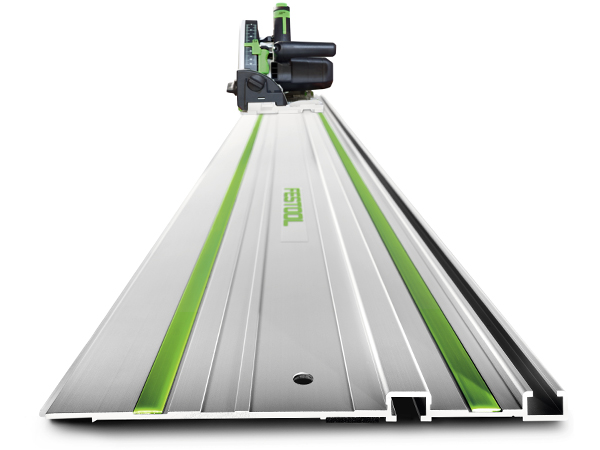

After 11 years, it’s finally happened: Festool officially announced last month that it has begun to make its aluminum guide rails for track saws, routers and jigsaws in its Lebanon, Indiana, headquarters. This marks the first Festool products that are made in America.

“There’s a press release from 2006 announcing our move to Lebanon, Indiana, that also includes a statement regarding our intention to begin production in the U.S.,” says Rick Bush, Festool USA’s director of product marketing. “We are very proud to say that we have progressed in our plans and are true to our word in (that) announcement.”

Festool has been a popular brand of precision woodworking and contractor tools here in the U.S. since 2000, but its roots as a tool manufacturer in the European market go back much further than that: it was founded in 1925 by Albert Fezer and Gottlieb Stoll as “Festo” — an amalgamation of their last names. The two men designed the first transportable gas-powered chainsaw that year, and their company has followed with many other stationary and portable power tools in the decades since. But, up until this year, Festool has manufactured its entire tool and accessory line outside of the U.S. in just two global locations. Its main production facility is in Niedlingen, Germany, which is located in the manufacturing and engineering hub of the Stuttgart area of southern Germany. The company also builds products in the Czech Republic. It owns that plant there, too, which is staffed with Festool employees that are overseen by its global headquarters team.

Bush says the move to begin making guide rails in Lebanon (just outside of Indianapolis) is a “logical” place to start for a number of reasons. For one, guide rails — known almost ubiquitously these days as “tracks” — are essential accessories for the company’s TS line of track saws. Track saws are among Festool’s most sought-after power tools by flooring installers, cabinet shops and custom woodworkers who buy Festool products here in the States.

There are other benefits, too, which include production capacity, lean manufacturing, storage and logistics. “The ability to produce products here takes pressure off of our main manufacturing facility while providing faster response to stock level needs,” Bush says. “Products produced here will no longer need to make the long trek by sea from Germany, which provides greater flexibility for our planning purposes.”

Additionally, guide rails provide a good testing ground for future manufacturing opportunities. Bush says that while guide rails are technical products that require tight quality control to ensure proper function, “they are less complex than our machines, so it makes sense to begin here as we build our competency in the U.S. We must build a production team, the processes and flow to meet the high demands for quality and efficiency that Festool is known for.”

Lebanon expanded its building in 2016 to accommodate the new production line, which arrived earlier this year. That equipment was built and tested in Germany before it was shipped to the U.S. It took a few weeks to reassemble and test the line before the first guide rail samples were manufactured.

“Our first ‘official’ rails were made for quality checks. We had to produce units to be inspected by our headquarters team in Germany to ensure that they met all of the requirements defined by our rails,” Bush says.

But, that process has gone quickly, thanks to the support Lebanon has received from Festool’s production management team, Bush adds. “In practicality, it wasn’t a race to build this line, and every precaution was taken to protect the equipment, which includes a very sensitive pre-production testing component that helps ensure high quality production.”

Lebanon has added a small team who are responsible for guide-rail manufacturing, because the efficiency of the line doesn’t require a large workforce. The new team has been cross-trained in all aspects of production line and other roles that support logistics. “(They’ve) been trained extensively on the identical lines in Germany and are supported by production managers with deep knowledge and experience,” he says.

While Festool’s official press release regarding guide rail production indicates that U.S.-made rails will begin shipping throughout the U.S. and Canadian markets in late 2017, Bush could not offer further comment about whether all guide rails in the North American market will be Lebanon-made by the end of 2017. He also could not comment about whether the materials that are required to produce guide rails in Lebanon will be obtained from North American sources.

If the venture into U.S. guide rail production proves successful, readers might wonder whether that will lead to other Festool accessories, or even power tools, being manufactured here instead of abroad.

“We do intend to expand our production capacity to build more and more products in the U.S.,” Bush offers. “This will provide the capacity we need to support the market while also improving our logistics.”

And in regard to this new “American-made” initiative, Ole Held, CEO of Festool USA, had this to say: “German engineering and American manufacturing is a powerful combination. Launching a U.S. production line will allow us to expand the Festool presence in North America and strengthen our commitment to create innovative, precise, superior quality products.”

Learn more about Festool guide rails and other tools and accessories by clicking here.