Maybe it’s a cliché, but sometimes the stereotype fits: we don’t always read our manuals when assembling machinery. Well, I’ll speak for myself here anyway, at times, but I’ll bet I’m not the only woodworker out there who’s nodding yes at this admission. Sometimes the small print and poorly photographed images in tool manuals are just obstacles that seem to stand in the way of getting a new machine up and running.

If you agree, you’ll appreciate a new social media effort RIKON Tools is undertaking to make the process of assembling a machine easier. With its new 10-326 14-in. Deluxe Bandsaw ($999.99), RIKON not only supplies a printed manual for the tool but also a QR code that links you to a video to show you how the saw goes together (to view it, click here). If you don’t want to wade through the printed pages as you’re bolting the parts for the first time, you almost don’t have to.

Speaking to the reasoning for creating machine assembly videos, Rod Burrow, RIKON’s sales manager and product specialist, says video is a natural extension to step-by-step instructions these days. Or at least it can be. And RIKON is setting out to prove it, using today’s YouTube Channel learning medium.

“We wanted to give the consumer another tool as an addendum to the printed manual to help simplify the assembly process. They say a picture is worth a thousand words; we feel a video is worth a lot more.”

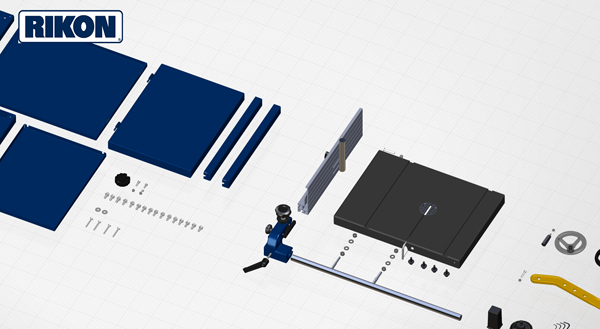

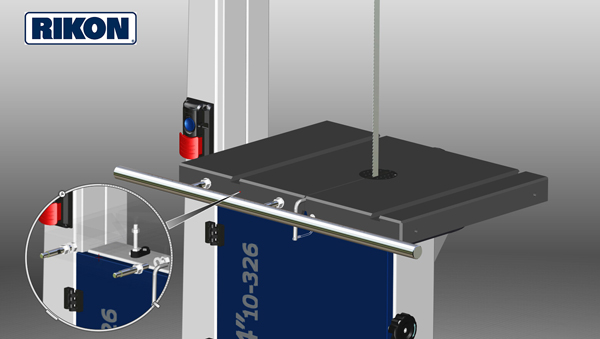

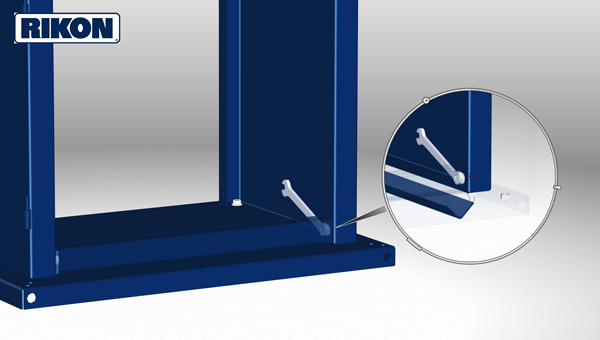

Burrow says work began on the band saw assembly video in January, in order to be ready for the saw’s product launch in March. It’s a graphics-focused animation of the 10-326’s assembly process that lasts just over 4 minutes. Interestingly, there’s no narrative to explain what the viewer is seeing on screen, and you won’t watch a RIKON representative turning screws or setting the machine up, either.

Why the silent film? Burrow says RIKON’s customer base is larger than it once was, and narrating the assembly video could have presented a language barrier for some.

“RIKON has gone global,” Burrow says. “We tried to make the video universal for all to understand. The animation provides a clear visual representation of the product and assembly process.”

To create the video, the company made use of the engineering CAD program that was employed to design the new band saw in the first place. Background music was created and produced by one of RIKON’s product specialists and his friends, Burrow says.

What the new assembly video won’t show you in detail is are various new features that Burrow believes makes the 10-326 stand out from its predecessor — RIKON’s 10-325 Bandsaw. You can see him explain the 10-326 updates in another overview video (click here). For one, the new iteration has spring-loaded, tool-less blade guides to make guide setup quick and easy. It also has a 6-in.-tall quick-adjust rip fence designed to make adjusting for blade drift nearly effortless. Burrow also points out a Quick-Lock Trunnion System. It enables the saw’s cast-iron table to be set and locked with a lever and cam system.

“These improvements, along with a powerful RIKON 1-3/4hp induction motor and 13-in. resaw height, make the 10-326 a top choice in the 14-inch band saw market,” Burrow says.

RIKON also has produced assembly videos for two other new machines that are out now: its 10-324 introductory 14-in. Bandsaw and the 30-217 17-in. Variable Speed Drill Press. Two more videos of other upcoming RIKON machines currently are in development.

Eventually, the company plans to produce similar assembly videos for all new RIKON machines and make them available through a new YouTube Channel. Links to videos will be provided from RIKON’s website. Videos of other sorts are being made as well. You can already watch one that focuses on tracking a band saw blade (click here) and another explaining how to balance and true up grinding wheels.

“Our goal is to create as much online content as possible,” Burrow adds.

If you’re in the market for other power tool machinery besides a new band saw, Burrow says RIKON is bringing many new machines to market this summer. Among them, more surfacing machines with helical cutterheads ranging from 6 to 24 inches. There will be a new 16- x 24-in. 1-1/2hp lathe that runs on 110 volts. And, RIKON has a new 8-in. Wet Sharpener (82-100), 50-300 Oscillating Spindle Sander and an 8-in. Low-speed Long Shaft Buffer (81-808). We’ll have to wait and see what new RIKON videos might be in store for these offerings.

In any event, the option to watch your new RIKON machine “build itself,” in a manner of speaking, through free assembly videos seems timely, when so much of what we are experiencing these days comes by way of online viewing.

“This is another way to provide more information to our customers,” Burrow says. “We feel efforts like these will help consumers with their pre-sale research which will lead them to choose RIKON products!”

To learn more about RIKON power tools, click here.