Build it simple, and they will come

Recently, I received an email from one of our readers asking for help. This novice woodworker had bought a dovetail jig and spent two days trying to make it work, with no success. It brought to mind the words of Dave Keller, whose Keller Dovetail jig excels at combining simple setup with foolproof accuracy.

The Keller Dovetail jig, by contrast, is the epitome of simple setup, and does not even require visual inspection to do it right. In fact, it’s been used successfully for the past nine years at the Washington State School for the Blind. Having put it through its paces, I can understand why. On top of that, the resulting dovetails are a perfect, snug fit every time. They are accurate enough to have been certified for work on Corian®.

“Unlike many other jigs, with the Keller, the thickness of the stock and the setting of your router bit do not affect the tightness of the joint, nor its registration, and no test cuts are required. Once you have set the Keller templates accurately on the backing block, you can pick them up and use them, and in five minutes, you are ready to assemble your dovetails.”

Dovetail joints go back at least 3,800 years, but half-blind router-cut dovetail jigs were first patented around 1928. The cutting process used with most jigs has not changed much since then. Bit and stop settings are critical, and can often only be set by trial and error.

“I have had woodworkers call me up in tears telling me they have another dovetail jig, the job is due tomorrow, and they can’t get the drawers right. I have shipped jigs overnight to people in desperate straits, and gotten grateful calls asking, “Where have you been all my life?” and thanking me for saving their job.”

Not surprisingly, one of the places Dave Keller had been was making fine furniture. After a brief stint as a social worker, he wound up in Eugene, Oregon, in 1970, where he made his first piece of furniture. Hooked on woodworking, he moved to California and apprenticed with famed master furniture maker Art Espenet Carpenter. After the apprenticeship, Art hired him, and he worked there for three years. He says it was Art who was responsible for the fixture. “Few people know that Carpenter was the one who first developed the process for doing through dovetails with a router,” Dave told me.

“At the time, we were doing ultra-high-end work, and Art was one of five wood artists invited to exhibit at the new Renwick Gallery, along with Wharton Esherick, George Nakashima, Sam Maloof, Wendell Castle. For that sort of work, Art’s original shop-made jig just didn’t cut it.”

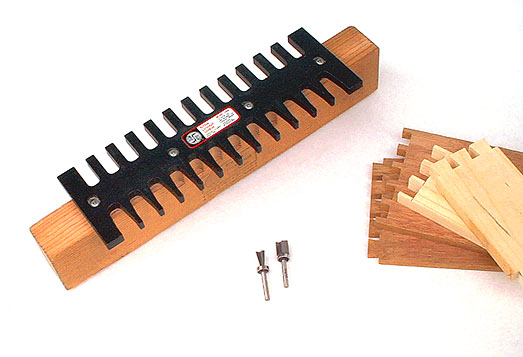

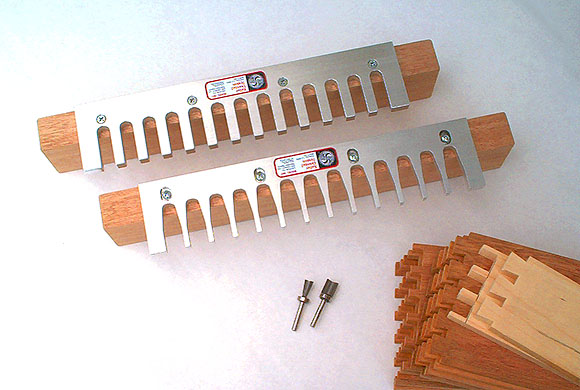

Keller redesigned Art’s original phenolic jigs to work with thicker wood stock in 1975, made accurate drawings, and took them to a machinist, who encouraged him to make them in aluminum instead. He also designed two companion bearing bits to work with them. The first run of sixteen went to Carpenter himself, and a few others at the newly formed Bauline’s Craft Guild.

The original bits had an oversize bearing, making the whole fixture work offset. Keller designed a bit with a shank-mounted bearing the same size as the cutter, thus creating the first pattern bit, a format now in widespread use. This meant that the cut and pin template were exactly the same, making lineup virtually foolproof.

He patented the design, with Carpenter’s blessing, and the Keller Dovetail company was born. Sales were slow until Keller took his jig to a woodworking machinery show in 1983. The response was overwhelming.

These days, Keller offers dovetail jigs in 36″, 24″ and 16″ versions, which variously handle wood from an inch and a quarter down to an eighth of an inch, depending on the jig. The bigger fixtures make a larger dovetail pattern, and handle thicker wood. All the jigs will do unlimited widths, unlimited length, mixed thicknesses, beveled sides, both obtuse and acute angles, compound angles, curved dovetails, box joints and knuckle hinges.

Each kit comes with the two bits needed for use, and complete instructions, with additional bits available. Recently, he added two cheaper, light-duty models for hobby woodworkers made in phenolic plate instead of aluminum. The smallest 15″ model sells for $150, including the bits, and has become his top seller. They also offer a pro clamp kit, which helps convert the jig to a production setup, and a video that shows the large variety of ways to use the jigs. The Keller products are sold directly online at kellerdovetail.com, at woodworking shows, by phone and mail, and through about 100 dealers throughout the country, mostly woodworking specialty stores.

“One of our best markets,” said Dave, “involves those who have tried other jigs, and are ready for something that is faster and more accurate. We are not very fancy. We don’t do everything. We specialize in perfect through dovetail joints with a setup that is fast and easy to learn. For drawers, boxes and smaller pieces, the whole assembly can be flipped upside-down to run on a router table.”

“People report to me with great regularity that setting up other jigs is a 15- minute to one hour chore that chews up scrap lumber along the way.”

“At woodworking shows, I tell customers to go to the competitors’ booths, have them change the wood thickness and settings, and see how long it takes to set up their tool. Then they can decide whether they want to spend their shop time setting up jigs, or cutting joints and moving on. There are always new woodworkers entering the field, and we want to be there to make their lives easier.”