Sometimes a familiar form, such as a low table, can take you by surprise. You know with just a glance that this little project is a coffee table — its height and shape clue you in immediately. But then the details start to catch your attention. Its edges are thick and irregular. But there are also several strong rectangular shapes that jump out at you: the inlaid stripe of ash lumber, the glass plate in the center and the black, tubular steel legs.

And then there is the walnut lumber. Thick, live-edged with bark inclusions, its grain wraps around the table, highlighting heartwood and sapwood. Those light and dark colors are amazing — even surprising. We found the walnut at a local sawmill, which is a fun task in and of itself. While the table plan was designed in advance, the stock we found for it definitely influenced the final result, and its irregular edges were always an important consideration.

Making the Templates

When working with irregular lumber like this, one key to success is to somehow create dead-straight edges from which to form your joinery. Then, there is the additional challenge of getting the serpentine live edges to meet at the mitered corners in a way that is attractive and not distracting. In order to solve both of those problems, we made templates for the tabletop pieces from 1/4″ material. Making a template for each of the four pieces enables you to check them for a correct fit.

After allowing the lumber to acclimate to our shop for a week or so, we used a draw knife to cut away the bark from the edge of the board. Then we used the templates to mark the lumber for the four top segments in preparation for cutting these pieces at the miter saw. Notice that we laid them out sequentially in the order of edge piece/end piece/edge piece/end piece. That ordering will allow the figure of the wood to flow around the tabletop. At this point we did not miter-cut the stock, just broke it down into blanks by cutting straight across the width. Mark the workpieces on their ends (we used numbers) to help assure that you’ll have them properly aligned when assembled.

With the stock cut to more manageable size, the next step was to face-joint the blanks and then plane them to a uniform thickness of 1-5/8″. After that, it was time to do some more advanced joinery.

Cutting Straight Edges and Miters

Once again we grabbed the templates to mark the stock for the next machining steps. Be very careful to locate the pointed tips of the miters dead-on the waney edge of each blank; this is the best way to get a reasonable alignment of those irregular edges when you assemble the tabletop. (Even so, a bit of carving will likely be needed to terminate the miters perfectly.) We marked the straight inside edge and the miters on each piece. Note that when working with walnut, a white marking pencil makes these layout lines much easier to see.

With the pieces all marked, it was time to cut the straight edges that will form the interior rectangular opening when the table is assembled. We used a track saw — a circular saw that has a special aluminum track to guide it — to form those straight edges. A regular circular saw with a shop-made guide would work for the task as well. What is critical is that these cuts are straight and square to the machined faces of the walnut. For that reason, it is very important to have a sharp saw blade and to take your time. Let the saw do the work as you cut — don’t force it. The straight cut edges become the fixed starting points from which the miter cuts will be registered. Any significant deflection of those edges will make forming accurate miters much trickier. (And most of us think that miters do not need to be any trickier … ever.)

Cutting those tricky 45-degree miters is next on the agenda. As with any closed mitered frame, these cuts are critical to bringing the shape together. They will form those straight edges into a rectangular opening, and they will do the same for the ash inlay we will install later in the process.

First take a moment to transfer the number notations on the end of each piece to the face, since you will be chopping the existing numbers off the boards. We then used hash marks, crossing each miter line, to also help keep the orientation of the parts clear.

Any time you are going to be cutting expensive stock like this walnut, set up the saw carefully and make test cuts on scrap material first. In our case, checking the accuracy of the detents on the miter saw required cutting a complete set of miters. We used MDF for that task. The good new for us was that the saw was dead-on when swung to 45 degrees left or right. The earlier advice about using a sharp saw blade is doubly important here for the miter saw: these are heavy-duty cuts, and you need all the saw’s elements working together to cut well. Now go ahead and cut the miters, using the saw’s hold-down for improved safety and accuracy. Once cut, check how the parts fit together. You will probably have to adjust the miters a small amount … it just goes with the territory.

After that’s done, it’s time to start sanding the faces of the stock, but first study the figure in the wood. You still have the option of choosing one face or the other as the tabletop’s show face. But before you can get busy sanding, transfer the hash marks back to the ends of the boards so you won’t lose them as references during sanding.

Drum Sanding Convenience

We used JET’s new compact 1hp 10/20 Drum Sander for the first time on this project. Don’t let its small footprint fool you. It worked like a full-sized self-feeding unit, producing excellent results without a hiccup.

We sanded both faces of the tabletop pieces, first to clean up any areas of tearout from the miter cuts and then to get a good look at the wood’s figure. There had always been a presumed “top” of the tabletop as we were working on it. That was mostly the result of looking at the waney edges and deciding which orientation would look best. As it turned out, this continued to be the determining factor — the board’s figure on both faces was pretty similar.

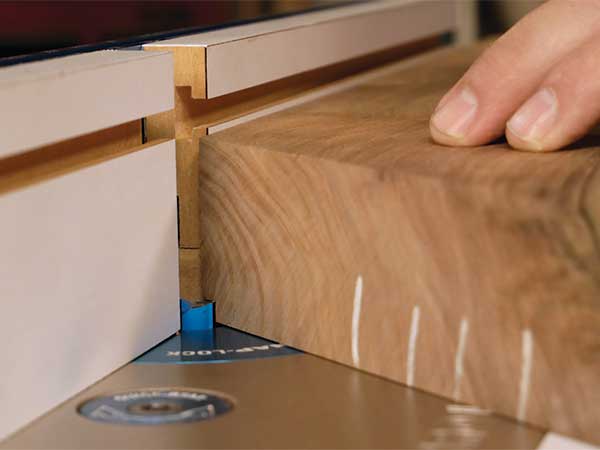

With sanding behind us, it was on to the router table to do a bit of additional machining. The rectangular opening in the center of the tabletop is covered by a glass insert, and that insert sits in a rabbet that encircles the opening. We made ours 1/4″ wide by 1/4″ deep. You’ll also need to rout a 1″ wide, shallow groove for the inlay. We used a 5/8″-diameter straight bit for both operations. Open up your router table’s split fence so that you can expose only 1/4″ of the router bit, and then set the depth to 1/4″. Use a bit of scrap to test the cut and, after dialing it in, go ahead and mill all of the rabbets on what will be the top of tabletop. (You are committed now!)

We used ash lumber for the inlay species, but maple or even a dark wood like wenge would look great, too. Rip some strips 1″ wide by 1/8″ thick from your inlay material. We took the extra step of running them through the drum sander to make certain that they were entirely uniform.

Now, back at the router table, close the fence facings and slide the fence 2″ back from the router bit. Lower the bit until it is a strong 1/16″ above the table, and give that setup a test run. (Keep that scrap piece close by for now.) When you are satisfied with the cut, grab the walnut and plow a groove, orienting the straight edge of the pieces against the router table fence. Once you are done with that, move the fence an additional 3/8″ away from the bit and, grabbing the scrap stock you saved a minute ago, plow the remaining width of the groove. Test the inlay strips in the groove and adjust it as needed. The strips should fit snugly. If they do, glue the strips in place and let it fully cure.

Here again was another time the 10/20 Drum Sander proved its worth: we used it to sand the inlay flush to the top of each mitered piece. Then, a Japanese hand saw made quick work of trimming the ends of the inlay pieces flush to the mitered ends of the walnut.

Assembling the Top and Finishing Up

Although these mitered ends are wide and thick, providing lots of glue surface area, we still thought the joints needed to be reinforced with some loose-tenon joinery. We chose the Beadlock® system for that task. Drilling a series of side-by-side holes creates the mortises that fit Beadlock’s prefabricated tenons quickly and easily.

As always, before you glue this tabletop together, you need to do a dry assembly. It allows you to test the fit one last time and practice with your clamps. When you are ready, glue and clamp the parts, allowing the joints to dry overnight. Scrape off any squeeze-out, however, when the glue gets rubbery after 20 minutes or so.

When the clamps come off, it’s time for another round of sanding. We sanded the top up to 400 grit so that the wood almost looked polished without a finish applied. And speaking of finish, for air-dried walnut like we used, you can’t beat Watco Oil to enhance the color. We wiped on five coats, allowing it to cure and rubbing it down with 0000 steel wool before the last coat.

Tubular-steel legs were an early decision for this project. They harmonize nicely with the tabletop’s rectilinear shape. Once installed, we knew the hardware was a good choice. That done, we set the glass into place for a lovely last touch. This table is practical, beautiful and full of surprises … just as we had hoped.

Hard-to-Find Hardware:

U-Shaped Welded Steel Table Leg Set #40716