A couple of years ago, a question arose within the pages of Woodworker’s Journal concerning the origination of “Masonite®.” Masonite was the brand name of a product invented in 1924 by William H. Mason in Laurel, Mississippi. Mass production began in 1929, and it was produced in Mason’s hometown right up until the 1990’s.

Still known at times as “masonite,” it is more commonly referred to as hardboard. It is made in as many as 28 plants in the United States and in many more throughout the world. It is most commonly made in flat sheets of 1/8” to 1/4″ thick. Hardboard is much denser than the wood from which it is made and is very heavy. In fact, it is so dense that it may sink in water and will rapidly dull carbon steel woodworking tools.

The advantage of hardboard is its near-perfect uniformity. It is made from many species of wood with vastly different properties. These properties are made uniform in the manufacturing process. The original Masonite was an all-natural product consisting simply of wood, water, and linseed oil. (Linseed oil is produced from the seed of flax, a grain crop. Linseed oil was also the main ingredient of linoleum, which was developed in England in the 1860s).

Since its inception, hardboard has  been used for things as varied as license plates during steel shortages of the Second World War to roofing underlayment. Today, since hardboard is an all-natural product, it is used by commercial bakeries to support cakes. It is also in wide use as skateboard ramps, to protect high-end floors during construction (and to enable smooth rolling of dollies across those same floors), to construct film and theater sets, musical “wobble boards” and in some electric guitar bodies.

been used for things as varied as license plates during steel shortages of the Second World War to roofing underlayment. Today, since hardboard is an all-natural product, it is used by commercial bakeries to support cakes. It is also in wide use as skateboard ramps, to protect high-end floors during construction (and to enable smooth rolling of dollies across those same floors), to construct film and theater sets, musical “wobble boards” and in some electric guitar bodies.

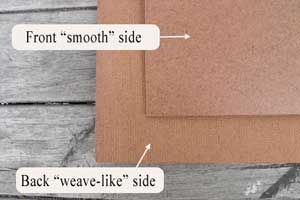

The manufacturing process involves very high pressures and heat. I remember, as a young man traveling through Laurel, Mississippi, the very distinctive smell of hot wood and linseed oil coming from the Masonite plant. It was not an unpleasant odor. You have probably encountered hardboard in many places. It was commonly used in the backs of televisions in the 1970s and 1980s. Another use of that type of hardboard is for the pegboard most of us use in some way in our shops. This kind of hardboard has one finished side and one rough side (S1S). This is the result of how it is manufactured. I commonly use a second type of hardboard to protect my workbench and countertops in my shop. It is finished on two sides (S2S). It is much easier to flip this board over when paint or glue spills on it or I accidentally damage it, than to replace the benchtop. There are two different processes used to manufacture hardboard, and these result in differing identities and qualities. I’ll identify the differences in the different manufacturing processes in the next installment and how they affect your uses of “Masonite” in your woodworking projects. I’ll also show you how Medium Density Fiberboard is a direct descendant of the original Masonite.

Tim Knight