About 18 years ago, Charles Mak says he knew next to nothing about woodworking – except maybe a little bit about the circular saw. The tools he owned pretty much consisted of screwdrivers and tape measures.

He and his wife, however, had a hobby of going to garage sales and, at one of them, he found some old ladies selling boxes of tools for $60 total. Charles bought the tools – a circular saw, a router, a sander, some power tool accessories, etc. – and brought them home.

“I started watching Norm Abram on The New Yankee Workshop, in my opinion still the finest woodworking show,” as well as buying woodworking magazines from garage sales and, in time, Charles said, “I came to realize what those tools could do.”

Now, in 2017, he has contributed over 100 shop tips to woodworking magazines – starting with Woodworker’s Journal in 2010 – and has taught several woodworking seminars.

At first, Charles said, he built some simple shelves, and some bookcases for his daughter. “My focus was to develop skills and come up with a functional piece.”

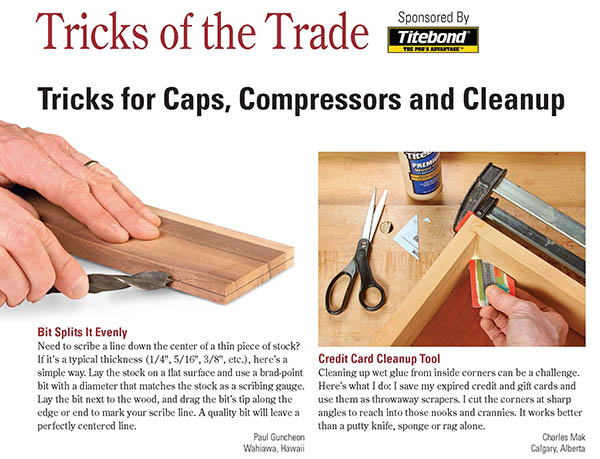

As he continued in woodworking, Charles noted, his personality as someone who enjoys solving problems meant that he also enjoyed trying to come up with shop-made solutions to woodworking issues.

He also applied his problem-solving skills to the use of tools. If he got a new tool, for example, his first step would be to read the manual. “Number one when I get a new tool is I have to know how to use it. I’ll first read all the manuals, but they’re sometimes confusing. Many manuals are poorly written.”

So, after reading the manual, Charles will put his new tool to use on scrap wood and challenge himself to see if he could clarify the instructions, or do something better – more accurately, for example – than indicated in the instructions.

For example, when he bought a new Festool Domino jointer a couple of years ago, he found the instructions “pretty fundamental” and that he could do much more with the tool than they indicated.

In 2005, Charles joined the seasonal staff at a local woodworking store near his Calgary, Alberta, home and, after the holiday season, Lee Valley Tools asked him to stay on as part-time staff. After seeing an article he had written about mechanical sculpture (“you turn a crank, and a certain movement will come up” is how Charles describes this type of project), management asked him if he would teach a class on the subject for the rest of the staff.

He did, and it also sparked the thought that “if I could teach a class for my coworkers, I could teach to others.”

Since 2006, Charles has taught about 12 seminars with six to eight participants per year. He offers around two and one-half new classes per year, mostly because “I don’t like teaching the same class over and over.” (He does repeat some, he said. “Even with the same class, you never know who’s coming to your class. Some may have never used a saw or used a lathe,” and still, “Your job is to make sure the six to eight students complete their project successfully.”)

“One of my objectives of woodworking these days is to share my passion and knowledge,” Charles said. To that end, he also makes presentations to local woodworking clubs and teaches workshops at the community education and local high school level.

Particularly with the decline in high school woodworking classes, “My intention is to tell people that don’t need to have a lot of time or money,” Charles said.

To that end, although he describes himself as a “balanced woodworker” who uses both hand and power tools, he also says he has been moving more toward hand tool use in the past few years. “I’m trying to present useful techniques,” he said.

That means that, in his projects overall, he prefers to add some kind of technique twist. For instance, Charles is currently building a cabinet to house his magazine collection. “It’s going to include sliding doors, versus just hinging the doors to the cabinet,” he said.

A fan of James Krenov’s work, Charles tries to incorporate some of Krenov’s style into some of his work – knife hinges in cabinets, for instance. His woodworking, Charles says, consists of pretty much everything except carving, and he hasn’t done chairs yet. He has, however, done woodturning, furniture, boxes, and tools – such as a turned multi-bit screwdriver project featured in the May/June 2011 issue of Woodworker’s Journal.

One of his recent projects was a speech bubble shelf, a box in the shape of a speech bubble that can be wall-mounted to display and hold objects. Charles used dovetail joints for this project and, because of the angles of the speech bubble, “the cutting and clamping was really challenging,” he said.

Mostly, Charles prefers to build his projects out of hardwood: oak or African mahogany for casework; poplar for small boxes. He only uses MDF for shop jigs.

Charles’s woodworking philosophy, which he plans to keep sharing in his writings, seminars and shop tips, is that “You don’t need a ton to do a lot of things.”