I have an old house in Nova Scotia that must have been built by shipwrights. The framing is finished with an adze and the various shelves and cupboards supported by ship’s knees. These are L-shaped wooden brackets where the curve of the grain roughly matches the shape of the knee. They are an elegant alternative to the usual storebought steel knees and traditionally were used to connect the various parts of a boat. With the decline in wooden boatbuilding, such knees are no longer obtainable. So if you want a set, you will have to make your own.

Many people — and I’m one of them — thought the only way to make wood knees was to cut a number of thin strips, glue them up in a form and finish the glue-up mess by hand or machine. Such knees are amply strong, but a time-consuming nuisance to make.

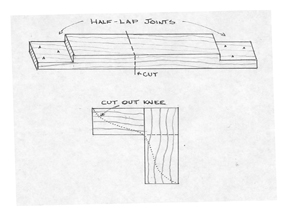

The Cornish boatbuilder, Ralph Bird, showed me a much better way. His trick is to use the table saw to make a halved joint in each end of a piece of hardwood, preferable white oak. If the angle required by the knee is more or less 90 degrees he cuts the lap joints accordingly. After cutting the piece in half, so the legs are unequal lengths, he drives three brads into one surface and cuts the heads off close. The projecting points stop the pieces sliding around when applying clamping pressure.

The Cornish boatbuilder, Ralph Bird, showed me a much better way. His trick is to use the table saw to make a halved joint in each end of a piece of hardwood, preferable white oak. If the angle required by the knee is more or less 90 degrees he cuts the lap joints accordingly. After cutting the piece in half, so the legs are unequal lengths, he drives three brads into one surface and cuts the heads off close. The projecting points stop the pieces sliding around when applying clamping pressure.

After gluing the lapped joints together he cuts out the shape of the knee with a jigsaw and finishes them with spokeshave and block plane. Ralph needs a total of 32 knees for each of the Cornish gigs he builds, so clamps a bunch up together with wax paper between to prevent them sticking to each other.

Any more talk of boats and Rob will cut me off, so until next time….