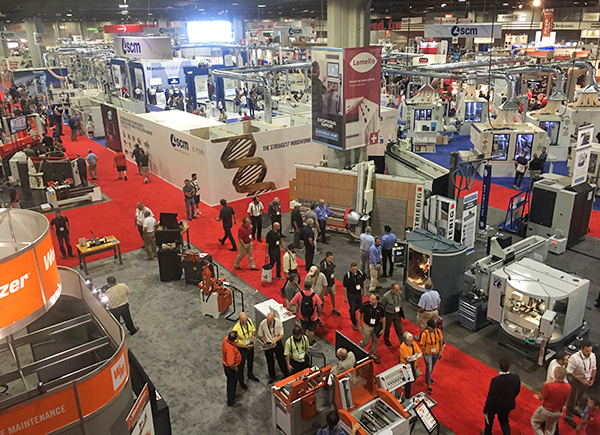

In case you missed Rob’s editorial in last week’s issue of the Weekly, or our Instagram posts that followed over the next several days, we were in Atlanta — along with an estimated 30,000 to 40,000 other attendees — at the International Woodworking Fair (IWF). I’ve always found it tough to sum up what the “all” of IWF is for those who can’t go, because it’s a four-day blitz to the senses: the roar of automated machinery milling cabinet doors, sanding panels or whirling full-size sheet goods around on robotic arms like they’re weightless; enormous, house-sized dust collectors keeping the convention center air clean; plus the steady whine of blades, cutters and giant induction motors carrying out impressive tasks and driving big sales. On top of that, there’s the buzz of loud conversations and commotion, as around 1,000 vendors kibitz with attendees over new products, make deals and strategize how to move their businesses forward.

It’s both invigorating and exhausting.

Now, most of the industrial “noise” at IWF doesn’t really apply to weekend woodworkers or the magazines and social media influencers that support this great hobby, but we go to the show because, in the midst of the bustle, there are products we hope you’ll find intriguing or at least amusing. It also offers a chance to say hello to our industry partners as well as some familiar faces from the social sphere that might also prompt you to buy a ticket to attend the next IWF in 2020.

So, what did 10 miles (literally!) of walking two massive exhibition halls shake out for me? Well, this isn’t all of it by any means — be sure check out our Instagram page for more of those details — but here are a few highlights.

Bessey GearKlamp®: Clamping is never easy in close-quarter situations, but Bessey has engineered these new GearKlamps to help. Available in 6-, 12-, 18- and 24-in. bar lengths, they’re a modified F-style clamp with a big difference: instead of the handle being located on the lower jaw, it’s now wrapped around the clamp bar. Twisting the handle drives four internal gears to tighten the lower jaw with up to 450 pounds of clamping force. Thumbing a quick release button sets it up fast or releases the tension. While pricing wasn’t yet available, these new GearKlamps will reach Bessey retailers in October.

Axiom Stratus: Axiom Tool Group focuses most of its R&D on state-of-the-art CNC machinery, which is why these new cylindrical Stratus air cleaners were a big departure! Their three-speed, 120-volt “tube axial” fan motors draw around 1,000 cubic feet per minute of dirty shop air through a washable outer foam filter and then a pleated inner filter to scrub it clean of wood dust and other particles down to .5 microns. Their reasoning for moving an ambient air cleaner to the floor, rather than hanging it from the ceiling as usual: Why not catch the dust where it’s made, closer to the source, instead of waiting for it to float up? And, this ambient air cleaner is one you can easily move around the shop when needed or clean without climbing a ladder. That all makes sense to me. Two versions of Stratus are slated for a December launch: the “standard” white Stratus will be powder-coated steel and sell for around $499. A Pro model ($699) will be enhanced by an active charcoal foam filter and a stainless steel shell.

Festool CT Cyclone: Ever wished the disposable bags on your Festool CT 26, 36 or 48 dust extractor would take longer to fill up? Well, one way to make that happen is to separate the bulkier, heavier debris out first, which is precisely what the new CT Cyclone will do. It mounts atop your CT extractor and consists of a two-piece Systainer with a pre-separator device inside the top portion. When dirty air whirls through it, coarse debris and shavings empty into a clear, static-free 20-liter plastic container beneath. The finer dust that doesn’t fall out of the airstream travels down into the extractor, as usual, to fill the bag. Slated for availability this fall, the CT Cyclone (model CT-VA-20) will retail for $375 with one lidded collection container. Additional stackable containers will sell for $70 apiece or in a three-pack for $180.

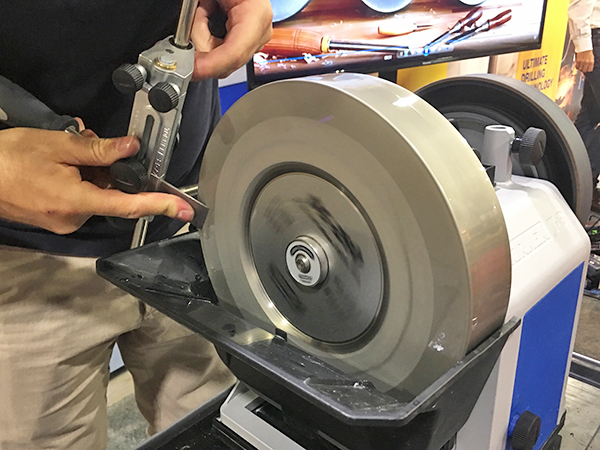

Tormek Diamond Wheels: Tormek’s wet sharpers have been around for a long time, but their abrasive wheels haven’t changed much — until now. New at the show, Tormek now offers coarse (360-grit, $330), fine (600-grit, $299) and extra fine (1,200-grit, $315) diamond-coated metal wheels. Upside: they won’t wear like abrasive wheels do, and the wheel’s diameter won’t decrease as a result of re-flattening, which diamond wheels don’t require. And, unlike conventional abrasive wheels on Tormek machines, these new diamond wheels can be used either to hollow-grind on the rim or flat-grind on the wheel’s face. The company has designed a new Multi-base accessory (model MB-100) to facilitate flat-grinding. Tormek’s new diamond wheels will fit all previous 10-in. Tormek machines.

But IWF isn’t just about showcasing new products that are certain to go to market. One of the aspects I’ve always appreciated about the show is that some manufacturers use it as an opportunity to share prototypes in order to get some preliminary feedback. Here were a few examples:

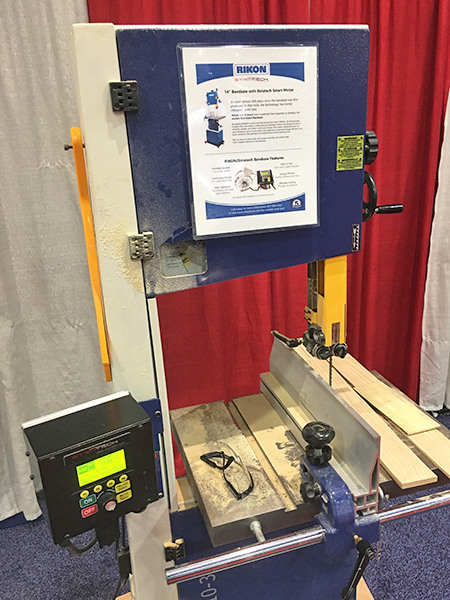

RIKON Bandsaw DVR: Many wood-cutting band saws are limited to, at most, two speeds that are set by changing the drive belt position on the flywheel pulleys. It’s a hassle to do. RIKON Power Tools plans to offer a 14-in. band saw, possibly by the end of this year, that will have an infinite, variable-speed DVR motor — similar to some lathes and drill presses. Benefit? You’ll be able to set this band saw to the optimal cutting speed for the blade, task and material at hand by simply pushing a touch screen and twisting a dial. One of RIKON’s technical experts told me that the blade speed for cutting wood optimally should actually be much faster than the speed rate we are limited to on our conventional-motor saws. A DVR motor also offers consistent torque and fewer internal parts to wear out. Eventually, RIKON says it plans to offer DVR motor/controller retrofit kits for other band saw brands, too.

Oliver Model 4300 12-in. Jointer/Planer: Here’s another pre-production concept that at least offers food for thought. It’s a two-speed, 120-volt, 2hp motorhead that looks quite similar to a popular yellow portable thickness planer you may already own. But this setup has the 12-in. planer mounted on rails to an almost 9-ft.-long steel table. In the “planer” mode, the machine’s internal feed rollers draw stock past the cutterhead as usual, and the table serves as an extra-long infeed/outfeed support. Switch it over to “jointer” mode, however, and the entire motorhead can be manually slid along the table’s length, for jointing the top face of long boards or slabs. Retailing for around $2,400, an Oliver product manager told me the company will go to market with this machine if it receives 100 orders or more. But, due to feedback from IWF attendees, Oliver is considering re-engineering the jointer/planer to handle 15- or even 20-in.-wide stock instead. Time will tell if the 4300 becomes a permanent addition to Oliver’s product line, but it was a curiosity worth seeing, nevertheless.

Bow Products Pushstick: Over the past few years, Bow Products has been making rip cuts and other machine operations safer with its foam-insert FeatherPRO featherboards. The company also offers a new GuidePRO device for supporting resaw cuts at the band saw. Well, Keith Bow, the inventor behind both of these devices, was in the show booth offering versions of a preliminary pushstick he has in mind, next. The final form of this prototype is yet to be determined — it might be a complete handle, or just the “working” end and you create your own handle from scrap. But either way, its tip would be made of the same dense, replaceable foam material that’s found on the FeatherPRO. That way, even if this pushstick were to accidentally make contact with a spinning blade, it wouldn’t damage the blade or increase the chance of a kickback. And, the foam tip would be easy to pop out for replacement.

IWF has also been a venue for seeing woodworking celebrities such as Scott Phillips or Norm Abram. Our social media landscape is bringing a continuous stream of new woodworking content from today’s hottest “influencers,” and several were on hand at this year’s show. “The Wood Whisperer” Marc Spagnuolo signed free copies of his book “Hybrid Woodworking,” courtesy of Titebond Products, in their show booth. And, attendees could stop, talk and take selfies with both Matt Cremona and April Wilkerson, while also looking more closely at the current and new product offerings from Triton Tools.

IWF 2018 is now in the rearview mirror, but we’ll continue to provide new-product coverage from the show in future issues of the Weekly as well as in our print issues of Woodworker’s Journal. One thing is for certain, this year’s show proved that the woodworking marketplace is alive and well — and that’s a good thing for all of us!