In last issue’s eZine, after highlighting an online discussion about homemade tools, we asked eZine readers if any of you have made homemade tools. It turns out, you have. – Editor

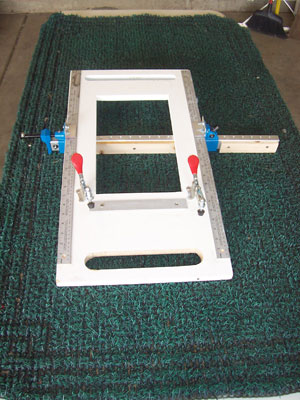

“This sled replaces the wife who had to hold and guide a 4×8 sheet of MDF while I was cutting it on the table saw. Now I can adjust the guide fence to any width cut between 1/8″ and 27″ without using up a long straight edge and clamps. It is a very fast setup, and cutting is very accurate with the moveable guide fence.” – Morry Hansen

“There was a thickness sander that could sand a 28″ wide board at a time. The barrel turned at about 3,600 rpm. Took me two years to build, and I gave it away when I moved (it may still exist somewhere in Granite City, Illinois). I never took a picture of it. Also, there was a roller chain table lift on four 3/4″ threaded rods that had 0″ to 10″ travel. I think the hardest part of that one was putting the 5/8″ heater hose over the 3/4″ feed rods (finally accomplished with the help of 150psi, but not until I slipped and sent a 3′ x 3/4″ rod flying across the garage.) Survived to carve another day.” – Riley G.

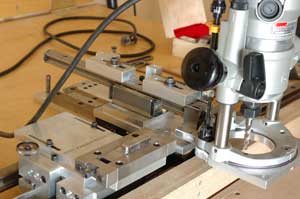

“This is a little bit of an an unusual type of tool. It started because a good fixture for dovetails was too much money for my taste, so I started tinkering for a while and, after about a year of improvements, this is the almost final design. The machine is actually capable of doing many things, with the proper attachments, like: dovetails, tenoning copy machine, table legs, and a lot more (limited by imagination).” – Maurizio Gaultieri

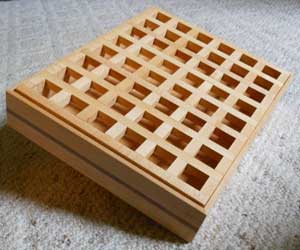

What the Lattice Cutting Boards Look Like

Also, back in the Q&A section of eZine 294, we had a query from a reader about why the lattices in his cutting boards warped. While our experts answered the question, they also wanted to see some photos of the cutting boards in question. The reader obliged. – Editor

“I was both honored and flattered that you included my question in the recent edition of the Woodworker’s Journal eZine. Mr. Inman expressed interest in some photos. While these certainly are not professional, they should give an idea of the overall piece. The walnut inlay and maple splines of the case are reclaimed wood from two separate buildings in Traverse City of historical importance. The European beech sides are of sentimental value, as that wood belonged to a playroom table I built for our (then) toddler daughter while we still lived in Hamburg, Germany. It was a hard choice to sand off the patina of her childhood years!” – Michael Popp

Congrats, Gramps!

And, of course, the congratulations to Rob on the birth of his first grandchild continue to come in. – Editor

“I would like to congratulate you on becoming a grandfather! May the Lord give you many more! I would also like to say how much a appreciate your writing — I feel as though I know you, at least a little bit! You do seem to let your personality show through, which I appreciate. I also recall that, some time back, you asked a question for readers seeking advice for your home. You replied to one writer that your wife had passed away due to cancer. I¹m certain that the ache in your heart doesn¹t easily end. I often think of this as I read your writing. You seem to have done an excellent job carrying on, even though there has to be a lot of pain. Although I’ve done a fair bit of woodworking in the past, my work with international students - which I really love – keeps me more than occupied, and I don¹t get to do much woodworking. In fact, I¹m setting up a new basement shop, and that takes a lot of time as well. I hope I can get more done soon! I read and dream about what I¹d like to do! Again, thanks for what to do to encourage us!” – Allen Busenitz