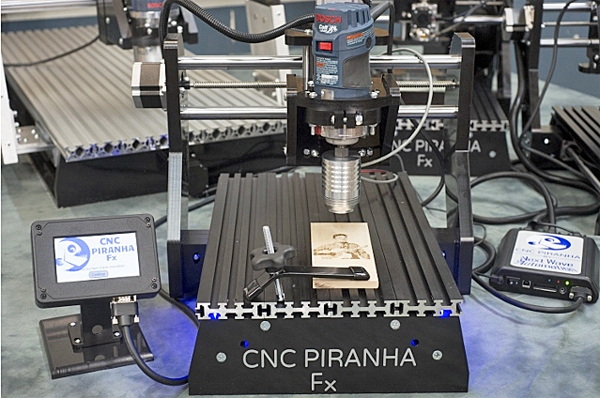

Last fall, Tim Owens, founder and CEO of Next Wave Automation, launched CNC Piranha — the smallest machine in its growing line of CNC solutions for small-shop woodworkers. Next Wave also produces several iterations of the popular CNC Shark machines, as well as Ready2Rout and Ready2Lift automated router table products.

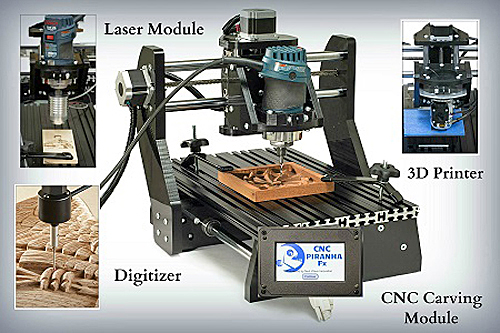

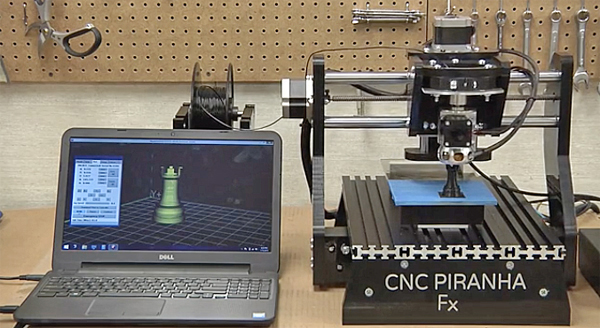

Soon, there will be a new predator fish in the company’s “school” of options, thanks to a successful Kickstarter campaign that launched in mid-February and hit its financial goal ahead of schedule. It will be called Piranha Fx — a hybrid CNC machine geared toward woodworkers and makers of all sorts. It will be the first machine of its kind to deliver carving, laser engraving and 3D printing all from one benchtop sized unit.

“We like to keep things interesting and to push the advancement of the market,” Owens says of his Holland, Ohio-based company, which he founded eight years ago. “(Piranha Fx) is a product that’s in line with our philosophy at Next Wave: high quality, functional technology made in the USA at an affordable price.”

Unlike previous CNC models, which Owens developed and launched independent of investors, the new CNC Piranha Fx is coming to market with many financial backers already in place. Owens used Kickstarter to raise the startup funds and to test the waters for this new breed of CNC functionality.

“Technology moves so quickly, and we wanted to make sure we were creating the right mix in our Piranha Fx machine.”

Had the Kickstarter campaign failed by the end of March — its original deadline — Owens says Piranha Fx would have gone back to the drawing board for more development. The project would only move forward into production stages with Kickstarter backing.

Judging by the performance of the Kickstarter campaign, however, Owens has landed on a ready market: in just under two weeks, Piranha FX reached its $75,000 startup goal, thanks to backers who could pledge from $1 up to $2,899 — the wholly inclusive cost for the machine and all of its accessories. And, the Kickstarter campaign continues now. Those still interested in the attractive startup pricing can become Kickstarter investors until March 31. Doing so, Owens says, will enable them to receive Piranha Fx about 60 days after the campaign ends versus later in 2015.

The inspiration for Piranha Fx came more than a year ago, when Next Wave began its initial research and development process. Owens says that while other CNC machine competitors are building single-function laser engravers, 3D printers and CNC carvers, none offer much in terms of compatibility and functionality.

“Since we had already developed the extremely robust CNC Piranha for woodworkers, it just seemed logical to expand the Piranha’s functionality in a way that made it more sophisticated and capable as well as affordable. I also wanted to make an ‘all-in-one’ machine for inventors and schools that had the same interface and footprint and that was lower in cost than most machines out there.”

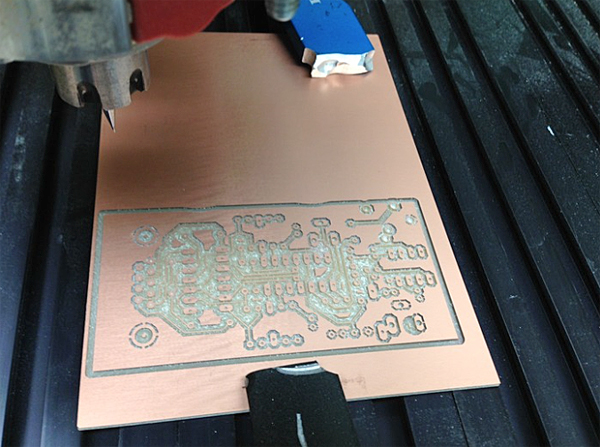

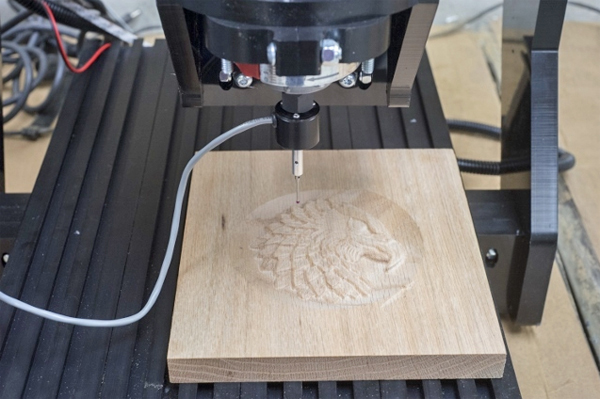

The foundation of CNC Piranha Fx is its CNC routing module. It features a 12 x 13 x 3-in. working table area and comes with a Bosch Colt router. As with other Next Wave CNC models, users can create original projects using the included Vectric software or import other existing CAD designs. A touchscreen interface is provided to program the machine’s run features. The routing module enables carving in wood, aluminum or other soft metals and plastic.

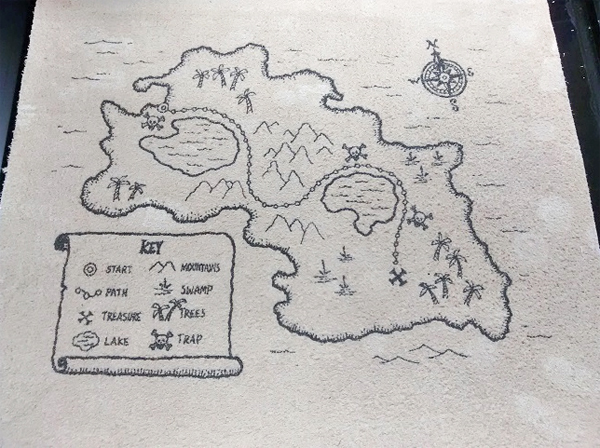

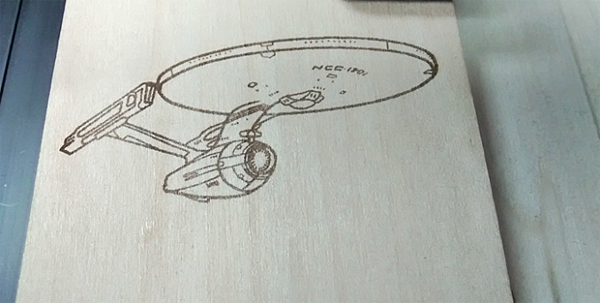

Owens says it only takes about a minute to switch from Piranha Fx’s carving module to the laser engraver. The full variable 3-watt laser will engrave flat surfaces such as paper, wood, plastic, leather or fabric. A raster function allows you to engrave existing photos, or you can design new images using the Vectric software. While you can control the power level of the laser for shading and depth-of-cut purposes, it will only cut through very thin material. It is not suited for metal-cutting.

Or, to 3D print — which in lay parlance amounts to “building” an object with a continuous filament of hot plastic — the end user need only bolt on a separate plate for the printing module.

The 3D printer functions similar to a hot glue gun, Owens explains, but instead of a trigger, the printer’s motor precisely dispenses plastic thread from a spool of filament that resembles weed trimmer cable. Piranha Fx can create small objects all the way up to those with a volume build area of 430 cubic inches, and the plastic filament is readily available.

An optional digitizer will make the replication process easier. It chucks into the router and enables Piranha Fx to touch an existing object in order to “learn” its three-dimensional attributes, which it can then replicate by way of the 3D printer or carve using the router module. The digitizer will make it possible to duplicate hard-to-find objects easily, or to mass-produce copies of a handmade original.

Kickstarter pricing for Piranha Fx is tiered. Those backing the product at the $2,899 level receive all three modules plus the digitizer. A pledge of $2,699 or more buys everything but the digitizer. For those wanting just carving and laser engraving capability, there’s a pledge level of $1,999, too. Package specifics and estimated delivery dates are detailed on the Kickstarter web page.

Next Wave hasn’t yet determined what the “street” price of Piranha Fx will be, once the product goes into full production and is available to non-Kickstarter buyers, but, Owens says the cost will increase after the Kickstarter campaign concludes.

Rockler, a major supplier of Next Wave’s CNC Shark and other products, has expressed interest in carrying Piranha Fx in the future. Piranha Fx will also be available for purchase through Next Wave’s website. Current CNC Shark owners should stay tuned, Owens teases: the laser and 3D print accessories are going to make their way to the CNC Shark line as well.

“Reaching our (Kickstarter) goal in well under the time allotted tells us that there is a huge level of interest and significant demand — from woodworkers and others — for a ‘maker’ type of machine that utilizes all kinds of materials for all types of projects … I’m happy to say we’ve achieved all of that in the new Piranha Fx.”

Learn more about Next Wave Automation and its products by clicking here.