Paul Morrison grew up on a farm, where “you were expected to learn whatever was needed; you just work hard and do it,” and had a grandfather who was a cabinetmaker. He traces those influences back to the beginning of his interest in woodworking, but after high school, it just seemed to be a “natural fit” to parlay his interests in math and science into a career as an engineer, “with woodworking in the hobby category. I was thinking some day, I’d do it in retirement.”

It didn’t quite work out that way: Paul is now the proprietor of The Wood Cycle of Wisconsin, a family-owned, full-service woodworking operation. The business takes a project from its start, as wood in tree form, to finish. “The Wood Cycle name is part of that,” Paul said.

It all started, because, as someone with Dutch heritage, “Dutch don’t buy wood, we buy a sawmill,” Paul said. The Wood-Mizer sawmill he bought for his woodworking hobby several years ago was producing more than enough wood for his own projects, so procuring wood and building projects for friends and others became a side job, in addition to his engineering work.

“One day, someone said, ‘This is obviously your passion, so why are you sitting at a desk?'” Paul said. After some time contemplating whether, “If it’s a job, does that change things?” Paul concluded that he would get just as much enjoyment of making things for others as he did for himself.

From the beginning, Paul set up Wood Cycle as a full-time business, noting that with the investments in equipment and lumber storage, it wasn’t on a scale to run out of his garage, “it was a business with employees, rather than a one-man show.” He started out with himself and a nephew “with the same passion for woodworking, the same hard work ethic” as employees. They’ve since added another employee.

They started out with the business on a converted farmstead, using the old farmhouse as a finishing studio, and a couple of the barns for the rest of the operation. When talking to a neighbor about his business plan in 2008, Paul happened to mention that at some point, he’d need to pull down a shed and get a bigger barn. “He said ‘You need a barn? I have a barn.'” That conversation resulted in moving a 36 x 30 round-rafter barn, which had been slated for demolition, to the old farmstead and consolidating most of the shop operations into it, as well as adding a showroom. (Sawmill storage and lumber remains in one of the old barns; the old farmhouse is now an office.)

Having everything on one site, Paul said, is helpful in keeping track of individual customers’ wood. A lot of those pieces have family stories with him, like, “this is the tree Johnny fell out of and broke his arm, and now it’s his kitchen,” Paul said. “We do lot of taking a project from stump to finish; if a tree came down in somebody’s backyard, we’ll put it in their kitchen.”

Having the ability to mill their own wood also gives Wood Cycle a unique perspective: “You have guys who run sawmills who make an occasional project, and guys who are woodworkers who occasionally find a log and have somebody saw it up,” Paul said. “We find chunks of wood that loggers would leave in the woods, or a tree service would cut up; we find pieces with live edges.”

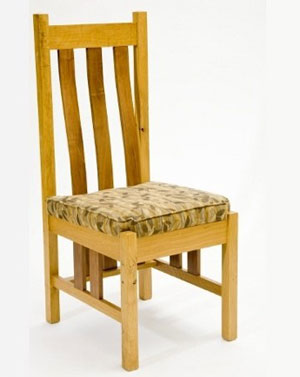

Paul admits that he, personally, does have a bent toward big furniture projects, such as big slab tables. “I like the variety that it gives me, sometimes with the shape of the slab, sometimes in working with the client as to what fits the style of the home — whether it’s Mission, Arts and Crafts, or Shaker…

The variety of the business in general also appeals to him. In one day, he might be making flooring, “essentially pushing wood through machines,” then go cut down some walnut trees, supervise an employee making a table, and later on meet with a client about a kitchen design.

Wood Cycle produces a mixture of furniture, cabinetry, fireplace mantels … “If we find a good client, whatever they need in wood, that’s what we make. Eighty percent of clients are repeat customers within a year. My background is ‘there’s no project you can’t handle; it’s just figuring out how you’re going to handle it and how long it’s going to take.'”

Currently, Paul and Wood Cycle are primarily working with urban woods, with three quarters of their trees coming from the city of Madison or adjoining areas. This means that, while their specialty might be locally grown hardwoods — like walnut, cherry, maple, red and white oak — they also work with lesser-known woods like honey locust, black locust, hackberry, butternut and more.

Perhaps one of the more memorable trees they’ve worked with was a burr oak that recently died: it was one of the trees from the neighborhood where rhesus monkeys that had escaped from the Henry Vilas Zoo in Madison, in 1960 were found. Paul andWood Cycle made a table and chairs for the tree’s homeowner (and were able to get nine big tabletop slabs out of another burr oak tree in the neighborhood that measured 56 inches wide).

They’ve also made accents throughout a house from a walnut tree lost in a tornado, and turned a deceased tree that had been a corporate symbol into a conference table for the business, as well as smaller projects like a turned bowl for the company founder.

All in all, with current efforts that include selling wood; a business plan that take a project, as Paul says, “from stump to finish”; and the variety of efforts at Wood Cycle, looking back over the past 12 years of the business, it’s clear, Paul said, that “one of the big things for us was the sawmill purchase.”