This clock project is fast and easy to make. It’s a perfect gift project because once you’re set up, you can make multiple clocks very efficiently. We used Rockler’s Compact Router Ellipse and Circle Jig to rout the circle shape and Rockler’s Signmaker’s Template Kit in the 2-1/4″ State Park Font to form the numbers.

Making a clock is a fun project that doesn’t necessarily require a lot of tools. You can make the clock face out of just about any piece of lumber. All it needs is a hole for the clock mechanism to fit through. You can also be as creative as you like with the clock face. Keep it simple and clean with a clear finish and no numbers. Or enhance it with applied numbers or techniques such as carving, painting or woodburning.

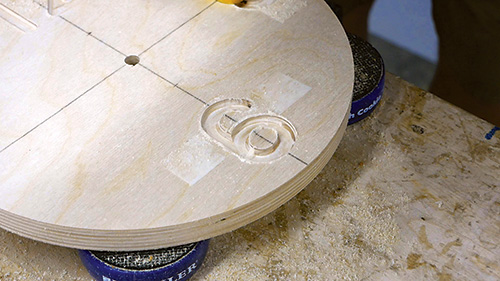

Step 1: Cut a 3/4″-thick x 12″ x 12″ piece of plywood, or glue up a solid panel for the clock face. We used a circle-cutting jig and a compact plunge router for the next step. Mount the jig’s base to the center of the workpiece. Attach the circle-cutting jig arm to the base of the router, and install a straight bit in the collet. Position the pivot point on the jig to cut a 10-1⁄2″-dia. circle. Now set the router to a 1/4″-deep cut, and rout the circle in three passes, lowering the bit depth by 1/4″ after each pass.

Step 2: Drill a 5/16″-dia. hole through the center of the clock face to accommodate the clock movement shaft.

Step 3: Set up the Interlock Signmaker’s Templates to rout the twelve, three, six and nine o’clock numbers one at a time. Connect an extra spacer on each side of the numbers to provide additional support for the router base.

Position the template so that the outside edge of the number is 1/2″ in from the edge of the clock face. Secure the templates with double-sided tape under the templates or painter’s tape over the edges of the templates.

Step 4: The six and nine require two templates to complete the shapes and must be cut in two passes. The templates for these numbers are lettered A and B.

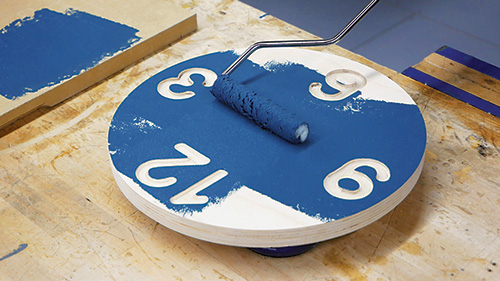

Step 5: Next, apply the finish of your choice. We used a low-nap roller to apply paint to the surface and left the routed numbers natural.

We made a second clock out of bamboo plywood and brush-painted only the letters. We then applied two coats of satin water-based poly to all surfaces.

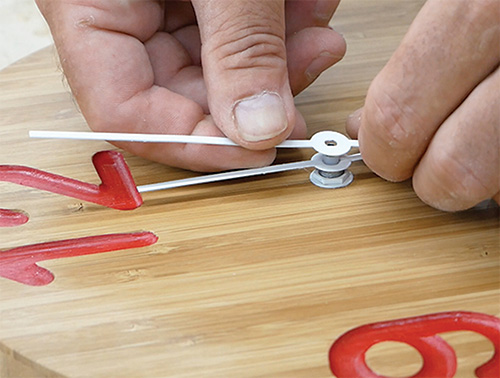

Step 6: The final step is to install the Mini Quartz Clock Movement clock mechanism and hands as instructed on the product packaging. The Straight Clock Hands we used were black, so we painted both hands, the washer and the nut to complement each clock. Insert the movement’s stem through the center hole from the back, secure it with the washer and nut and attach the hands to it.