I have been chamfering smaller-diameter dowels for years, but I would like a way to do the same thing on larger dowels, up to about 2 inches in diameter. I now try and do it by hand on a belt sander, but the results are inconsistent. Please help! – Nick P.

Tim Inman: I think if you’ll check out tools for making “rustic” Teddy Roosevelt-era cabin furniture, you’ll find just the chamfering tool you’re looking for. I have one that goes with my grandfather’s hollow auger to get it started. It will do up to 2-1/2 inches. Mine fits in an old-fashioned brace, and I wouldn’t have it any other way. If you can’t find a new one, start haunting antique tool bins.

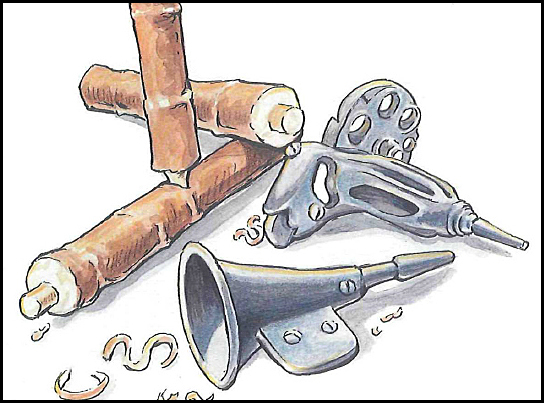

Chris Marshall: If you go online to look for the tool Tim suggests, Nick, try using either of the search terms “spoke pointer” or “dowel pointer.” Those are common parlance for these antique tools, which were made by companies like Stanley and E.C. Stearns. As I understand it, spoke pointers originally were used by wheelwrights and blacksmiths to round the ends of wooden wheel spokes before using a hollow auger to form elongated, round tenons of specific diameters (see illustration below). Dowel pointers are smaller versions of spoke pointers. The design of most of most pointers is pretty simple: they have a conical end that accepts spokes (or dowels) in a range of sizes, and there’s an adjustable cutter mounted to the cone that meets the wood at an angle. A few turns with a brace creates a chamfer, which then would allow the spoke to fit into the opening of a hollow auger for additional stock removal. More turns of the brace, though, could shave the wood all the way to a point. Think of pointers like oversized pencil sharpeners.

These days, there are tenon-cutting tools for creating round tenons on the ends of large branches, small logs and the like for making rustic furniture (see top photo). You chuck them in a power drill instead of a brace. Their design is similar to vintage pointers, and they would probably work for your purposes if you stop the action quickly to only cut a chamfer and not the tenon. But, they’re expensive. Scrounging old-tool web sites, eBay and antique stores for an actual spoke pointer will be the more affordable way to go.

One other option does come to mind: Have you considered chucking your dowels between centers on a lathe, spindle style, and cutting chamfers that way? The challenge would be to get the already round dowels perfectly centered on the lathe, but there are inexpensive center-finding tools like the one shown below to help make the task easier. Then, once the dowel is mounted, you could form the chamfer with a scraper held against the tool rest. Simple. The diameter of the dowel wouldn’t matter, either, giving you the versatility you need. If you have a lathe with a bed long enough to fit your dowel lengths, it’d at least be worth a try.

Maybe other eZine readers can offer their own methods for quick, easy dowel chamfering on larger dowel diameters.