It’s tough to do much woodworking without wood. Keeping the following five sources in mind can save you money and expand your options while sometimes also uncovering some truly extraordinary material.

1. Home centers are obvious destinations for wood, but inventory is limited to mostly construction lumber and plywood. A small selection of hardwoods will have top-dollar pricing. You can do much better elsewhere.

2. Specialty lumberyards, advertised in woodworking publications and online, typically stock a wide variety of both domestic and exotic species options and board sizes. Many carry one-of- a-kind figured and slab lumber. Their staff are often woodworkers who tend to gladly share their expertise. A yard that specializes in furniture-grade lumber for the general public can become your best friend. Some of these specialty yards also sell their lumber on the Internet, increasing your options for species not found in your region.

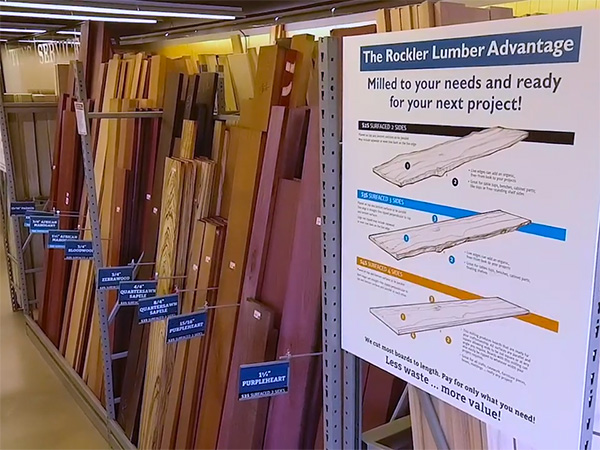

3. Woodworking retail stores such as Rocker are also staffed with experienced woodworkers and carry a moderate to extensive range of wood species and sizes. The lumber is generally surfaced and, when sale-priced, can provide good value. A store has the added advantage of being a one-stop shop for everything else you need — hardware, glues, finishes, tooling, jigs and many other supplies. Rockler also sells some hardwood online.

basement. Often it’s sold for rock-bottom pricing.

4. Classified ads on Craigslist and other similar listing sources can put you in touch with local sawyers who cut, dry and sell lumber on a smaller scale. Want ads are also a great option for buying caches of boards stored in barns, sheds and home shops. Often, families of deceased woodworkers are willing to sell off inventories of lumber for very modest prices, particularly to buyers who will put a loved one’s precious boards to good use.

5. Backyard lumber might seem implausible, but there’s no reason your stormdowned maple or overgrown oak tree couldn’t become excellent lumber if you can process the log. Here again, classified ads can help. Find an enterprising sawyer with a portable band saw mill who can come and slice the log into green lumber. You’ll need to air-dry the material for at least a year, or have it kiln-dried, but the sawyer may have suggestions for who could take care of that part of the process, too.