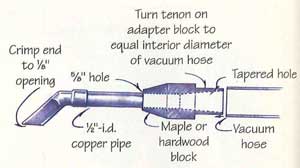

To build a crevice tool for my shop vacuum, I turned an adapter block for the hose on my lathe, then made the nozzle from copper tubing. For the adapter, start with a turning square about 6” long and a bit wider than the outside diameter of your shop-vacuum hose. Attach a faceplate to the snout end of the block and a live center to the other end. At the live-center end, turn a tenon to a diameter that fits snugly inside your hose. Chamfer the other end to form a tapered snout as shown.

Remove the live center and bore a centered hole clear through the piece that matches the outside diameter of your copper pipe. (A 5/8” hole usually works for 1/2”-i.d. Pipe, but check to be sure) To finish the block, taper the airway using a scraper, the separate the snout end from the faceplate with a parting tool.

Epoxy the copper tube into the snout end of the adapter. Use a length that suits your needs. On the end of my nozzle, I use a 45 degree elbow connector that’s crimped on the open end, but you can also use a right-angle or straight piece for different applications.

-John Summer

Silver Spring, Maryland