapers typically spin in the 7,000 to 10,000 range. With large cutters, slower speeds and higher torque are just the ticket. (Remember, it is the tip speed that matters, not the rpm. Larger cutters have a larger tip travel circumference, and hence a higher tip speed.)

But to answer your questions: Yes, small shapers are suitable for panel raising, and yes, in some ways a heavy-duty router is more versatile or flexible, and yes, shaper cutters cost more (and are harder to find) than the ubiquitous router cutters.

Lee Grindinger: A router is more versatile than a shaper, and the shapers you’re looking at are not going to perform well. A shaper is a valuable production tool but not really needed for the small number of panels you have in mind. Since it is a choice between a powerful router and a tiny shaper it’s an easy one: go for the router. Router bits are generally cheaper and more varied. If you decide to take your enterprise to the next level and manufacture cabinets as a livelihood, a shaper would be a worthwhile purchase.