The last time you needed to buy a new blade for one of your saws, how did you choose it? If you found yourself staring at a rack of saw blades at the home center or a woodworking tool dealer, glazing over at the cornucopia of colors, grinds and thousands of shiny carbide teeth, it probably felt a little bewildering. There are blades these days to suit every application, material type and tool. And, prices run the gamut.

In the end, did you finally pick on based on price? Did the dizzying number of options leave you wondering if they aren’t all more or less the same in the end anyway?

If this scenario sounds familiar, you’re not alone, suggests Salo Taro, national sales manager for CMT.

“Two of the most common misconceptions I hear from tool users is that all blades have similar life, and that blade coatings are just painted-on gimmicks. But, nothing could be further from the truth.”

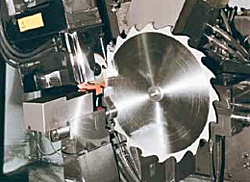

Taro spends a lot of time clearing up misinformation about blades, and with good reason: Italy-based CMT stakes its reputation on developing premium quality blades, bits and cutters for woodworkers, contractors and industrial applications, and they’ve been doing it for more than 50 years. “We’ve invested in the most advanced, most state-of-the-art technology in CNC machine equipment and software to manufacture the highest quality woodworking tools in the world. We also have the most highly skilled engineers and operators to manage our operations in Europe,” Taro adds.

Why do misconceptions about saw blades continue? Well, there’s no question that advancements in blade technology over the past 30 years or so have raised the bar of quality higher than it’s ever been. It’s harder to buy a truly awful saw blade these days, and competition between leading manufacturers is fierce. We end users reap the benefits, across quite a broad range of blade pricing. And, blades these days look similar from one manufacturer to the next. They all have carbide teeth, come in an assortment of styles to suit many tools and typically have a nifty color scheme. It only seems plausible to those outside of the blade manufacturing industry that maybe, just maybe, one blade is qualitatively pretty much like the next.

However, Taro disagrees. “There is so much research, metallurgy and engineering that goes into blade technology, and those attributes aren’t easy to see through a blade package on a shelf — if at all. You can’t tell quality based on appearance.”

But, Sal says, CMT “doesn’t cut corners” on quality. That’s why the company uses only the highest grade German steel for its blade bodies, then laser-cuts it to exact shape for perfect balance. Even the arbor holes are cut with a laser instead of punched from the steel to ensure that they are centered and will precisely fit a saw’s arbor. “We also use the finest industrial-grade micro-grain carbide for our blade teeth, to stay sharp and wear longer than our competition. Then we use a tri-metal brazing process, which provides the best resistance to shock during cutting.”

And, he confirms, the signature orange coating on a CMT blade is more than just a pretty paint job. “Our trademarked orange coating is industrial-strength PFTE or polytetrafluoroethylene to resist resin buildup, burning, rust or other corrosion. It’s a Teflon® blend that will keep your blade running cooler, cleaner and smoother over time.”

Still, there’s no debating that premium blades can be expensive. Around 2008, when the recent recession began, Sal says the company heard frequent concerns from customers who wanted blades that were more economically priced, to help satisfy the bottom-line challenges professional contractors and cabinet builders were facing at the time.

“Our Industrial Thin Kerf ITK™ blades have been very popular with the pros since we launched that brand about 15 years ago. So, about two and half years ago, we expanded the ITK line to give our customers more choices of ITK at a broader range of pricing.”

In addition to the “Industrial” version of ITK, CMT added two more blade categories: ITK Contractor and ITK Plus. The Contractor line includes some 22 different blades in sizes ranging from 3-3/8-in.-diameter up to 14-in. They feature heavy-duty German steel plates hardened to 44 on the Rockwell scale, with expansion slots and “construction grade” carbide for long life and better performance. Prices for ITK Contractor blades are about $12 to around $50 retail, and the blades are intended for daily use by contractors and remodelers looking for the best compromise between longevity and affordable pricing.

The ITK Plus line is a step up from the Contractor blades. These blades feature high-density carbide teeth, made with a new SinterHIP process that uses both high pressure and high temperature to create porous-free teeth. ITK Plus carbide purportedly provides a longer cutting life than traditional carbide. The ITK Plus blades, which have CMT’s orange nonstick coating, come in some 30 different options in 5-3/8- to 12-in. sizes. Prices range from about $15 to $76 for wood-cutting blades. Several ITK Plus blades for cutting cementitious Hardie™ Board siding are also available.

Taro says the ITK Plus blades are a great mid-price point series for general woodworking applications.

To help make it easier for end users to choose the right ITK blade to meet their needs, CMT has also added “Good, Better, Best” qualifiers on the packaging, catalog and web descriptions of these blades. Those simple distinctions represent specific attributes of each blade grouping, as well as low, medium and high pricing for ITK Contractor, Plus and Industrial blades.

“Whether you need a blade for framing, finishing, ripping or general purpose woodworking, we’ve got an ITK blade that will satisfy the quality and pricing that meets your needs,” Taro says. “We feel this expansion of the ITK line brings the absolute best value to market — and that’s always been our goal: to continually improve our quality for woodworkers, contractors and industry.”

Learn more about CMT’s blades, bits and other products by clicking here. Or, watch Taro cover each ITK blade category in more detail in a video blog we conducted at CMT’s booth at the 2013 AWFS Fair.