How do I tell regular hardboard (Masonite) from tempered hardboard, and what are the differences between the two?

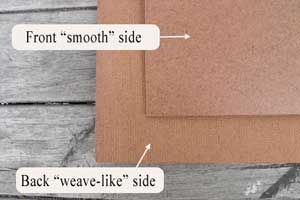

Timothy Knight: Hardboard is a generic term for a panel manufactured from cellulose fibers pressed together under extreme pressure and heat to a density of at least 31 lbs per cubic foot. The natural lignin in the wood fibers acts as the bonding agent. The wet process using steam originated from the original patent of William H. Mason in 1926 and 1928. Most all hardboard today is manufactured using the “Mason” process, although hardboard made by the Masonite Company itself is sold under the trade name “Duron”. Tempered hardboard adds an additional step of coating the hardboard with a thin film of linseed oil and baking the board to give more water and impact resistance, hardness, rigidity and tensile strength. Tempered hardboard is used almost exclusively in construction siding. The manufacturer should be able to tell you if their particular hardboard is tempered or not.

Carol Reed: Visually, tempered hardboard is much darker, due to the oil.