Our experts asked for further clarification from this reader who had a question in the Q&A section of eZine 298, and here is his expanded explanation. – Editor)

Regarding my question on the rule joint and countersunk hinges, let me explain my problem further. When I countersink the entire hinge, the notch appears at the bottom on the roundover side of the rule joint, just where I have to countersink the barrel of the hinge. How do I avoid the notch if I want to countersink the entire hinge? – Jim DiRenzo

Tim Inman: You can’t.

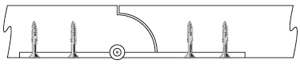

Chris Marshall: Once a rule joint is assembled and with table’s leaf down, the mortise for the hinge barrel and the barrel itself should not be visible on the roundover at all when viewed from above. That’s because the hinge barrel should be inset from the edge of the table top so it is positioned almost at the center point of the roundover — not at the edge of the radius where you could see it (see the illustration here). From your explanation, unfortunately it sounds like that’s where you’ve mortised for the hinge barrel — at the edge of the roundover. Also notice that the shorter of the two hinge leaves should be attached to the tabletop side of the joint; the longer hinge leaf attaches to the table leaf. With the hinge barrel located at the center of the roundover, the table leaf’s cove profile can rotate up or down properly without binding against the roundover. A rule joint doesn’t come together like a typical door-hinge joint does — the hinge barrel doesn’t split the two parts “at the seam,” so to speak. It might be a good idea to find hardware installation instructions in a woodworking book or a magazine article to help guide you further here.