Steam bending wood is not an exact science, despite it being a time-honored process. Wood in most cases just wants to retain its current shape. That’s what lignum and those other wood fibers are designed to do. Here’s a truism you need to know: if you are going to attempt to steam bend wood, you are going to break some pieces. It’s inevitable. But with that said, it is a way to make some beautiful woodworking projects, like these coat hooks. They’re a great starter project for getting your feet wet in steam bending, because you’ll learn about springback, creating two different- shaped curves on a single piece of wood and how to make a two-piece form. Make while you learn — it’s a win-win!

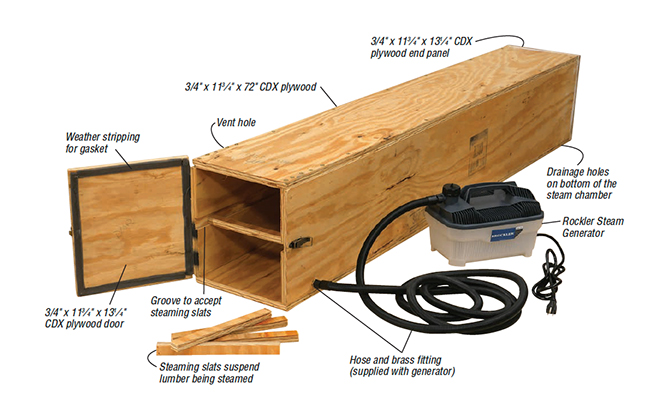

As to the steam generator, Rockler sells a great one. The company’s Steam Bending Kit is safe to use and has all the pieces you need to get started. You can make your own, but there’s the risk that it could explode — something to definitely avoid! The steam generator needs to be connected to the steaming chamber with a hose. The chambers themselves can be made from solid wood, CDX exterior plywood (our example on the opposite page) or PVC designed for very hot temperatures. (Some schedules of PVC will go limp when treated to steam.)

The chamber we made is much larger than we needed for these little hooks, so we added a movable chamber divider. Next time we may be making some long table legs or sled runners instead … who knows?

What About the Wood?

Air-dried wood is a must; the kiln-drying process hardens the lignum when it heats the wood. Green wood is your best bet — wood that has a moisture content of 20 to 30 percent bends most easily. While there are some conflicting opinions as to which species of wood is best for steam bending, most lists include white and red oak, ash, elm, hickory, beach and birch.

Sourcing green hardwood can be a bit of a challenge, but local saw mills will have a supply. Also, you can look up local woodturners who usually have sources for green lumber. If you are adventuresome and you own a band saw, you can harvest your own pieces from recently downed logs and limbs.

Avoiding a break when you bend is the goal. Your bending blanks should be wider than they are thick, and the bending face should be plainsawn. You’ll get the best results when the grain runs the entire length of the blank’s edge. If the grain runs off the edge, be sure to orient that toward the “inside” of the curve. Here are three tips that proved very useful for us: 1) Sand the blank smooth before you bend it; 2) Chamfer the edges with a block plane and 3) Soak the blank in water with Downy fabric softener. All of these steps reduce breakage.

Steam Bending Guidelines

- Presoak wood several hours in water/Downy liquid fabric softener.

- Convex and concave curves on one piece require a two-part form.

- Use air-dried lumber so its lignum is not hardened by heat.

- Lumber with 20 to 30 percent moisture content bends best.

- Lumber drier than 10 percent will not bend without breaking.

- Use plainsawn wood that’s wider than it is thick.

- Prepare blanks with vertical grain running the length of the edge.

- Choose straight surfaced wood without knots, rot or other flaws.

- Overly long workpieces helps with leverage when clamping.

- Steam one hour per inch of wood thickness.

- You may need to re-steam large bends (15 minutes per re-steaming).

- Once bent, allow to cool for one hour, then move to a drying form.

- Expect some springback once the wood dries, and plan for it.

Making the Bending Form and Hook Blanks

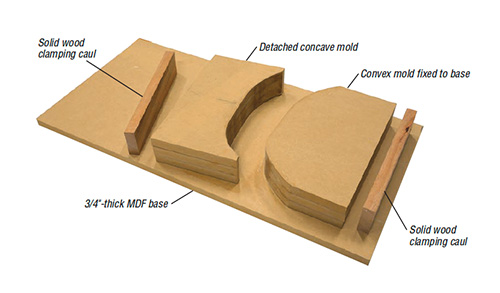

First, you need to make the bending forms. We used 3/4″ MDF, but Baltic birch plywood or solid wood will also work. We’re providing drawings of the hooks’ inside and outside curves and their ovoid shape on a free downloadable PDF.

Cut two pieces of 3/4″ stock 7″ wide by 11″ long, and transfer the two curved shapes for the bending mold onto the pieces. Take them to the band saw and cut as closely to the lines as you can. Then use a drum sander or stationary belt sander to refine the lines. Set the pieces flat on a worktop 3/8″ apart and see if their curved edges align well. If they do not, use a sander to adjust the profiles. These are your bending form templates.

Use the templates to create the mold pieces from six 3/4″ x 7″ x 11″ blanks. Make three of the concave and three of the convex pieces. Carefully align the curved faces for each form, gluing them together. We secured one of the forms to an additional piece of MDF for a base so that only one of the two curved forms would be able to move when clamping up steamed parts.

With that done, now it’s time to make the hook blanks. Ours are 3/8″ x 2″ x 11″ red elm, but the other hardwood species mentioned earlier would be just as good. We cut them from a section of a log, and it was admittedly a challenge to get pieces with the grain running correctly. We needed three pieces for the coatrack, so we made five blanks to allow for potential fractures.

Once roughed out, we planed and sanded the blanks smooth. Chamfer their edges, then soak them in water with a bit of Downy fabric softener. Experienced steam benders swear by Downy. It apparently softens the lignum. Who knew?

Turning Up the (Steamy) Heat!

Our steam chamber has grooves on the inside that allow us to insert adjustable slats that suspend the hardwood blanks in the middle of the chamber. We also installed a chamber divider to limit the steaming area inside. Plugging in the steam generator, we waited for about 15 minutes for it to start making a substantial amount of steam, then another 30 minutes to be certain the chamber was up the correct temperature and humidity. We put one hardwood blank into the chamber and set a timer. Steam the wood about one hour per inch of thickness. As these pieces are approximately a third of an inch thick, 20 to 25 minutes of steaming was required.

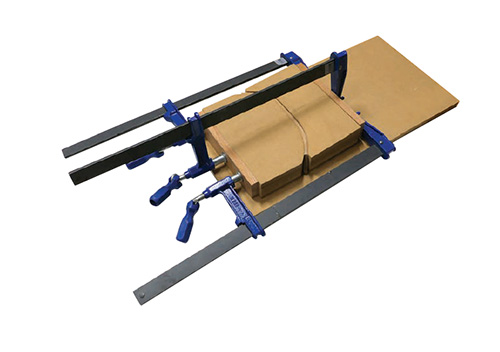

Before the piece is ready to bend, get three strong clamps ready to go. When the timer rings, carefully open the chamber door and stand back — that steam is hot! Unplug the steam generator. With gloves on, place the blank inside the bending forms and center it. Install a clamp in the center of the forms to start the bending process. You don’t need to move quickly, but don’t dawdle; the blank begins to cool immediately. Using the other two clamps, continue to squeeze the forms together until the blank is bent to its new shape.

The bent wood needs to stay in the forms for at least an hour. While it is in there, make a cooling form that matches just the concave side of the bending form. Once the piece has cooled for an hour, take it out and clamp it in the cooling form. Let it set at least overnight. When you unclamp it the next day, it might spring back a bit … that’s to be expected.

Complete the coat hook shaping process by tracing the ovoid shape found in the Drawing onto the face of the bent blank. Cut out the coat hook shapes on a band saw or scroll saw and sand them smooth. We chose a 1/2″ x 2″ x 24″ piece of wenge for a backboard. To mount the assembly to the wall, we drilled two holes 16″ apart.

Then we placed the hooks evenly along the 24″ board, avoiding the mounting holes. Attach the hooks with a spot of glue and two #8 x 1/2″ black washerhead screws. When the glue cures, apply a few coats of Watco oil finish, and fasten your new coatrack to the wall.

We hope that this simple steam bending process and project may entice you to try it out. It’s a great way to expand your woodworking horizons by adding more curves!