I hate to admit it, but I really do like things that have a “wow factor,” like desks with secret compartments, cabinets with fancy marquetry… and the box shown above and at the left. This box has a little surprise: When you open the drawer, the top of the box retracts like a mini roll-top desk. The top is a tambour, with a series of narrow slats glued to a flexible canvas backing. The tambour slides in a curving track in the sides of the box, and its bottom edge is directly attached to the back of the drawer. When you pull the drawer open, the tambour automatically opens, revealing a shelf inside.

All the components necessary for building the tambour box are listed in the Material List and shown in the Drawings. The box is sized to be useful as a jewelry box, a case for storing watches, sunglasses, etc., or as a desktop caddy to keep pens, erasers and other office supplies organized.

The Sides and Tambour Track

To start this project, cut out the two sides of the box from any nice hardwood stock planed down to a final thickness of 5/8″. Cut out two partial discs that are exactly 7-1/2″ diameter by putting the point of a compass exactly 1-1/2″ from the square edge of the stock. After rough cutting the discs out with a band saw or jigsaw, stick them together using double-stick tape or adhesive transfer tape, then use a stationary disc or belt sander to sand them to final size. Separate the parts, remove the tape and mark the inside face and front-facing edge of each part.

Use adhesive transfer tape or double-stick tape to temporarily secure the template in place on the inside face of one of the box sides, carefully positioning the template’s bottom edge flush with the bottom of the side and its front edge flush with the front of the side.

With the plunge router set to take a 1/4″ deep cut, rout the track starting at the top of the template. As you move the router around the template, take care to keep the guide bushing tight against the template’s edge. When you reach the end of the channel, raise the bit and switch off the router.

Before removing the template, mark its angled end (just below where the channel starts) onto the side with a fine pencil line. Now remove the template, peel or rub off the tape, and attach the template to the inside face of the other box side, reversing it front-to-back so that you’ll rout a mirror image of the track. Rout and mark as before.

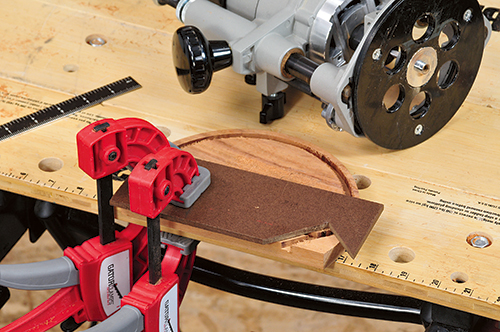

There’s one more bit of track routing you’ll need to do, to allow the tambour to be installed or removed from the assembled box. Make the second 1/4″ thick template following the pattern shown in the Drawings. Line up the template’s angled notch with the pencil mark you made earlier and set its lower edge so that it overhangs the bottom of the box side by 3/8″. Clamp the template and side down to a bench top, taking care to locate the clamps so they don’t interfere with the router’s base. Then rout the short exit track, starting the router at the bottom edge of the template.

The Bottom and Shelf

The box’s bottom and shelf are made out of 3/8″ thick stock. Cut out both of these parts from the same hardwood as the sides, so they’ll match. Bevel cut the front edge of the box bottom to 15°, so that it’ll match the slope of the sides.

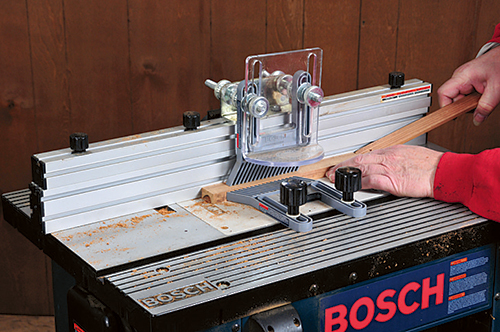

To keep small items from rolling off the back of the shelf and interfering with the tambour, the shelf’s back edge receives a raised cap strip with a cove cut into its upper, front facing edge. Cut the cove into the strip using a 3/8″ diameter core box bit in your router table, then glue it to the back edge of the shelf. The shelf also receives a small bead strip, to keep small items from rolling off its front edge. Cut the 5/16″ diameter half-round bead using an edge beading bit in the router table. Set this strip aside for now.

The shelf and bottom are secured to the sides using # biscuits. Set up the biscuit joiner to center the slots thickness- wise in the ends of the shelf and bottom, locating them as shown in the Drawings on the opposite page. Cut the biscuit slots in the box sides so that the bottom and shelf will be positioned as shown in the Drawing.

Sand the parts smooth, leaving the edges of the ends crisp where they’ll join the sides. Also sand the inside faces of the sides, paying special attention to smoothing the inside surfaces of the routed track. Don’t round over the edges of the sides just yet.

The Drawer

The space formed by the sides, shelf and bottom of the box serve as a housing for the box’s drawer. The drawer is sized to fit snugly in this space, yet slide smoothly in and out of it. Cut out the parts for the drawer following the Material List. You can use just about any wood for the drawer box parts, but for the drawer front and pull cap, use the same hardwood that matches the rest of the box. You can cut the drawer bottom either from solid stock or 1/4″ hardwood plywood (which is typically about 3/16″ thick).

Cut a 3/16″ wide, 3/16″ deep groove on the inside face of both sides and the drawer front, using either a table saw or a router table. Space the lower edge of the groove 1/4″ up from the bottom edge of each part. Cut or rout a 1/8″ wide, 5/32″ deep dado into the inside face of the two sides. Space these grooves 1/2″ from the back ends of the sides. Next, cut the joints on the ends of the drawer back. Using a 1/4″ straight bit in the router table, rout a rabbet to form a 1/8″ wide, 5/32″ long tenon on each end of the back.

To create clearance where the tambour attaches to the drawer, cut off the back lower corner of each side at a 45 degree angle. Then, using a sharp chisel, trim the small triangular piece above the miter cut flush with the depth of the drawer bottom groove as shown.

To shape the drawer pull strip, first use a 3/8″ diameter core box bit to take a 3/8″ deep cut into the lower edge of the strip . Set the table’s fence so that the cove is spaced 1/4″ back from the strip’s front edge. Trim the strip on the table saw, to form the 1/4″ thick section that will be glued atop the drawer. Use a 1/2″ radius roundover bit in the router table to shape the top edge of the pull, then set the strip aside.

To join the drawer sides to the drawer front, I hand cut halfblind dovetails with 5/16″ long tails and 5/16″ deep pins. Although there aren’t many dovetails, it takes a lot of fussing and patience to get tight, clean joints, so you may opt to join these parts using a simple rabbet joint instead.

After sanding the inside surfaces of the drawer parts, do a quick dry assembly to make sure everything fits together correctly. Now glue up the basic drawer box, sliding the drawer bottom in place and tacking it to the lower edge of the back side. Check to make certain that the assembly is square before leaving it clamped up to dry for an hour or so. When the glue has dried rubbery hard (but not rock-hard), remove the squeezeout with a cabinet scraper or chisel.

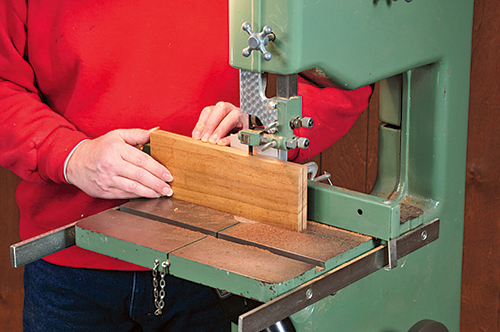

After clamping up the dry assembled box, slip the drawer into its housing to check the fit. There should be about 1/32″ of side-to-side play between the drawer and the sides. If the fit is a little too snug, use a block plane to trim the sides slightly. Now set the drawer front flush with the edge of the sides and mark the sides’ curve on each end of the front. Use a hand plane to shave the drawer front until its curve matches the sides. After sanding the front smooth, glue the pull strip to the top edge of the front. After the glue has dried, cut away the outer parts of the pull strip on the band saw, following the curve shown in the Drawings. Use a spokeshave or cabinet scraper and sandpaper to fair in this curved cut with the drawer front, then finish sand the rest of the drawer. Round the top edge of the pull with a block plane and sandpaper, to increase the radius of its curve to about 3/4″ (which presents a more elegant look). Also, ease the bottom inside edge of the pull strip, to make it more “finger friendly.”

Making the Tambour

I’ve saved the most interesting task for last: making the tambour that forms the box’s retracting top. To make stock for the tambour’s slats, resaw enough 11-1/2″ long 4/4 boards to make twenty- four 1/2″ wide slats as shown in Figure 10. Plane each of the resawn boards down to 3/16″ thick, then crosscut the boards exactly 11-3/16″ long, making sure all ends are cut square. Rip the slats to 1/2″ width on the table saw, using a quality blade that leaves nice, clean-cut edges. To save time, I adhesive transfer tape the boards together, and gang cut four slats at a time.

Create a frame for assembling the tambour by nailing or screwing 1/2″ thick scrap strips to a flat piece of 1/2″ or 3/4″ plywood. Make the inside dimensions of the frame 11-3/16″ wide by 12″ long. Now set the best 21 of the slats you cut into this frame, with their “good” sides facing down. Add an extra slat, covered with masking tape after the last good slat. Press the tambour tightly together by driving three pairs of small wedges against each other between the last taped slat and the frame.

An 11-1/8″ x 11″ piece of lightweight (9-11 oz.) canvas duck fabric makes the flexible back of the tambour. Carefully spread a light, even coating of yellow or white PVA glue onto the slat assembly and press the canvas down onto the slats. Align it with the frame and wipe off any excess glue from around the edges. To set the glue quickly (to keep it from seeping down between the slats), use a household iron on a medium setting (no steam) to heat the canvas. Work the iron over the surface for a minute or so, applying only light pressure and keeping the iron moving at all times. Let the tambour cool for about 10 minutes, then remove the tambour from the frame and bend the joints between all the slats open, to assure they’re not stuck together. Now set the tambour aside overnight, to let the glue fully cure.

The next day, trim back the canvas at the sides of the tambour 3/16″ from the ends of the slats. On the band saw, trim 7/16″ off of both ends of the last slat (at the rear of the tambour), so it can be attached to the drawer. Also reduce the width of the first slat (at the front) to 5/16″ wide using a table saw or jointer.

To finish off the tambour, the front slat receives a cap strip, cut to the size and profile shown in the Drawings. Glue this strip in place, centering it on the length of the slat (Figure 15). Now sand the entire tambour surface smooth, easing the edges between slats and rounding their ends slightly. Wax the slat ends a little, so that the tambour will slide more easily within the track.

To attach the tambour to the drawer, dry-assemble the box and clamp the sides, bottom and shelf together (Figure 16). Slide the drawer into place and turn the whole thing upside down on the bench. Slip the tambour into its track with the capped end first.

With the drawer held fully closed and the tambour cap tight against the pull strip, press the last trimmed slat against the drawer bottom and drill a pair of small diameter countersunk holes into the edge of the drawer back, spaced about an inch from the ends. Drive 3/4″ long #6 screws into the countersunk holes, then flip the assembly over and make sure the tambour retracts smoothly when you pull the drawer open.

Assembly and Finishing

After taking the dry assembly apart, glue the bead strip to the shelf, locating it parallel to and 5/16″ back from the shelf’s front edge. Glue the shelf, bottom and sides together, applying just enough glue to coat the biscuits and slots thoroughly. After the glue dries, remove any squeeze-out and sand the entire box, rounding over all edges slightly with sandpaper.

You can apply any finish to the box, but an oil finish makes it much easier to finish the tambour slats, so that is my recommendation. Reconnect the tambour and drawer, and your box is ready for use. With any luck, you’ll hear a little “wow” the first time somebody opens it.