It may be an understatement to say that Seumas McCombie is Scottish. He’s really Scottish. He’s so Scottish that it would be improper to even try to make a joke about how Scottish he is. Besides, we can’t think of one right now. Seumas, however, follows a long tradition of Scottish engineers and inventors by distilling years of experience and wisdom into a tool many could benefit from. He is the inventor of the Jimmy Jig, a jig that’s designed to make table saws safer, more accurate and more useful. He has spent 45 years as a contractor and has learned a few things along the way. Some of that know-how has been built into the Jimmy Jig.

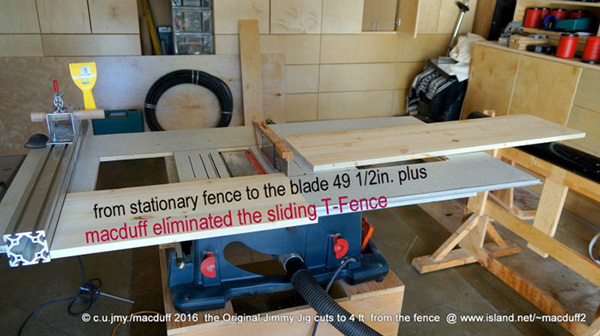

The jig itself is somewhat difficult to describe because it’s both simple and complex at the same time. At its simplest, the jig is a 5′ by 30″ laminated board with a fixed fence on one end. This is designed to replace the sliding fence your table saw came with. Instead of sliding the fence along a slot, this platform and fence is designed to move as a unit across the table, perpendicular to the saw blade. To do this, there is a large rectangular hole (which Seumas calls the aperture) in the center of the platform. The jig has a wraparound L-shaped bracket under the long side of the platform that is designed to slide it securely onto the top of the table saw.

Then you simply slide the jig on the table saw, raise the blade to the level you want it, and clamp the jig to the top. You’ve now got a very secure fence that won’t be going anywhere while you’re cutting material. Seumas originally designed the jig, 25 years ago, to help him cut 4×8 sheets of plywood as a one-person operation. That one-person sheet cutting is accomplished with the “outrigger” he designed.

The aperture of the jig is where it gets a little more complex. Seumas designed it with two inserts that can slide around in the aperture and create zero clearance for the table saw blade or dado blades. He’s also designed an insert for a router, effectively turning the jig into an extension router table.

Seumas has all ten of his fingers after 45 years as a contractor, and that’s no accident. He’s designed, and continues to design, safety features into the Jimmy Jig. First, there’s the 4″ splitter, which he says is much safer than the typical 3/4″ splitters that most saws come with. Second, he’s designed an antikickback pawl that rides the fence and it is positioned in front of the blade ? not behind it. That’s another criticism he levels at table saw manufacturers. He says that most have their pawls behind the blade where it’s often too late to prevent kickback.

A more elaborate safety system is currently being developed for the Jimmy Jig. This will consists of a suspended bar that rides the top of the fence. It’s on rollers and is suspended about 4 1/2″ above the wood. This bar, Seumas has discovered, slows down the cutting process by a few seconds, but it also makes the operator think about where his or her hands are in relation to the blade. “But that’s of no consequence when you want to keep 10 fingers for a lifetime,” says Seumas.

Probably one of the more important things to remember about the Jimmy Jig is that you can’t really buy a finished jig. Seumas only sells the plans for the jig and you will need to build it yourself. He says it’s a quick weekend project and uses mostly scrap wood. The plans can be ordered from his website and run $21 for U.S. residents and $30 for Canadians. Seumas lives in Port Alberni, British Columbia.