Nearly 50 years ago, Douglas Howard was approached with the perplexing question of how to restore the original color and luster of a wood finish, as well as fix minor blemishes, without removing any of the original finish. It seems do-it-yourselfers in the late 1960s were as aware of the effort and pitfalls that go along with stripping and refinishing wood as DIYers are today. Then, just as now, any product that can reduce some of that sweat equity — and minimize the risks of ruining a finish — was a welcomed alternative to starting over.

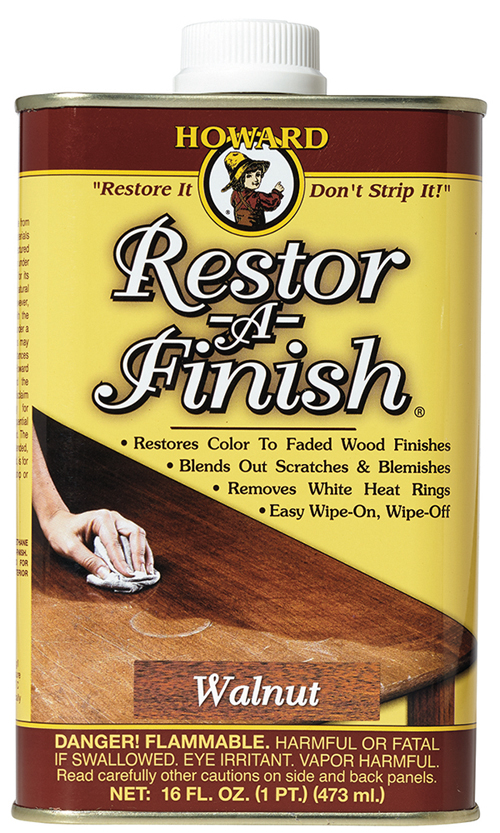

Howard set out to find a solution, and the results of his efforts in the test lab culminated in the product you can still buy today: Restor-A-Finish®. It’s a one-step wipe-on blend that can be used over any traditional wood finish, including shellac, lacquer and varnishes other than polyurethane. Restor-A-Finish penetrates through the finish without removing it, according to the company’s product description. It blends away white heat rings, water marks, sun fade, oxidation and smoke damage — many of the usual forms of deterioration and damage that can lead to stripping and refinishing.

The safety data sheet for Restor-A-Finish on Howard’s website reveals that it’s a mixture of several solvents, including isopropyl alcohol, acetone and xylene, plus asphaltum and other petroleum distillates.

Justine Evans, national sales manager for Howard Products, won’t reveal its actual formula, “but I like to say it is exactly what it says it is: it’s a restorer,” she clarifies.

Evans says the unique formula contains “just the right amount of solvent blended with a small amount of stain and mineral oil.” And, the application process is simple: wipe the fluid on and wipe off the excess. Restor-A-Finish is formulated in nine wood-color shades to approximate the tones of most common furniture hardwoods, including maple/pine, oak, cherry, walnut, mahogany, and darker stained walnut or oak, plus an ebony brown.

Most of us have probably heard the warnings offered by antiques experts that stripping off original finishes can devalue them at auction, sometimes significantly. Evans says Restor-A-Finish provides a safer form of preservation for these heirlooms. “(Since) it will not remove or soften the existing finish, Restor-A-Finish maintains the original ‘patina’ of an antique finish and its character and value as an antique,” she says.

Most of us have probably heard the warnings offered by antiques experts that stripping off original finishes can devalue them at auction, sometimes significantly. Evans says Restor-A-Finish provides a safer form of preservation for these heirlooms. “(Since) it will not remove or soften the existing finish, Restor-A-Finish maintains the original ‘patina’ of an antique finish and its character and value as an antique,” she says.

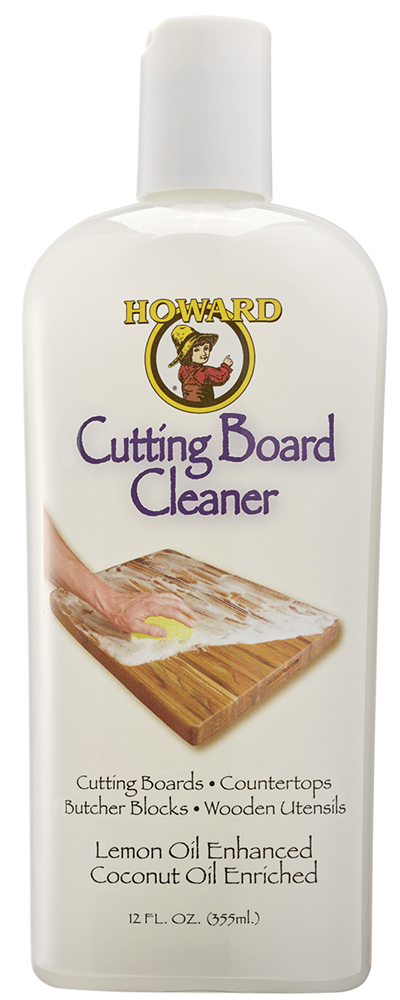

In addition to Restor-A-Finish, Howard Products manufactures 14 other products that provide do-it-yourself solutions for various wood care needs. For instance, Woodworker’s Journal often receives reader questions about how to finish and maintain wood cutting boards and butcher block surfaces. Consumers want food-safe finishing solutions that are both easy to use and also enhance the natural beauty of the wood. Howard Products has three options that can help: Cutting Board Oil, Butcher Block Conditioner and Cutting Board Cleaner. The first is a clear food-grade mineral oil enriched with vitamin E. It’s intended for raw wood surfaces as an initial finishing step. Evans says at least two coats of oil should be applied to saturate the surface, with 20 minutes to an hour’s drying time in between, depending on wood thickness and how quickly the wood absorbs the oil.

“After a good seasoning with Cutting Board Oil, you can then maintain the wood with our Conditioner (a blend of mineral oil, beeswax and carnuba wax). The conditioner helps protect the wood by keeping the mineral oil in and the moisture out,” she says.

The company’s Cutting Board Cleaner, Evans reports, is a new product. “We were getting the same question over and over again: ‘How do I clean my cutting board before applying the conditioner or oil?’ There weren’t any quality cleaners we could recommend, so we decided to make one that we would feel good about selling.”

Evans explains that the product is formulated with lemon oil and coconut soap to safely clean any wood surface that comes into contact with food. It’s made to be used in tandem with Butcher Block Conditioner — clean, then condition as a two-step process.

Howard Products’s other wood care options include citrus-based cleaners, wood polishes, paste waxes, fill sticks for repairing blemishes and a conditioner with UV protection for patio furniture. The company also makes a powdered additive for water-based paint, called Chalk-Tique, to simulate the look of today’s popular chalk-style and milk paints. Then there are various options for polishing metal and cleaning and conditioning leather or upholstery.

“Our mission has always been to enhance our customers’ living environments, and we strive to offer a full line of the highest quality polishes, waxes and restorers available,” Evans says. “We’ll continue to pursue new and creative ideas that have the potential to make any living space someplace you are proud to call home.”

Learn more about Howard Products by clicking here. You can also watch videos about product application and expected results by clicking here.