When Michael Williams and Connor Crook bought Diamondback Toolbelts this year, their goal was to take a decades-old venerable brand and make it even better. What they couldn’t have seen coming was the National Football League (NFL), who contacted them just a week after relaunching Diamondback to the market.

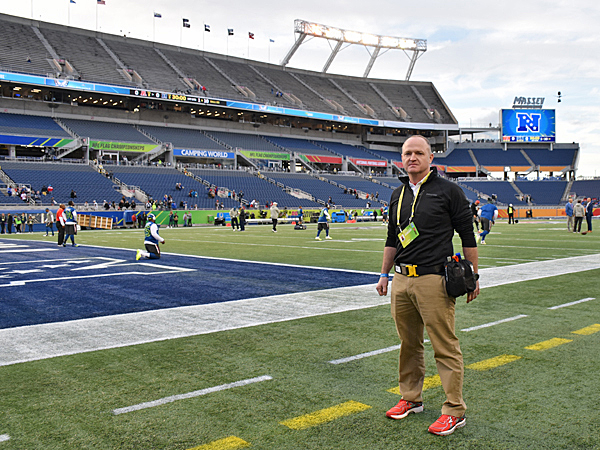

“One of their VPs was looking for custom communications tool belts for every coach in the League,” Williams says. “Next thing you know, I’m on the sidelines of the Pro Bowl with a handful of prototypes I’d personally designed and sewn … did I mention I taught myself to sew? Ha!”

While Williams considers being approached by the NFL the “opportunity of a lifetime,” it wasn’t just lucky happenstance. A couple of years ago, he founded Calavera Tool Works, which makes a line of integrated gear bags for jobsite users and workshops, as well four styles of handmade leather work aprons. His products are sourced and assembled entirely in the U.S, and they’ve been gaining traction in the marketplace quickly. Williams also knows his way around the world of savvy marketing — he was VP of marketing for Festool USA for several years, prior to starting Calavera.

It also helped that Diamondback Toolbelts are a step ahead of most other tool belt systems, in Williams’s estimation. They were designed by carpenter and windsurfer Jim Skelton in the early 1990’s. Diamondback’s system of interchangeable pouches and holsters are based on nylon and webbing that’s lightweight and durable, modeled after windsurfing gear.

“Those pouches are the closest thing you’ll find to indestructible. Every day we find more nuances that demonstrate the level of care and thought that went into the design,” Williams adds.

That jobsite ruggedness has earned Diamondback a cult following of sorts over a quarter century, Williams has learned, and the two new owners intend to take that legacy a step further. “With my marketing and product background and Connor’s understanding of processes, we’re going to build something really special through better organization and improved marketing strategy.”

And when a potential client as big as the National Football League knocks at your door with a problem to solve, luck favors the prepared. Diamondback’s integrated tool belt system, in some derivation, seemed a plausible solution to the League.

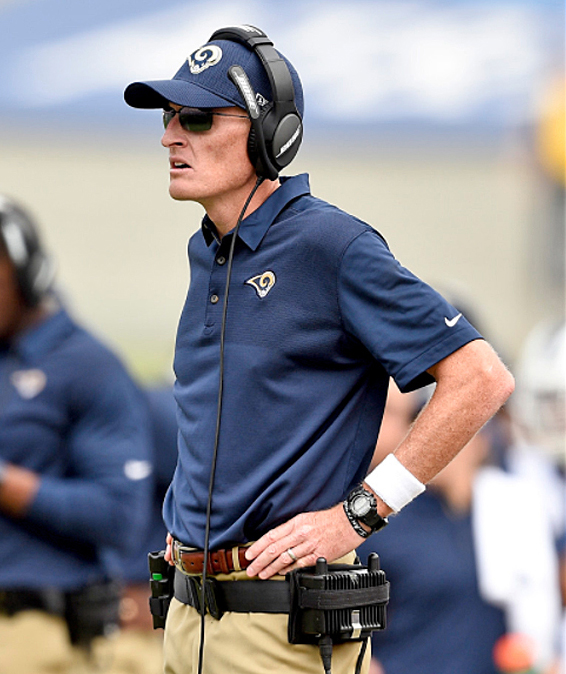

Here was the conundrum: every coach wearing a Bose® headset requires both an intercom and a radio, worn at the waist. “The belts they were using before were difficult to get in and out of and worse, provided virtually no security or protection for those extremely high-dollar support devices,” Williams says.

Some quick thinking, followed by plenty of prototypes, conference calls and even late-night texts with League officials led to the Diamondback belt system that Williams presented to NFL brass.

“Our finished commbelt is built on the idea of personalization and customization, with device-specific holsters that can be secured around the body according to each coach’s needs and comfort,” Williams explains. “The holsters provide another measure of protection for the devices, too. On top of that, we incorporated these incredible Cobra quick-release buckles, making them super easy to put on and take off … We’re using only the highest grades of materials and components, with all our manufacturing done here in the USA.”

The NFL was impressed and awarded Diamondback a contract.

“Let’s just say we now know the waist size for every coach in the League,” Williams jokes. To date, Diamondback has supplied the NFL with just over 1,000 commbelt sets, and Williams reports that feedback about their effectiveness this football season has been “nothing short of positive.” He credits this success, in part, to how collaboratively his NFL contacts worked with Diamondback through the development process.

Success with those new communication belts has spring-boarded Diamondback into another new product opportunity with the NFL — this time on the instant-replay side of the game.

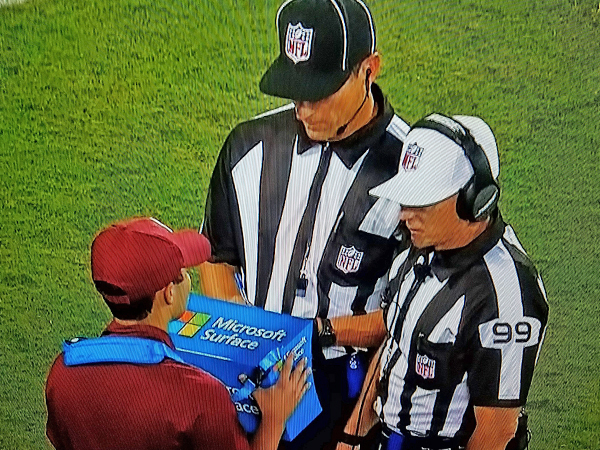

“We designed those blue Microsoft® replay cases on the sidelines, too,” Williams says. “Once we had proven ourselves as a strategic partner on the belts, they felt comfortable enough to enlist our help on a new replay system.”

Called a Mobile Replay Unit (MRU), Diamondback’s design secures and supports a Microsoft Surface tablet and related components. Each game operates with two MRUs, one at either end of the field. The innovation allows the replay screen to come to the officials rather than the officials going off the field to a centrally located screen. It speeds up the replay evaluation process considerably.

Every NFL stadium now has a “live” MRU set, plus two more MRUs as backup.

“There were a lot of nerves on the sidelines at the Hall of Fame game when we first went live,” Williams admits. “But there were also a lot of high-fives after the first replay review was under our belts!”

Diamondback is parlaying these opportunities with the NFL into college football as well. Williams says that the University of Virginia, Notre Dame, Clemson and Bowling Green are now sharing their challenges with storing and carrying tools and equipment.

“How to organize, carry and transport your tools and gear are pretty universal issues,” Williams says, “And the guys at the top of their industries are always looking for ways to improve.”

But, despite new product developments for football, Williams maintains that Diamondback’s core tool belt line will always remain firmly rooted in the construction industry — it’s the brand’s “bread and butter.”

In that regard, Diamondback is releasing a new tool belt rig this holiday season. It’s called “The Greenhorn,” with a streamlined design that’s geared toward trim work, installations or for new guys on the jobsite that don’t need to carry as many tools on their waists.

“Though it meets all our insanely high quality standards, the pared-back design allows us to hit a lower price point, which is good for those who want a second setup for quick punch list work or even some shop use,” Williams explains.

The company is also working on new specialized accessories, a steady stream of pouches and holsters to complement Diamondback’s existing belt systems and even some new gear bags that will launch in early 2018.

“These days, it seems we’re adding something new to the line every couple weeks,” Williams adds.

Juggling two wearables businesses, and feeding the sport and construction industries with new products, is more than a full-time job — especially when you may, on occasion, need to take your shift at the sewing machine, too. But Williams wouldn’t have it any other way.

“All my life, I have loved to work with my hands and make ideas a reality,” Williams says. “The opportunity to use that passion in support of men and women who do the hard work of making real and lasting things — whether carpenters, woodworkers, plumbers or whomever else — well, that’s a real honor. There’s great satisfaction and pride that comes from making the best products in the industry, right here in the USA, and without compromise.”

Learn more about Diamondback Toolbelts by clicking here.