Recently I contacted Barry Schwaiger, director of product development at Powermatic, to learn more about the company’s new flagship 4224B lathe. Just a few minutes into that phone conversation, I happened to call the popularity of woodturning these days a “renaissance.”

That term just didn’t sit right with Barry. He let it go at first, then circled back around to it later in our conversation.

“A renaissance suggests something that’s gone away and then come back…but woodturning never went away. It’s just gaining more popularity than I’ve ever seen before!”

So, I asked for Barry’s thoughts on the matter, because I’m flat-out curious about it. We in woodworking publishing are hearing a lot of buzz about woodturning these days: popular symposiums, new lathes and turning products, growing numbers of turning clubs and, of course, plenty of turning project photos submitted to our offices. We dedicate a regular department in our print magazine to woodturning, as you probably know. But it hasn’t always been this way, so why does woodturning seem to be taking center stage these days?

Barry didn’t have statistics, but he chalks it up to a couple of educated hunches. For one, woodturning enables someone interested in woodworking to get into the craft with only a couple of tools. If you have a lathe and band saw, you’re pretty much set for turning lots of things. That’s the sort of woodworking that makes a lot of sense in these budget-challenged times. He thinks that retiring baby boomers, with some expendable income and more free time, are also helping to feed the current swell of turners heading to their firewood piles for inspiration. But he thinks something more distinctive and special is at work here, as well: woodturning is now being seen more clearly as art.

“It seems to me that there’s a growing interest in artistic expression, and woodturning feeds that like no other area of woodworking can. Most woodturners I talk to are genuinely inspired by what they make, and so are artists. There’s a common thread there that makes woodturning a great medium for new forms of art.”

Whatever the reason may be for woodturning’s vibrant popularity these days, turners have always been pivotal to Powermatic’s business. In fact, wood lathes were one of the company’s inaugural products following the first machine, a surface planer. Schwaiger says wood lathes predate shapers and joiners in Powermatic’s history, and he considers wood lathes to be its most strategic category today over all other tool types.

It’s a category for Powermatic that seems relatively insulated from the fits and starts of a volatile economy. Schwaiger reports that, since 2008, lathe sales “have grown absolutely for us while other tool categories followed recessionary trends.

“Three issues ago in our eZine, you may have seen my write-up of the new Powermatic 4224B Wood Lathe. If you didn’t catch it then, click hereto read more about it. The machine, which retails for $7,499, was just brought to market this summer. I couldn’t help but wonder, even while I wrote that Tool Preview, how the company could strategize launching one of the more expensive products I’ve ever reported on for our magazine in these barely post-recessionary times.

But Schwaiger says Powermatic has looked at the 4224B lathe differently, from the first day it started planning this new lathe about six years ago. It was a tool engineer’s dream from the get-go: design the ultimate Powermatic wood lathe with the best of all features, “and when we finished the design, we totaled up all the costs. Even at a premium price, we knew this lathe would be well worth it, so we went ahead.”

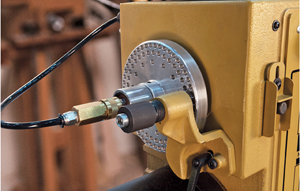

Barry reports that the new 4224B takes everything that has made its popular 3520B lathe so successful and builds on that platform. He’s most excited about the integrated vacuum system, the onboard lighting and accessory outlets and improved indexing features. The machine also has a larger three-phase motor and infinite variable speed. The attributes of the new lathe are definitely turning heads as it has debuted at recent turning shows.

“Lately I’ve have turners come up to me and ask, ‘What’s this lathe cost?’ I tell them, it costs an arm and a leg. But once I walk them through all of the features and tally up what each of those improvements would cost if added to another machine, most of them end up saying that we’re selling our new 4224B for a pretty good price, all in all.”

Powermatic has never offered other than full-size lathes, but as more and more companies are expanding their lathe offerings with mini and midi models, would Powermatic ever consider doing the same thing? Schwaiger admitted that building smaller lathes “is always in the back of our minds,” but there’s nothing on the drawing boards yet. He did add a teaser, though: once the right feature set is available for a smaller machine that embraces the Powermatic brand, “we would likely pursue it further.”

Schwaiger previously reported, in my “State of the Stationary Power Tools” article (August 2012 Woodworker’s Journal, page 50), that Powermatic was intending to set new standards for its products, regardless of price. The new 4224B lathe is a prime example of this philosophy: design with premium features in mind for the turner who is willing to accept nothing less. Then set the price. So far, Schwaiger says the approach is proving favorable to customers looking for the very best they can afford.

If you happen to own the classic 3520B lathe, which sells for about $3,500 less than the new ultimate lathe, or if you’re in the market for one at some point soon, have no fear about its future or availability. Schwaiger assured me there’s no danger of it disappearing from Powermatic’s product line. “It’s our ‘Ford F150’ of lathes, and it’s been a great machine for many, many turners since we first unveiled it.”

But, in the company’s goal of being a category leader, “we’re very proud of the new 4224B lathe, and we’re making no apologies about its price tag. This is not the lathe for everybody, but it definitely raises the water level of our 3520 machine. It’s our showroom car.”