Some accept it grudgingly, calling it “plastic-looking,” while others embrace it as the greatest thing since sliced bread.

Wildly popular among hobbyist woodworkers, polyurethane is durable, easy to apply, and comes in both water-based and oil-based versions. Oil-based polyurethane (front of lead photo) adds an amber color and chatoyance. water-based polys (back of lead photo) are clear.

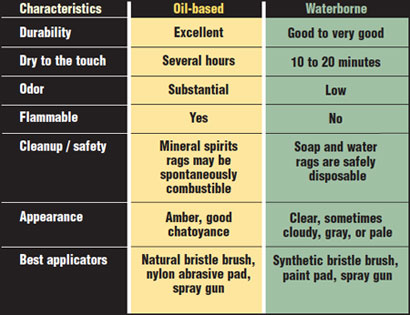

Like many finishes, polyurethane is named for its primary resin, though some cans labeled “polyurethane” also contain other resins. Resin is what remains behind to form a film once the solvent has evaporated. The resin defines the nature of the coating. In general, polyurethane or urethane resins (the terms may be used interchangeably) provide finishes with good durability, including resistance to heat, abrasion, chemicals, stains, and solvents. Polyurethane is tough enough for kitchen tables and cabinets, bathroom vanities, walls, doors, floors, all types of furniture and virtually any woodworking project. Woodworkers mainly use either oil-based or waterborne polyurethanes. Both have good qualities, but they are very different in many ways, giving rise to a hotly debated disagreement over which is superior.

The primary differences between oil-based and water-based polyurethanes relate to how they are made. Oil-based, whose proper name is “oil-modified urethane,” is produced by reacting common finishing oils, like linseed oil, with a chemical that causes the oil to form larger molecules. A good rule of thumb is that larger molecules mean more durable finishes.

The Characteristics of Oil- and Water-based Polyurethane