Although John Murphy has been working with wood for a long time, it’s within the past few years that he has come to specialize in wooden toy models.

In 2013, he said, he discovered the book Tremendous Toy Trucks by Les Neufeld. The book includes instructions for 12 toy trucks, and “I made them all,” John said. “The first one I made was the Monster Truck. After that, I was hooked on model making.”

He started out making simple models for his two young daughters to play with or give as birthday presents to their friends. As his models became more detailed and complicated, however, John decided to display them at model exhibitions throughout Ireland, where he lives.

John had learned the skills to do woodworking with a high degree of accuracy in his work as a carpenter/joiner, especially when he worked in London on projects that included the restoration of buildings dating back to the 14th century. He has applied those skills of accuracy to his models, which are now all replicas of real vehicles: trucks, cranes, excavators, etc.

“When I decide on the model I want to make, I go online to research it. I look for photographs of every angle of the machine. I study videos on YouTube. Finally, I look for a spec sheet to give me overall dimensions, spacing between axles, etc. This can take 50 to 60 hours before I start to make the model.”

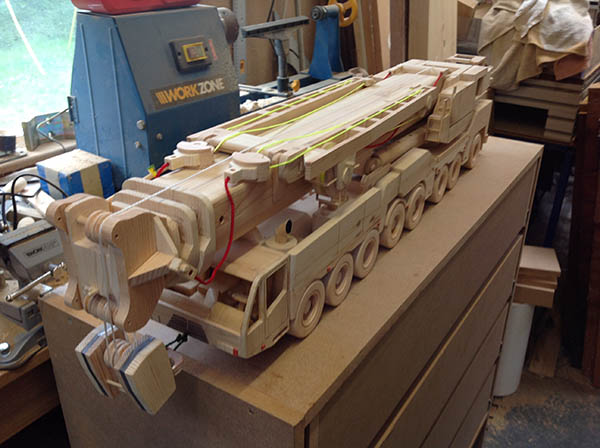

All John’s models have moving parts. “I try to make them do what the real machine does as realistically as possible,” he said. It can be a challenge, however, to cut and shape the small parts for his 1:20 scale models. “Sometimes they break; sometimes they fall on the floor and can’t be found, and sometimes the idea just won’t work, and I have to try something different,” John said.

Most of John’s models are made from hardwood floorboards. “I’ve collected leftover boards and offcuts for years,” he said, with friends in the building trades also collecting for him. The exceptions are his model cranes, which are made with engineered pine.

“The larger parts I need for the crane models need to be stable,” he explained. “If they started to warp or twist, the various parts of the crane would not fit together.”

John got started making cranes after a crane driver acquaintances saw one of his model trucks and asked if he’d ever tried to make a crane model. “Once the ide was planted in my head, it wouldn’t go away,” he said. He learned the basics of crane making with a model of a 100-ton Terex Demag mobile crane.

Since then, he’s made six more cranes, with the models becoming more complicated and realistic, culminating in the most recent model, a Terex Demag AC 500-2. The real world version is a 500-ton crane. John’s model, when fully assembled, is about 18 feet high and does everything the real crane does — “except lift 500 tons.” John says he’s found that making cranes is his favorite type of model making “because it’s a tremendous challenge.” Kavanagh Crane Hire, the largest such company in Ireland, has four of his cranes on display in their headquarters reception area.

Both his cranes and his excavators also use some of the few metal parts in his models. Since both need to be capable of rotating through 360 degrees smoothly and safely, John uses a metal bearing to accomplish this. The cranes also need ballast to keep them balanced, which John achieves by making the crane weights hollow and filling them with scraps of metal. Black electric cable models hydraulic hoses.

One of John’s recent projects was a fully functional model of the 90-ton Caterpillar 390F L excavator. “It’s the first model I’ve made with working wooden tracks,” John said. “The tracks were not easy to make, but they turned out better than I had hoped for a first attempt.”

Eventually, John would like to turn his model making into a source of income, but regardless, he said, “model making is a marvelous hobby, and I know it will give me years of pleasure and a great sense of achievement.”