About three years ago, Sirrus (formerly Bioformix, Inc.) unveiled two formulations of Nexabond adhesives. They were modified cyanoacrylate (CA) glues offering longer 3- to 5-minute open times than typical “super” glues and faster curing time than yellow PVA wood glues. Delivering full cure strength in around an hour, among a number of other appealing attributes, Nexabond was positioned as the next generation, all-purpose woodworking glue.

Then, just as the new brand seemed to be gathering momentum in the marketplace among a loyal following of Nexabond users, it disappeared from suppliers’ shelves. That has been causing some consternation among woodworkers. If you’ve been frustrated by the rather sudden absence of your newest favorite woodworking glue, take heart: its first cousin is closer than you think. What was Nexabond is now DAP RapidFuse Wood Adhesive. It launched in home improvement retail stores this spring.

“DAP has a heritage in adhesives as a manufacturer of contact cements, construction adhesives and other technologies that are used by many professionals. We recognized Nexabond as a really great adhesive created from unique and superior adhesive technology with huge potential to improve a wide variety of user experiences,” says Kate Piche, DAP’s group product director.

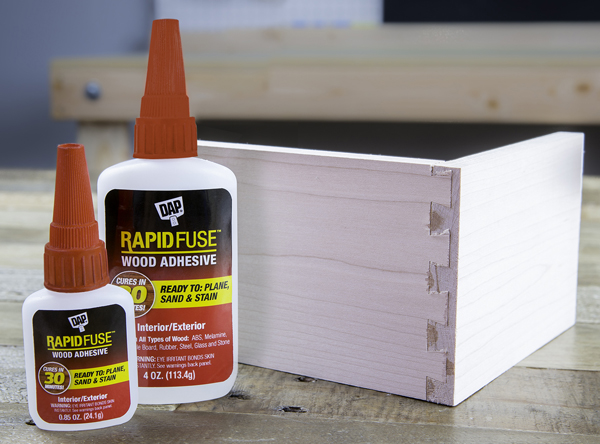

So DAP partnered with Sirrus and acquired the rights to manufacture and sell the adhesive technology that includes Nexabond. Their goal was to expand RapidFuse’s availability to a broader channel of retailers and to develop the adhesive technology of Nexabond into two options: a fast-curing wood adhesive and a multipurpose variety. What has resulted is DAP RapidFuse Wood and RapidFuse All Purpose.

“We’ve developed RapidFuse Wood to deliver the exact same performance as Nexabond … to back up DAP’s Satisfaction Guarantee to users,” Piche assures.

In case you didn’t buy Nexabond when it was available, there are some compelling reasons to give the new RapidFuse Wood a try. For one, it reaches full cure strength in a fraction of the time of yellow PVA glue.

“RapidFuse is the first fast-curing adhesive to provide the same level of strength and durability as a typical yellow water-resistant glue, and it works on all wood types,” Piche says. “It provides a clear advantage by reaching a full cure in 30 minutes … With RapidFuse it truly is only 30 minutes before your project can be lathed, planed, routed or sanded.”

One of the tradeoffs of typical CA glues is that overly quick cure times can compromise practical working time. That can be a challenge in situations where you want the ability to make fine adjustments to part alignment, such as when clamps are tightened down and parts shift. Brief working time is one of the reasons that CA glues are used less frequently than PVA glues, Piche says.

But, RapidFuse can trump CA glue’s working time: it offers about 3 minutes where parts can still be manipulated before the glue begins to set. And, there’s no need to panic once the glue is applied to wood but before workpieces are brought into contact with one another. RapidFuse can sit open for up to 40 minutes as a bead on the wood without curing. “It is when you put the two pieces of wood together that you transition to working time. RapidFuse Wood cures through substrate contact and will begin to cure with contact and pressure.”

If you’ve ever had a glue joint swell up, due to the water content in yellow glue, you’ll appreciate that RapidFuse contains no water or other solvents. Consequently, it won’t swell biscuits or dowels inside wood joints, and joints won’t shrink later when the water in water-based glues would otherwise evaporate.

Piche says RapidFuse is also a better value, in terms of the small amount of glue that’s actually needed to form a strong bond. Yellow PVA glue soaks into dry wood, so typically more glue is required to wet the surfaces. And, it should be applied to both parts of a joint, which produces squeeze-out and wasted glue. In contrast, a thinner seam of RapidFuse is better than a thick layer. Its gelled consistency doesn’t soak into the wood in the same way PVA does; the glue spreads out between the substrates on the surfaces of the joint to form a strong, thin bond. Only about half to one-third as much RapidFuse is needed, compared with yellow glue, Piche estimates.

“With this adhesive, less is more. You should avoid over-applying because too much glue can slow down your cure time.” Since RapidFuse will bond to skin, minimizing squeeze-out will also help you avoid gluing your fingers together.

One final point of note: ordinary super glues aren’t recommended for wet applications, but RapidFuse can be suitable for exterior projects. The adhesive is water-resistant and can stand up to occasional moisture. But, it isn’t waterproof and shouldn’t be used for projects that will be regularly soaked or submerged.

So, if you’ve been at a loss about where to find your next bottle of Nexabond, DAP’s RapidFuse can step in and take its place.

“(We’re) proud to bring this advancement in adhesive technology to woodworkers and DIYers because it is enabling them to get more done without making sacrifices on the performance and results of their work. We’ve spent a lot of time testing the performance of our adhesive with a variety of users and against a lot of competitive solutions so we can confidently say RapidFuse Wood provides a truly better solution.”

DAP is packaging RapidFuse Wood Adhesive in .85- and 4-ounce bottles, and you can learn more about it by clicking here.