Most of the cutting edges we use for woodworking are meant to be kept, re-sharpened and used for many years. Still, there are times when the convenience of a sharp, inexpensive and disposable blade can be very handy too: cutting carpet, breaking down cardboard boxes or slicing batts of insulation, to name just a few instances. That’s where utility knives with razor blades make perfect sense. And while they are ubiquitous to modern life, at some point in history they were inventions that revolutionized the process of cutting ordinary materials. From then on, utility knives have made life easier.

The next time you’re eating a segmented chocolate bar, here’s a curiosity of history to remember about utility knives — particularly those with segmented blades. For Mr. Yoshio Okada, that same confectionary treat served as the inspiration for developing the world’s first snap-off blade cutter. It all began when Okada received a chocolate bar as a boy from an American soldier during WWII. Its breakaway chunks intrigued him.

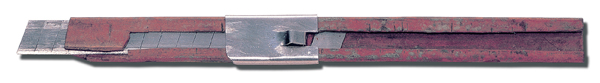

Fast-forward to the early 1950s, when Okada was working for a printing company as a young man. Workers at the time cut paper in the factory with knives that dulled quickly, or razor blades that they then threw away. Okada considered the practice wasteful. He recalled that Japanese craftsmen had once cut paper with the sharp edges of glass instead. Could a blade be developed that would combine the razor-sharp but brittle edges of glass with the breakaway properties of a chocolate bar? Okada thought it could be done.

“After much trial and error determining the best blade size, angle for snapping and so forth,” says Matt McDonnell, director of brand marketing for OLFA at WorldKitchen, “Okada developed the first snap-off blade cutter in 1956.”

Soon thereafter, Okada went on to found the OLFA Corporation, which is headquartered in Osaka, Japan. He also patented the break-off blade design. He decided to call his company OLHA, which in Japanese means “breaking a blade.” (An “F” soon replaced the “H” so that the consonant wouldn’t be lost by some other languages that don’t pronounce the “H” sound.)

Since then, McDonnell says, the length, width and angle of the blade, as established by Okada, have become the worldwide design standard for snap-off steel utility blades.

Building on Okada’s original design, OLFA pursued a “seemingly endless refinement” of its blade steel chemistry and sharpening methods to produce blades that would break off easily when needed to expose a fresh, sharp edge, while also being strong enough for tough jobs, McDonnell says.

Improvements and refinements to blade technology continue at OLFA today. Using only the finest quality of steel, “we adjust hardness, sharpening angles, tapered dimensions, the coarseness of the whetstone, grinding speeds and so forth, for every (blade) type, to ensure the blade has the best balance of high sharpness and long life.”

Presently, OLFA manufactures more than 50 different models of snap-off blade knives, plus a diverse line of other cutting tools that number more than 200 products in all. WorldKitchen is the exclusive distributor of OLFA products in the United States and Canada.

Okada’s original snap-off blade patent was only valid in Japan, so OLFA’s success in selling low-cost, easy-to-use utility knives has prompted other companies to duplicate the blade design for their own knife styles. But McDonnell says OLFA branded knives are still a “cut above” the competition in terms of quality.

“An astounding 46 OLFA products have been awarded a ‘Good Design Award,’ which is granted by the Japan Industrial Design Promotion Organization as proof that the awarded product has remarkable quality in both aspects of design and practical use.”

Thirty-three more OLFA products bear the “GS mark” for approved safety, McDonnell adds. That designation means the product is certified by German product safety laws — a significant distinction.

DIYers, McDonnell says, appreciate OLFA’s 18mm snap-off blades and handles. They’re designed for a wide variety of applications and are engineered for cutting all types of materials. He says the Pistol-Grip Ratchet Lock Utility Knife (Model L-1) is the “workhorse” of this category, and the Comfort Grip Utility Knife (Model LA-X) offers an anti-slip handle with an ultra-sharp black blade and a built-in hard-metal pick.

“The OLFA Ultra-Sharp black snap-off blades have a 25 percent sharper edge than the silver blades, for greater initial sharpness and less cutting resistance.”

Extra Heavy Duty Cutters, with wider 25mm blades are impressive, McDonnell assures. Equipped with solidly built handles and nonslip cushion grips, he says the knives in this category (Models H-1, NH-1, XH-1 and XH-AL) can stand up to the toughest jobs. These are the knives which accept the blades OLFA manufactures specifically for cutting wood, such as the 25mm Japanese carbon steel blade with 59-degree edge angle, and its wide and narrow saw blades. The wide blade was designed primarily for working wood.

Two other innovative tools from OLFA are also worth consideration. The company makes Serrated Edge Scissors (Models SCS-1 and SCS-2). The stainless steel blades are sharpened to the tip, and one of the two blades is serrated, which helps prevent slippage when cutting thicker, difficult materials. The handles are designed for right- or left-handed use and made of lightweight but tough ABS plastic.

Okada’s inventive spirit also extended to the world of textile cutting. In 1979, he invented the OLFA Rotary Cutter, which functions like a rolling razor blade. The circular blade design allows for cutting multiple layers of fabric without distorting the material. McDonnell says the Rotary Cutter revolutionized the quilting world, where “straight lines and quick, accurate cuts are crucial to the construction of these intricate and detailed quilts.”

And, motivated by Okada’s inspiration nearly 60 years ago, OLFA continues to provide unique cutting solutions. This fall, McDonnell reveals, OLFA will launch two new 18mm blades: one is designed to cut a variety of insulation materials, and the other, called the Speed Blade, will cut more quickly by reducing friction.

OLFA products are sold through a number of home improvement and crafting retails as well as online. To learn more about the company history and OLFA’s full line of cutting tools, click here.