Track saws are game-changers, but there are some very basic things to remember. Here are three tips to keep your cutting right on track.

Theoretically, you can make a track as long as you like by joining shorter tracks together. Most tracks have square ends that are suitable for joining, but it pays to double-check. Whenever joining tracks, use a reliable straightedge to ensure that they join straight and true before tightening down the connectors.

For most track saw cuts you need to go all the way through the material, which means anything underneath is also going to get cut. To protect workbenches and floors (and prevent serious damage to blades on concrete), get a sheet of rigid foam insulation. It acts as a solid, sturdy sacrificial base you can use repeatedly with no damage to your bench or blades.

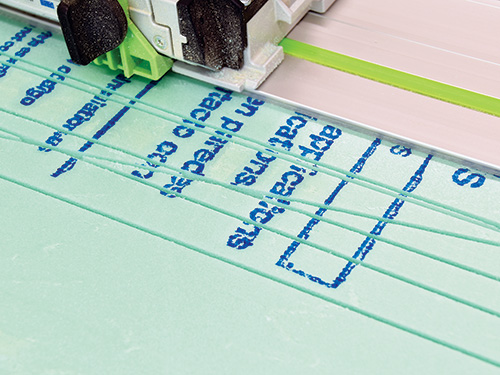

Track saws already deliver arguably the cleanest cuts around. But some materials, such as laminate countertops or plywood with paper-thin veneer, are still prone to tearout and splintering. To help prevent this, before making a full-depth cut in the workpiece, do a shallow scoring cut about 1/16″ deep. Then, lower the blade to make the full cut.