I’ve got a redwood slab that measures 4-in. x 32-in. x 12-feet, and it needs to be dried correctly. How do I do that to keep it from warping, checking or cracking? I am pulling out what little hair I have left to figure this out, and I look forward to any advice. – Jerry Fischer

Tim Inman: Successfully drying thick lumber takes a lot of time and attention. Trying to enhance natural drying on a board this thick is not something a home workshop can do. If it is important, take this lumber to an experienced sawyer who has his or her own drying kilns. They can do it, where you cannot. Why? They have enhanced digital monitoring equipment and enclosed steam chambers that are computer controlled. They also “have done this before, kid,” as my dad would have said.

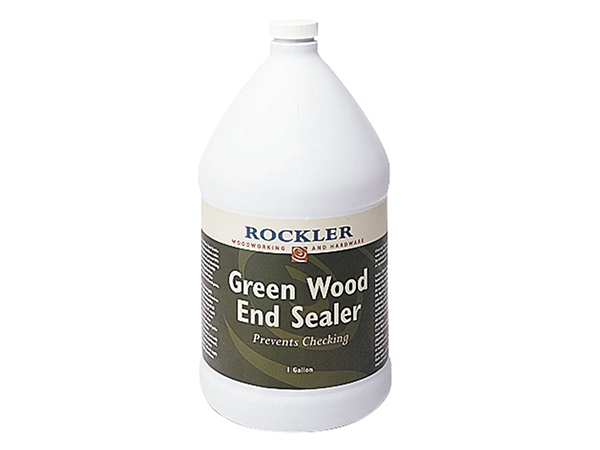

Chris Marshall: Jerry, that’s a sizable slab of lumber you’ve got there, and I can see why you wouldn’t want it to be lost to the negative effects of improper drying. Air-drying a chunk of wood that large for furniture applications is going to take many years unless you get it kiln-dried. I’d start searching local kiln sourcing, as Tim suggests. You could also run a Craigslist want ad in your area to see if that turns up any options. In the meantime, I’d coat the ends of the slab with a thick latex paint or glycol/wax emulsion, like Rockler’s Green Wood End Sealer, to slow down water loss through the end grain. Put stickers underneath the slab so that air can circulate all around it, and store it on a flat surface in a cool, dry place with good ventilation.