Last week, Rob asked what you all are building these days while we’re hunkered down and getting through these quarantined times. Many of you have answered his call for projects — thank you! Have a gander at what your fellow woodworkers are up to while they practice social distancing and stay well. – Editor

In the midst of grocery stocking and shopping empty store shelves, I decided to increase the capacity of our small pantry. I had some leftover boards from the original 1956 site-built kitchen cabinets in our home that I had been saving for the right project, so I decided to build a door-hung pantry rack. The outer frame is joined with hand-cut dovetails while the shelves are installed with routed sliding dovetails. The hanger rails are joined with biscuits and glue. – Mike Malone

Here’s my functional—not pretty—utilization of recycled “slot” board combined with my French cleat system for adjustable shelves. I’m using it for fasteners and my collection of coffee cans. – Darrell Risley

I made this Missouri Ozark white oak and black walnut (mostly quartersawn white oak) blanket chest for my wife. Some of our great grandmothers’, grandmothers’ and mothers’ hand-made quilts will reside here. Some of the construction features came from my great grandmother’s 1876 oak pie safe, such as the end panel design, the corbels in the front and the way the ends attach to the front and back (with a modern touch or two). The lumber was logged and sawn from a family property, and the dried lumber was milled in my shop where the project was built. The panels are re-sawn and book-matched, quartersawn white oak. The front’s middle stiles and center rail are black walnut to create the “H.” It has a cedar-lined bottom, and the hinges are Rockler’s Lid-Stay Torsion Hinge Supports in rustic bronze. This is my first blanket chest project and my wife loves it. Thanks for all you all do there. – Joe Haskins

While killing time in the shop during this pandemic, I’ve been working on a bookshelf, corner shelf and a bench. – Keith Allen

I’m building a Sam Maloof style rocking chair. The chair is walnut with walnut-and-cherry laminated rockers. Building it has been a real challenge for me and caused me to really stretch my skills, especially to get the leg-to-seat joints correct. I am ready to attach the rockers today, and after cleaning up the leg-to-rocker joints, will start finishing soon. This has been a fun and very satisfying project to maintain my sanity while social distancing. – Charlie Franz

Here are some of my projects, lately. The three-dimensional cross I made from scraps of walnut, cherry and pine. It took a lot of tinkering and reimagining to come up with the final design. I also make memory boxes for hospice patients to use to pass on cherished memories or items to their children or other loved one. I have made more than 35 of these boxes in a variety of sizes, depending on what will be placed in them. This one shown here was made for a woman who had a button collection she wanted to pass on to her two daughters. Be safe and stay well, all. – John Koski

Every year at Christmas my woodworking club makes and donates wooden toys to the Christian Appalachian Project, which distributes them through central and eastern Kentucky. I’ve been using the enforced isolation of late to get a head start on this year’s toys. Attached are photos of a couple of them. – Dick Wesling

I made this cherry wood infinity band saw box for my granddaughter. She is going through some rough times, and I just want to cheer her up. – Mel Johansen

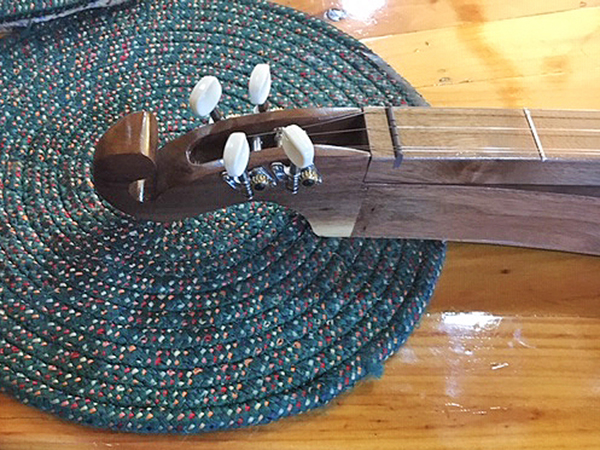

Here are a couple photos of a dulcimer I’ve been working on lately. – Tom Moss

I’ve just finishing building my grandson a “Bullwinkle” out of mesquite. – Orlo Brooks

Living in Montana, I felt lucky to score a 10-ft. slab of 8/4 bird’s eye maple. I mixed it with some 8/4 walnut and designed a bench and an entry table for our home. – Gary Tague

It’s not easy to stay focused with all the 24/7 negative news going around about the corona virus. This is a good time to dive into wood projects such as the framed project I just completed here. I’ve made several of these wooden pictures for the grandkids’ bedrooms. They’re made by selecting a figured plank of wood with knots, etc., like this ambrosia maple, then ripping the selected piece and rejoining at a location to get the figure you want. This one depicts an owl. The grandkids love them, and it keeps me busy. – Steve Brown

When I read your reader project challenge, I just could not resist sending you my latest. This is a new design for me, and I have made two of these since 2018. I call the chair the California West Greene & Greene Chair in Cherry and Curly Maple. It is not done, and with the pandemic in process it may not be done in time to enter it into the San Diego “Design in Wood” competition this year. But, that’s my hope. – Brian H. Murphy

This machine is called a “hoe chucker.” It is used in the logging industry here on Vancouver Island to pile and load logs. I made this model for a retired gentleman who used to operate one, using pictures that he supplied me and from an Internet search of similar machines. – John Baldwin

I just finished a project I was asked to build for a retiring colonel in the Air Force. They wanted a sofa table with a display case in the top that opens to arrange his medals along with a flag case. He also wanted a drawer to display 30 year’s worth of challenge coins and a shelf under the table for more display space. It’s all black walnut, and the only screws are in the hardware attachment. The raised panels are all placed with wooden pegs into the legs. – rhettdawg

Several years ago my wife and I started a nonprofit called Grow Against Poverty to support education and community development programs in Kenya. We donate the sales from our woodcrafts to the program and have raised $71,000 to date. It has funded construction of classrooms, a 12-computer technology lab, a lunch program, school organic gardens, tree seedling nurseries, a bicycle transportation program and women’s health workshops. As we are now home all day, every day, we have been spending extra time on our crafts — my wife, Jean, knitting up a storm and me cutting a lot of wood. Most of our fund-raising for Grow Against Poverty is at our annual holiday sale in November and December. I’m working on projects for this event. My Peace Trains have been especially popular with grandparents. I’ve also been turning 12-in. Baltic birch plywood platters and maple salad bowls, then finishing them with dye or food-safe coloring. – John and Jean Roccanova

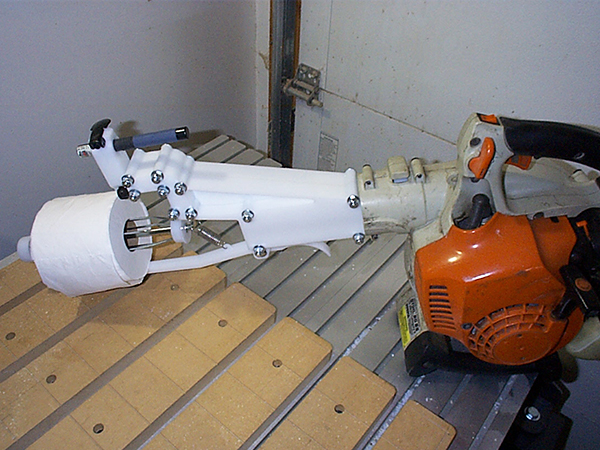

I have been wanting to challenge myself with some unique CNC machining opportunities during this time. This is a whimsical project I’ve been considering for a few years, and it seemed like a good time to try it. The challenge is to make a high-velocity, laser-guided toilet paper dispenser from a leaf blower, a laser pointer, a paint roller, and a roll of toilet paper. It is important to note that no toilet paper has been actually used for this project … yet. I’m waiting for the toilet paper shortage to end before extensive testing can commence in my neighborhood. Also this dispenser is not designed to launch the whole roll at once. Instead, it’s designed to unwind the paper rapidly. This is similar to how a spinning reel works for fishing. All parts were made from HDPE plastic. This dispenser is actually capable of distributing two full rolls at the same time. I hope the potential for this project is appreciated. – Bob Hartig

Here are a couple of pics of recent projects in response to your Weekly request. First, an alder bookcase with through tenons and a ship-lapped back. Second, a walnut serving board — one of nine I’ve made. It has epoxy fill and copper plugs. – John Baker

I’m in the process of finally building a home for all of my hand tools. My tool chest is a cross between Chris Schwarz’s tool chest and a crate style show box we had for the county fair when I was a kid. The front and back were glued and brad-nailed in temporarily, then the sides were pocket holed in. In order to be able to take advantage of some scrap material, the sides and back aren’t glued up as panels but left as independent. The whole thing will get milk-painted soon. Right now, I’m busy making up a saw till and trays. – Ethan R. Chitty

The birth of a grandson motivated me to start woodworking about two years ago. I’m working sporadically on several projects in my half of the garage shop area. Attached are a couple yet-to-be finished projects that have sat dormant for months that are now getting my attention as the virus pandemic invades our lives. – Doug Fishback

A little over a year ago, my wife wanted to remodel the house in an aged/weathered barn wood look. I only had a bunch of various scraps of different species, not enough of one type to make a complete project. With it I was able to make a TV stand using oak, maple, poplar, cherry, hickory and a couple others I couldn’t identify. Since that time I have made a matching side table and am currently in the home stretch of finishing a matching coffee table. This quarantine has been a blessing for me to spend so much time in the shop. And my wife actually appreciates it too, because now I have the time to make all the projects she’s been hounding me about for a while! Win, win, right? – Scott Williams

I’m 70 years young and just beat throat cancer. That said, I am really vulnerable to the corona virus. As such, my wife has me on “couch arrest” and only allows me out of the house on “work release” to work in my wood shop. Not being a pro-woodworker, I still enjoy building small projects. I just finished a pine cradle for my soon-to-arrive great-granddaughter. A dowel with a wooden knob acts as a locking pin that, when removed, allows the cradle to swing. I really enjoy your magazine and online Weekly. Keep up the good work. – Tommy Thomason

My time has been consumed helping lead our health system efforts in response to COVID-19. Any get-away time is to my shop, when possible. I needed to consider a project that wasn’t too time-consuming but meaningful for my brother’s upcoming birthday. My brother is the epitome of the man who has everything. So what could I consider giving him for his 70th birthday? I went to the shop, milled some walnut and edge-glued the sapwood into the center to create the illusion of a ray of light cascading over the piece. After routing the edges, it was off to the laser to engrave our family crest to complete the plaque. Pairing it with a stand was the final touch. He was quite appreciative of this personal memento. – Jeffry M. Tillery, M.D.

I’ve been working on a Morris chair, a cabinet and some deck chairs. Trying to keep busy. – Larry Flick

Here’s a daybed/porch swing I’m working on. – Richard Hurst

When I went to buy a dining room table and couldn’t find one the right size, I decided to build one that better fit my needs. I was also able to build a matching side table. – Debbie Shipman

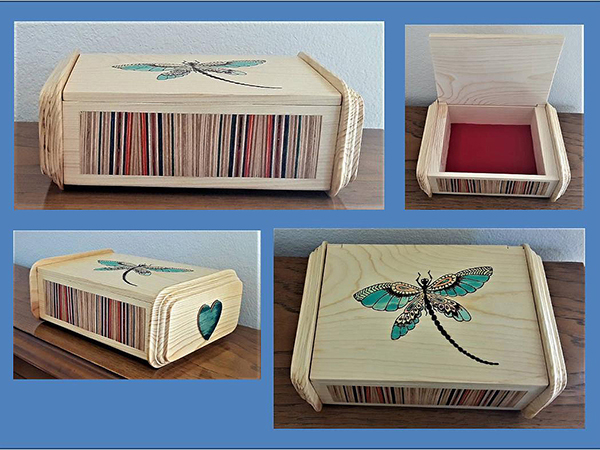

My grandson is a professional skateboarder and donates his old skateboards for my various creative projects. The latest project was a simple jewelry box with skateboard inlays and a pyrography-and-watercolor dragonfly lid. – Michael E. Riffel

I needed a table to assemble projects on in my shop, but I didn’t want to sacrifice the floor space. I was inspired to build this “Murphy” table after seeing a similar setup in my veterinarian’s office. When not in use, it folds up against the wall and out of the way. As a bonus, it can serve as an outfeed table for my table saw. – Jack Thomas

I own a company that makes tools and repair equipment for bicycles. We make repair stands to hold bikes off the ground while they’re worked on. I made this cradle for my first grandchild out of quartersawn oak then used Danish oil to finish it. No plan, just started building and penciling like I usually do. I installed some flanged bearings on each end so it rocks (like a dream) with the Park Tool repair stand parts serving as the uprights and base. The legs fold for storage, and the cradle detaches easily for storage in between users. My granddaughter was born at end of February and uses the cradle every day at my daughter’s house. This will pass from one grandchild to the next as needed, and I hope to write their names on the bottom for posterity. – Eric Hawkins

I built a patio-style double back door last out of white oak recently, and it had no covering over the glass. So I’ve just made mini shutters for them — 160 blades divided like the glass sections. They’re neat and low-profile and work great for my purposes. And I think they look good too. The sun shines through them with warm light. – Frank Clements

Forty years ago I built yachts for a few years and worked with some old-time boat builders who could do some amazing things with very basic tools. I have always wanted to build a boat for myself, and since I am 71 years old, I figured it was now or never. This is a 12-foot skiff from a design by Spira International. I can’t begin to tell you how much I’m enjoying building it. – Wade Colclough

I started this vinyl record table before the outbreak, but I was working on it intermittently. Having all this time at home motivated me to get into gear and finish it. I wanted the records to be displayed facing out instead of from the side like most storage units. I find it more inviting, since it encourages you to thumb through the records. It’s solid maple for the table with cherry for the drawers. Full dovetail joints on all four sides, just for fun. I used Blum undermount drawer slides from Rockler to give it a nice, clean look. The maple is a mishmash of heartwood, sapwood, some curly even some spalting in places. I like the randomness in it. My father-in-law recently moved to a retirement home and gave us a bunch of old, old records (some are even the old shellac 78s). Now we’ve got a place (and some time) to listen to them. – Christian M. Restifo

Lately I’ve been scroll-sawing in my shop and social distancing. Love the extra time I now have. – David Lutton

I have a close family friend who is in high school and was unable to fit wood shop class into his schedule. He asked me if we could build a chess board — it’s the shop class’s first project, as the design provides introduction to lots of tools and techniques. So since school is out, we were able to complete the board over a week’s time. He was so excited to complete the board so quickly, which was all due to the one-on-one time we were able to spend on it. He chose wenge and ash for his contrasting woods. – John DeVries

Recently I was commissioned to build a work station. It’s solid maple, and the base is steel pipe and fittings I picked up from a big box store. I’m very pleased with the result, and my client was ecstatic. – Shawn Blythe

A new bird house a toy truck have kept me busy lately. – Richard Brownlee

Just wanted to share some pictures of my router table organizer cabinet that I built while maintaining my social distance (which wasn’t very difficult when you love to do woodworking and not be interrupted by anyone). My dad had helped me build my first router station over 30 years ago, and we were very proud of our accomplishments. But with the advancement of technology and new jigs and accessories available, I knew it was time to update my router station. This project was inspired by the Woodworker’s Journal YouTube video I came across while planning on updating my router station. I purchased the router table and accessories through Rockler (and just had to order more bit inserts). I am extremely happy with the customer service I received from Rockler, and their products are top-of-the-line. While completing this project, I was able to utilize various pieces of leftover wood that I had in my basement workshop, thus eliminating the need to go to a home center for supplies. Although my project is far from perfect and my skill level is mediocre, I am still proud of the way it turned out, and I am sure my dad is smiling down from above at me! Now, what to do with my old router table? For sentimental reasons, it will stay with me and possibly be turned into a storage unit. Thank you for all the great ideas and plans, and if this isolation goes on much longer, I will definitely be building more projects. Stay Safe! – Karen Payne

I’ve been working on a rustic log bench, a canoe paddle and some wooden rings. – Brad Adams

While my particular project has been finished for a while, it may inspire some stuck at home that are both woodworkers and home wine makers like myself. When I retired, my son bought me a basic wine-making equipment kit. I was hooked. Next thing I knew, my finished basement became overloaded with cardboard boxes filled with homemade wine. That (and my wife’s complaining) was the perfect excuse to build the storage wall shown in this photo. It’s a very simple design that uses a “ladder” construction of 1 x 2 legs with the bottles resting on 3/4″-square “rungs” and horizontal spreaders. I used Philipine mahogany for construction. I first had to remove the carpeting and install ceramic tile in order to provide a solid surface to support the weight of over 200 bottles of wine – Frank McMullin

I have thought about this project since before the stay-at home order came into effect. But since the pandemic has kept us inside, I decided to build my table saw outfeed/assembly table. Using three Rockler T-tracks inset in the top and Rockler Bench Cookies to elevate and grip projects will work perfectly. Adding a bench vise will be essential. Keep safe all. – Bryan Schmidt

Last Christmas I made a band saw reindeer for the first time. My wife said she wanted a whole herd, so now seems like a good time to get working on it. I’ve been occasionally throwing in some other band-sawn animals for fun, like the pelican and roosters (as well as a failed attempt at a dog), and I plan to try some more new ones soon. – Andy Drozinski

Two years ago I remodeled my kitchen. I made all the cabinets and raised-panel doors, added LED lighting and so forth. I worked on the kitchen remodel and cabinets for approximately six months, every night after work and every weekend. The project burned me out and I couldn’t get motivated to finish the top. Last week I finally got motivated after two years of stalling (“planning” … ha!). I installed the top in the kitchen and thought it turned out great. But the first comment from my bride: “It doesn’t match the rest of the kitchen.” I can’t win… I should have just put a piece of oak plywood on and I could have finished the project in an hour… but that’s no fun! – Dave Walsh

This is an end table for our living room. I came down with polymyalgia rheumatica in January and have not been able to work till three weeks ago. I may have only worked an hour or so a day on this end table, but I am proud of getting it done. I hope to get it stained and finished by the first weekend in April. – cpknudsen

I hate to discard or burn those lovely scraps of hardwoods left over from projects. They accumulate in a bin in the shop, and lately I have found ways to use them. These are a few of the small projects I am making now. Friends enjoy my tissue box covers, and the salmon serving board was a gift for a fisherman friend. Spending time in the wood shop is a good way to pass my social distancing time. – Joyce Pearson

Here are a couple of my box projects during the shutdown. – Connie Wendinger

Early in our “social distancing” time, my wife saw plans for a garden obelisk in one of her magazines and decided she could use a pair for some vines in her flower gardens. I modified the plan a bit (we do that?) and built them out of wood left over from other projects. When we ever get through with our wet weather, she’ll paint them to match our pergolas. – Tom Baxter

I just finished a kitchen cabinet for my grandson. I am now building an in-wall cabinet for my daughter’s bathroom. I am also in the middle of building a nice bar for a co-worker’s garage. – Lou Toutant

When I needed a new stove for my small maple syrup production of 100 taps, I decided to build a sugar shack in my back yard of 5 acres to hold the stove. A number of years ago I had hired a local man with a team of horses to come to my plot of forest and harvest the maturing evergreen trees. They had been falling down faster than I could cut them up to keep open my trails. He did a fine job and gave me a choice of rough-sawn lumber as payment for the logs. I chose enough 2x4s to build a shed. It was these that I used to help build the shed. I had to build a vent in the high end of the roof to allow the steam a place to escape. An old piece of a garage door made the door to this vent. Works very well. The shed will also be used for off-season storage of the equipment used to make syrup, so I had to make it vermin proof. I sat out there last week with the rain pattering on the steel roof, smoke curling up from the chimney, sap boiling in the pan and the steam venting out the opening. Even my dog, Pepper, says it is more comfortable to make maple syrup now. – Bill Gunn

My grandkids live a few states away so we don’t get to see them as often as we would like. I wanted to give them something to smile about during their time at home, so I texted them and told them my shop was being invaded by Christmas critters. After a few minutes of questioning texts frome them, I sent some photos of these reindeer I’ve been making. That sparked a flurry of great texts back and forth for several minutes. I’ll keep them updated as the project continues for the next few weeks. Hopefully we can get back to normal before I’m done with my project. – Ernie Stutz

I live in the country on 27 acres and love to target practice. Over the years I have bought numerous large targets (24 x 40 in.), which are now rolled up in several bundles. That makes it hard to access the target that I want. So I decided to make a large cabinet with six drawers, each with inside dimensions large enough to hold the targets flat. Since the cabinet was going to be quite large, I decided to incorporate the cabinet as an additional outfeed table for my table saw. I mounted Rockler workbench casters and quick-release caster plates so that I could move the cabinet when necessary. I have all the drawer parts made and am now waiting for a nice day to sand everything outside before assembly and finishing. – Bob Stuckey

Coupling social distancing with a recently remodeled master bath that still needed some accessories to finish it off pushed my truck and my wife’s car out of the garage and woodworking equipment rolled out to the ready. We needed a couple clothes valets, a trash can and an over-the-toilet wall cabinet. These accessories will be painted to match the new vanities, so mixing wood species within a project wasn’t a concern for me. I may risk a trip to get paint that matches the vanities as I’d like to paint the panels before assembly to preclude unpainted shrinkage lines. Crown trim will probably be added later when shopping is an option again. I’m an amateur woodworker approaching 70 and owe lots of gratitude to Marc Adams School of Woodworking which has enabled the skills that keep me so entertained. – Roger Tyler

Here’s a cabinet I made using old shutters for doors. This cabinet was made for our daughter’s master bathroom. I drew up the plans myself. I used pine as the wood and 1/4-in. plywood on the back. – Jeffrey Hoover

This may not be exactly what you had in mind when you asked for “projects,” but I baked this dessert this morning. It’s a nice lemon cake with lemon frosting and made with pudding in the mix. I’ll be sure to think of you while I am enjoying my second or third piece on my upcoming birthday. – Robert Hoyle

My latest project is a Byzantine-era portable sundial and geared calendar. – Michael D Giltzow

Recently I’ve been expanding my small basement shop. Happily, I had all my materials and supplies in advance so that I could complete “Phase 2” of my basement shop while being “safe at home.” This phase of the project included studding out, insulating, sheet rocking and painting the walls, then installing shelves, power and LED lighting. I moved in several filing cabinets for parts and material storage, built a small bench with a drawer and a small shelf for my battery-powered tools, batteries, and a charging station. The crowing jewel is my 55-lb. antique stand vise. So far, the expansion has turned out great! My basement shop will be complete with “Phase 3” of the project. This will include more studded, insulated and sheet-rocked walls, a utility sink with drain and a closet (for more storage) for my den. – Mark Smith

Lately I’ve been making crosses and repairing a chair. – John Stephens

Over the past 2 to 2 1/2 years, I’ve turned 120 or 130 bowls, boxes, plates, grinders, spindles and other objects in various tropical woods such as mahogany, tamarind, tibit, mango, red mangrove, seaside maho, neem and banyan — all local woods to me here in the U.S. Virgin Islands where I live. My wife, Debbie, wanted a plate or two for cheeses and/or fruit, etc., for small groups when entertaining, with a wide foot so it wouldn’t be unstable when using a cheese knife to cut near the plate edge. The current COVID issue makes messing-around-time plentiful. – David Kummerle

In response to your question, I’m building a blanket chest and seat from plans in a book by Franklin H. Gottshall. I’m lining it with cedar I’ve milled from some trees cut down by the local electric cooperative. – Ron Schiaffo

I’m building a walkway up a mountain on my 0-scale train display. I have been inspired by my walks at the local metro parks where I often walk, so I’m including a photo of my grandson, my dog and myself at the park. I am still working on the train display. – Ernie Richmann

I recently built this hickory table for my friend. I’ve also been tired of the same old thing when it comes to turning bowls, so this is what I came up with. I think they are pretty cool. I’m staying busy and I love what I do. – Maryann Veentjer

My project — a combination display case and coffee table — is obviously still in the building phase. It will display a scale replica of the old Tiger Stadium in Detroit. The stadium was torn down after the 1999 season. While I have neither the patience nor the talent to build such a detailed model, its builder has created several models of old Major League ballparks; most are displayed in museums. This one was donated to a mutual friend who is an avid Tiger baseball fan. The next step of my display case will be to add all the doors and drawers that will enclose the entire lower level below the display case. Then comes staining, finishing and some electronics to light it up. – Ray Barons

My project this winter is a roll-top desk. Looking for plans online, I was disappointed in that so many are “simplified” in their design. Lots of them use plywood and screws, which I did not like. These factors drove me to do my own desk design. I took pictures of what I liked and sketched the size of desk I wanted. Being a hands-on person, I did not want to spend hours drawing paper plans for details, so I decided to build the desk from the inside out. I wanted wood that is not expensive and pretty stable, so I chose red oak. I started with the drawers. I had fun resawing the drawer sides and doing the dovetails. Along the way, I’ve learned many things, including the fact that building and installing tambour is tricky! It would be easier if the top was a separate piece, and two pieces would be lighter to move. I’ve made a few mistakes too, but I’m not telling where. Figuring how to do the next step is fun for me. That’s what woodworking is all about! And yes, there will be a hidden compartment. Got to get this desk done before the grass starts to grow! – Bob Zeliff

Here is the first of four chairs that I am making during the Covid crisis. Based on Gerrit Rietveld “crate chair” design with a sports (oh how I miss them) theme. The logo, numbers and player name have been scrolled-sawed out like a jigsaw puzzle, painted and then reassembled back into panels. Then the whole chair was sealed with spar urethane as it is meant to be an outdoor chair. Was not planning this, but I found myself with a bit of time over the last couple of weeks. – Matthew Jungblut

I have spent my shop time using a dwindling wood supply to try some new techniques on my lathe. I’ve made a pine bowl, two “pop top” boxes of walnut with a contrasting knob on top and a twig vase made of basswood. All are finished with multiple coats of Waterloo. – Glenn Deuchler

I have spent my shop time using a dwindling wood supply to try some new techniques on my lathe. I’ve made a pine bowl, two “pop top” boxes of walnut with a contrasting knob on top and a twig vase made of basswood. All are finished with multiple coats of Waterloo. – Glenn Deuchler

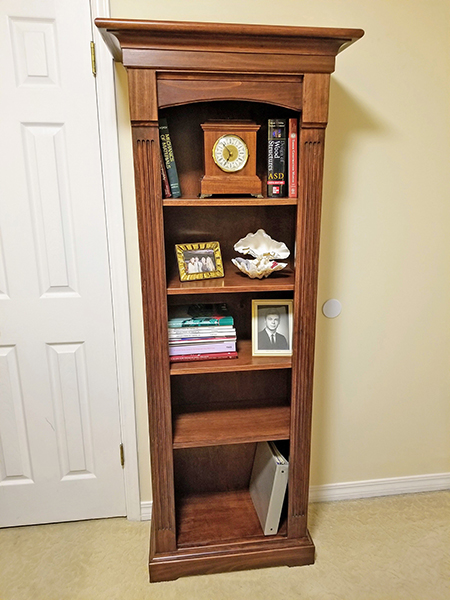

Recently I completed a tall narrow bookcase for my technical books and miscellaneous memorabilia that were lying around my home office. It’s constructed of poplar with a walnut stain. – Gil Jennings

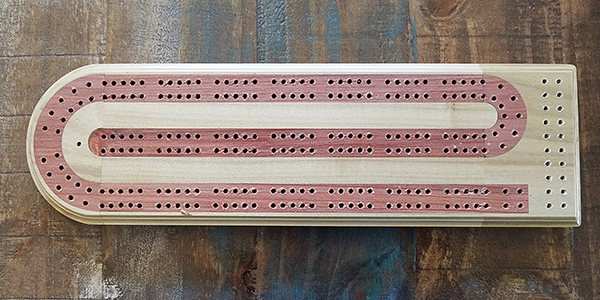

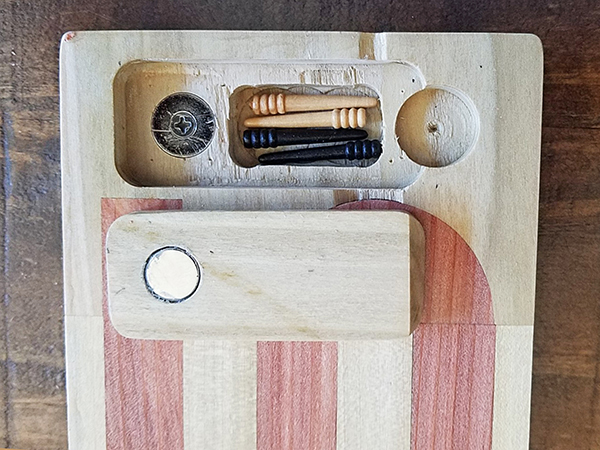

My wife and I learned to play cribbage not long ago, but the board we had was a small 2 player travel size, 60 holes. So while social distancing, I built this one using Rockler’s Small Cribbage Board Templates (item #53651; Two-Player, Curved Track). The board is made from poplar and red wood because I didn’t have any other hardwoods available. I added pin storage on the back using a rare earth magnet to hold the lid on. – John Zabel

I’ve spent the last year repurposing the back end of my large shed. I turned it into my new woodworking shop. So, what to build for my first project in the new shop? Easy answer: Christmas presents for my two kids. I’ve been a home beer brewer since the early 90’s and taught both my kids how to brew a fine ale. I suggested that I build them a pair of beer paddles. If you’ve been to a craft brewery and ordered a flight of beers, you probably selected four beers from the menu and they were delivered in small glasses on a wooden beer paddle. My kids each selected the glasses from a favorite brewery and gave me the freedom to design/build their paddle. I really enjoyed all steps in the design/build process. Best of all, I got to use all of my new woodworking equipment and expanded my skills by doing my first inlay work. The paddles pictured here were completed for my son. – Brian Kise

Here are a couple of end tables I’m building. The handles are not completed yet, but hopefully next week! I’m waiting on a block of ebony! My daughter requested a similar set of tables for her birthday/Christmas presents a few years ago. When I finished those, my wife almost demanded that I make a set for our house. I do not like to duplicate things, so I modified the design and added another two curved surfaces (front left to right and front top to bottom) to the original set that had leg curves on the side. I used solid sides as opposed to stile and panel in the original set. These are made of cherry with mortise-and-tenon joints and sliding dovetails to fasten the solid cherry top to the sides. – Duane Sellers

About a year ago I made a coffee table for our cottage along Lake Erie. The cottage was sold and our grandson inherited the coffee table as he set up his first post-college apartment. Now, of course, he needs end tables to go with it. I had enough lumber left, so that has occupied me while staying at home practicing social distancing. It’s fun to make a second of a one-of-a-kind project — seems to go better the second time around. The tables are ash, with walnut details. Lots of fun for a retired architect. – Lynn App

Here’s some patio furniture I just completed. It’s fun to sit outside and greet neighbors and others who walk by in the street. – Daniel Jerzak

My brother-in-law, who pastors a small church, needed a desk to hold the sound system, CDs and Sunday school literature. So with the extra time at home, I took on the challenge. This desk (first photo) replaces the previous arrangement (second photo) that was inadequate and too handy for little people to access! I just have the drawers to finish. I think that he will be very pleased with the finished product – Marcus Hartley

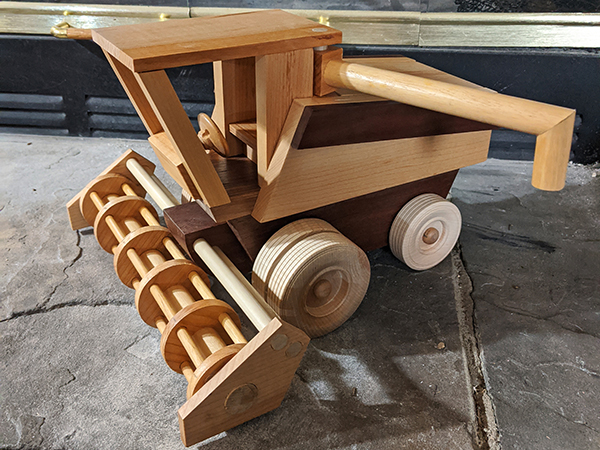

Every year I make something for my grandkids. Otto lives on a farm and loves the combine — or as he calls it a “bombine.” This year I made him a miniature bombine out of wood. – Paul Vanslambrouck

Here is my oval shaker box with an inlaid piece of marquetry. I made a smaller box that fits inside with a heart that I left proud so one could feel the heart with their fingers. Numerous different woods were used for this project — most that were ordered from Rockler of course! Be safe out and about! – Claudia Fletcher