Kreg Tool Company did not invent pocket-hole joinery. Chances are, that came not long after screws and drills were first paired with wood. All they did was make it so convenient, quick, foolproof, and affordable that “Kreg jig joinery” has become virtually synonymous with pocket joints. As one fan put it, “Kreg is to pocket holes what Kleenex® is to facial tissues.”

In simple terms, pocket-hole joinery involves drilling an angled hole into one piece of wood, then joining it to a second with self-tapping screws. The result is one of the strongest, fastest, easiest joints to make. It is also amazingly versatile, and works for case construction, face frames, picture frames, table aprons, leg assemblies, decks, windows, edge joinery, angled construction and even curved, segmented forms. Not surprisingly, the furniture industry has used it extensively since the early 1980’s, but it took Kreg to bring it out of the factories and deliver it into the eager hands of small shop and hobby woodworkers.

It all started when two unconnected events launched what became a revolution in woodworking convenience. Craig Sommerfeld, a tool and die maker by trade and a woodworker by necessity, was making kitchen cabinets for a log home he was building when his natural instinct for making things more convenient led him to design a jig for drilling pocket holes. Other woodworkers who saw it were impressed, and his family took to calling it “Craig’s jig.”

Sommerfeld lost his job in 1989 when the company he worked for closed their plant and moved overseas. With time on his hands, he started taking his invention around to trade and woodworking shows and selling it. At that time, it was a new concept, so not only was he introducing a clever tool to do the job, he was also introducing hobby and small shop woodworkers to pocket joinery. The first jig, made of aluminum, sold for about $100. It was fast and easy to use, so it caught on. Sales grew, and “Craig’s jig” became the Kreg jig.

Today, Kreg occupies a 75,000 square foot building, employs some 65 people and makes about 180 different items grouped into 20 main products. Craig’s son, Todd, is the general manager, overseeing the production and sales of a range of pocket-hole tools, pocket-hole machines and a relatively new line of precision measuring tools, fences, tracks, and guides. The company’s web site is delightfully easy to navigate, and is chock-full of helpful information. They still sell at woodworking shows, and direct from the web site, but now the majority of sales are through their dealer network, which includes not only the major woodworking specialty stores, such as Rockler Woodworking and Hardware, but also retail giants like Lowe’s® and Menards®.

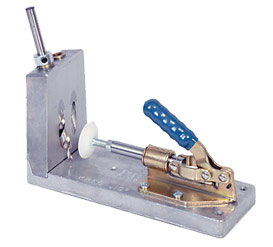

Their pocket-hole tools, the simple items that started it all, let a woodworker make pocket holes with his or her own drill. A variety of guides and clamps combine to make different variations of the tool.

“The Kreg Jig K2000 Pro Pack, for example, is the most popular seller,” Todd Sommerfeld told me. “It incorporates the single-, double-, and triple-hole drill guides, a step drill bit, a face clamp, self-taping pocket-hole screws, and driver bits. The combination gives you the most features and the most flexibility in one system, and at a cost that is substantially lower than if you bought each item separately.”

In 2003, Kreg acquired Mark Duginske’s Fast Track system, which had already blazed its own fine reputation among woodworkers. Their newly revised “precision measuring kit” includes a simple yet extremely accurate miter gauge, a band saw fence and a stop block system for chop saws, radial arm saws, drill presses and other stationary machinery.

New on the horizon is the K3 Jig, which is expected to hit the market in early August. It offers complete vertical adjustability for working with different thickness materials, a drill guide block that switches between the bench base and a portable base, a precision material support stop for multiples that swings out of the way without losing its set and a three-hole design that offers multiple drilling options. The clamping mechanism has been conveniently repositioned to the user side, rather than the workpiece side, of the fixture, and it’s the first pocket-hole jig to include a port for dust collection.

It should come as no surprise that Kreg is constantly evolving, generating both new designs and improvements to their current offerings. After all, this is a company that listens to its customers. “We use a lot of customer feedback for our redesigns and new product designs,” Todd told me, “and we listen carefully to what comes in through our customer service and technical support departments. Our focus is to give our customers more than they expect.”