Have you ever tried to chuck a triangular blank, cross drill a small hole off-center in a hardwood dowel, or keep a drill bit from wobbling while drilling in the lathe? The day-to-day work of machinists involves several tools useful to almost any woodworker.

Center Drill

To keep drill bits from wandering, a center drill works better than anything else I have tried. A center drill is also known as a combined drill and countersink or a Slocomb drill.

There are more than a dozen styles of center drills in 15 different sizes ranging from 1/8 to 1 inch. For woodworking, you don’t need anything more expensive than uncoated high-speed steel. The body diameter of your center drill should be the same as the largest drill you are going to use.

The Boring Head

A boring head is a more precise version of a circle cutter that can make a flat-bottomed hole of any size within its range. For the boring head shown, this is done by a dovetailed slide moved by a pair of set screws that push against the projection labeled “A” in the photo. Loosening one screw and tightening the opposite one moves the cutter to a larger or smaller radius. Always lock the dovetailed slide before making a cut. Any boring head needs a pilot hole. The range of the boring head shown is 3/8 to 1-1/4 inch. While most boring heads cost $100-$600, Taig Tools makes a good quality one (shown) that sells for $45 and includes two boring bars.

End Mills

Because drill bits are too long to resist much side thrust and cannot cut sideways with their flutes, they have a troublesome tendency to wander when not drilling a flat surface. You can remedy thi s by starting your hole with a center drill, but if the surface of what you are drilling is at too steep an angle to your bit, using a center-cutting end mill will work. Center-cutting end mills are ground for plunge as well as side cutting. Avoid end mills that are not center-cutting; they only cut sideways. End mills should only be used in a drill press or in the tailstock of your lathe because they will not start a hole if they are used in a portable drill.

s by starting your hole with a center drill, but if the surface of what you are drilling is at too steep an angle to your bit, using a center-cutting end mill will work. Center-cutting end mills are ground for plunge as well as side cutting. Avoid end mills that are not center-cutting; they only cut sideways. End mills should only be used in a drill press or in the tailstock of your lathe because they will not start a hole if they are used in a portable drill.

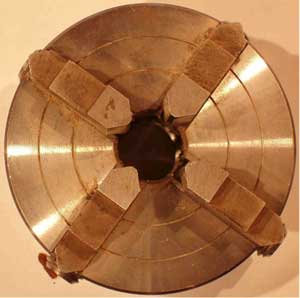

The Four-jaw Independent Chuck

Taig Tools makes a 3-1/4 inch chuck with four independently movable and reversible jaws, enabling you to hold blanks of any shape down to 1/8 inch diameter. Because each jaw moves separately, it can be difficult to center your blank in this chuck. To do this, set the tool-rest of your lathe at center height. Then rotate the chuck to bring one jaw level with the top of the tool-rest. Measure the distance between the jaw and the tool-rest, turn the chuck half a revolution, and measure again. Calculate half the difference between the two measurements and move the blank towards the larger measurement by that amount. When you have one pair of jaws running true, repeat with the other pair.

If you do not own a bench grinder, Taig Tools also sells a set of small grinding wheels that are useful for small sharpening jobs and an arbor to mount them on a lathe with a 3/4 inch 16 TPI spindle.

Lewis Hein is a machinist and woodworker who has been working with wood ever since he can remember. He lives near Casper, Wyoming.