When a new consumer band saw model hits the market with “updated” features, those improvements typically involve the frame (it gets stronger or taller for more resawing capacity), the blade guides (they get easier to adjust) or the rip fence. Now and again, a motor will get bigger or its sourcing will switch from somewhere on the Pacific Rim to a stateside company. What doesn’t change, however, is the type of motor being offered or the speed with which it drives the blade through wood or metal. In that regard, nothing really changes: an induction motor operates at one speed and, at most, the band saw provides two cutting speeds — slow for metal or faster for wood. Changing the machine over from wood-cutting mode to metal involves moving a drive belt from one pulley to another. It’s a do-able but slow task.

That’s why, at this past summer’s International Woodworking Fair in Atlanta, it was refreshing to see something truly innovative happening in terms of band saw motor technology. RIKON Power Tools has set its sights on taking things to the next level of performance by introducing DVR motors and controllers to wood-cutting band saws.

“It’s been almost 200 years since the band saw was first produced. In that time, the (motor) technology has barely changed, until now,” says Joe Taylor, RIKON’s director of sales.

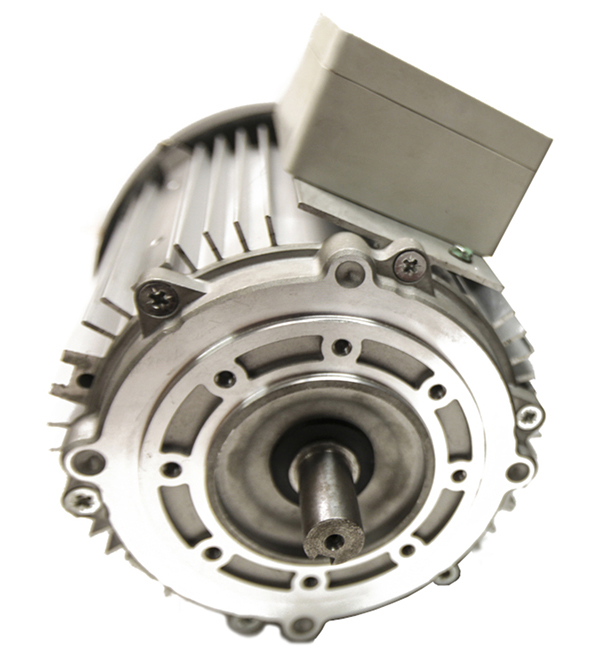

DVR stands for digital variable reluctance. It’s a simpler motor design than the universal or induction motors used on most power tools, and it relies on a microcomputer to control the motor’s output rather than just a surge of electricity when the On/Off switch is flipped. RIKON is partnering with Striatech for this technology.

You may know that DVR is being used in a couple of other woodworking applications already. NOVA™ Teknatool® offers wood lathes with DVR motors, and more recently they’ve added a DVR drill press, too. Striatech’s motor and controller system was initially developed as a part of NOVA’s search to find a better solution for their wood lathes.

“With the help of the University of Auckland, they developed a switched reluctance motor with breakthrough features: virtually silent and vibration-free operation, with the capability of achieving high torque at low speeds and offering incredible efficiency,” Taylor says.

A DVR motor’s ability to provide continuous torque seems an obvious advantage to wood lathes or drill presses where material types, cutting demands and cutter sizes change so often, but Taylor points out the benefit to band saws, too. “Traditional AC motors can bog down or stall under heavy loads — resawing, for example. The result is a poor cut with heavy blade lines left in the wood.”

DVR, on the other hand, delivers continuous speed and torque compensation, thanks to its motor control electronics that are constantly monitoring the load being applied to it. When the motor’s torque output and speed remain the same, Taylor says resaw cuts are smoother, regardless of the thickness of the workpiece or the type of wood being sawn. DVR also produces less vibration than induction motors, which also helps to improve cutting smoothness.

Aside from what amounts to almost unstoppable power delivery, DVR is also infinitely controllable. You need to be able to change speeds when switching from a roughing gouge to a skew chisel, or from a 1/4-in. twist bit to a 2-in. Forstner — so variable speed on a wood lathe or drill press is essential. Now, imagine how useful it could be in band saw applications when you want to cut hardwood one day but a piece of angle iron or plastic the next. One or two cutting speeds won’t serve all needs. But, with RIKON’s new DVR system, making those speed changes will be as easy as tapping a button or turning a dial on the controller box.

“It’s the perfect choice for variable speeds, allowing the band saw to cut different materials optimally,” Taylor adds.

RIKON’s controller will enable the DVR motor to operate at between 100 rpm (45 surface feet per minute; SFPM) up to 2,375 rpm (4,400 SFPM). The company is pre-programming the control box with 15 suggested speed settings for wood, metal and plastic. Those include four settings for wood: resawing, bowl blanks, ripping and crosscutting or scrolling/pattern-cutting. Four “metal” presets will cover carbon steel, stainless, titanium or cast iron. There are also four speed settings for cutting softer, nonferrous metals — aluminum, brass, bronze or copper. And when you need to cut plastic, there are presets for acrylic, nylon or high-density polyethylene. The controller also has one custom preset. All of these settings can be adjusted further by turning the variable speed dial up or down as desired.

“The interface is designed with the user in mind. It’s simple to operate with clear menu options, a rotary dial for selection and an easy-to-see digital readout,” Taylor says. “The user can easily determine what type of material is selected and at what speed the blade will move.”

Infinite variable speed is one big advantage over the limited speed options of today’s saws, but DVR also offers improved safety through load spike detection: the controller can sense if a jam occurs during cutting. Conventional induction motors on band saws have no such detection capability, because they don’t have a “brain” controlling their function. “When a jam happens, this technology provides electronic braking, which helps to stop the blade quickly and limit injury risk, Taylor says. “These braking features don’t do damage to the motor, which also helps prolong its life.”

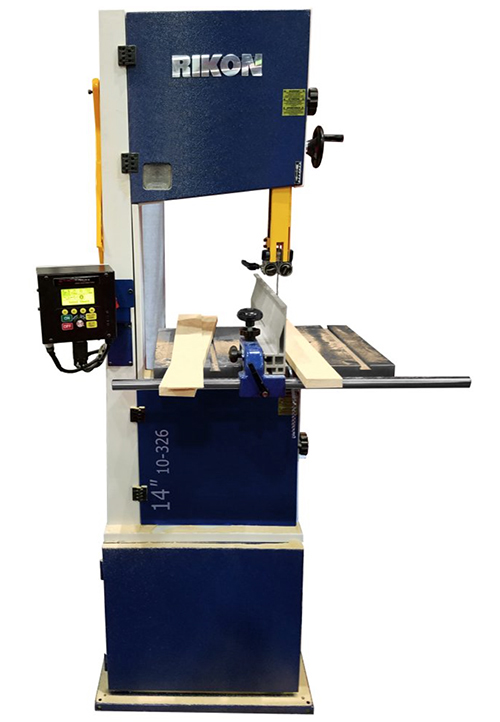

RIKON’s DVR Smart Motor and Controller will first be offered as a 1.75hp Retrofit Kit for six of its 14-in. band saw models, including 10-320, 10-321, 10-324, 10-325 and 10-326 machines plus its RK14CS saw. The kit will include the motor, controller and necessary hardware, and Taylor says the conversion process is easy to do.

“The only components that will be changed are the motor and power switch. We provide step-by-step instructions in our manual on how to remove these components and install the new motor and controller.”

The single-phase DVR motor is suitable for either 110- or 220-volt power input by changing the plug.

RIKON is focusing strictly on 14-in. band saws for this first iteration of DVR retrofit, Taylor says. Next year during the first quarter, RIKON will also offer the 10-326 band saw with DVR already installed (pricing has not yet been determined). The company intends to develop the technology for its larger 18- and 24-in. band saws in the future. Plans are not in the works for DVR retrofit kits for RIKON lathes or other makes and models of 14-in. band saws.

This DVR Smart Motor and Controller kit (model 13-926) will reach RIKON retailers in November and sell for $629.99. The control box will be covered by a 2-year warranty, and the motor will have a 5-year warranty.

“By adding a Striatech smart switched reluctance motor, your RIKON 14-in. band saw will be better than ever before,” Taylor says. “Unlike previous band saw motors, it’s infinitely variable and offers continuous torque. This means a beautiful finish on your workpiece and a much easier user experience.”

Editor’s Note: Joe Taylor wishes to thank Jen Greco, marketing executive at Striatech, who provided consultation for this article.

Learn more about the DVR Retrofit Kit by clicking here.