Tricks of the Trade

-

Clean Cuts on Rough Grain

If you’re having a problem getting a clean cut surface on a particularly difficult grain area on a turning project, take the lightest cut possible with the sharpest gouge you can hone.

-

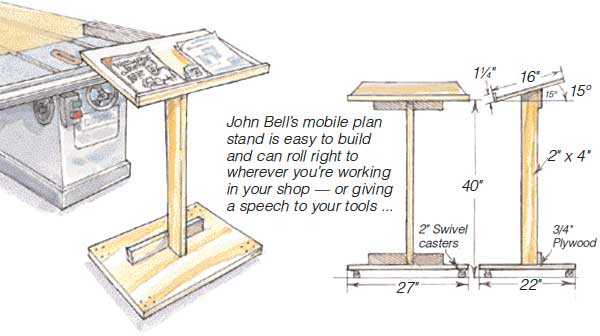

Mobile Plan Stand

I built this small mobile lectern for my shop because I got tired of constantly walking back and forth to double-check the dimensions on my projects.

-

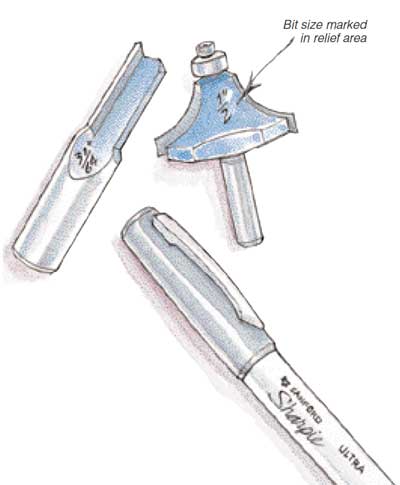

Marking Router Bits

I’ve recently taken to marking my router bits with a Sharpie fine-point permanent marker.

-

Mark Your Router Base for Concentricity

In order for a router to cut a straight line, the bit has to remain a fixed distance away from the edge of the router base and whatever you’re using as a clamped straightedge.

-

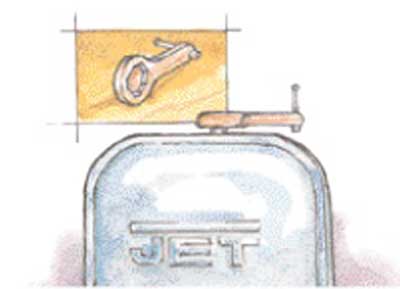

Tensioning the Band Saw

The usual band saw tensioning devices are not only awkward to use but have no reference point.

-

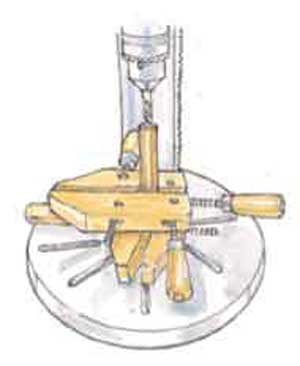

Drilling Holes in Dowel Ends

Drilling holes in the ends of dowel rods is awkward because they’re hard to clamp vertically.

-

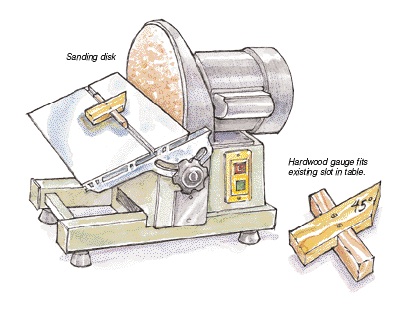

Improved Disk Sander

The one shortcoming of my disk sander is the sloppy miter gauge that came with it.

-

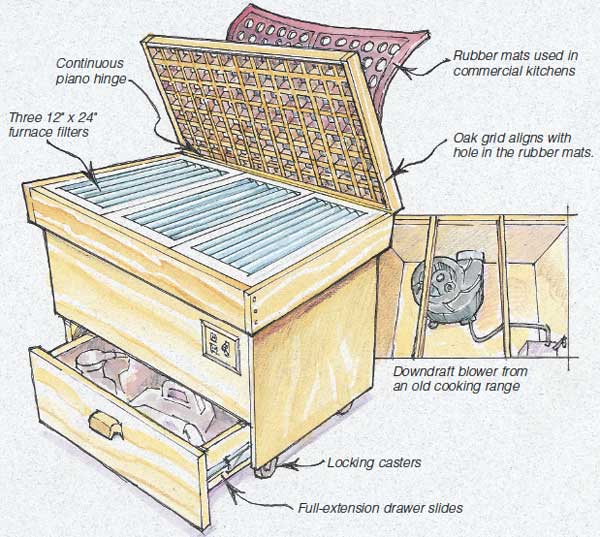

Downdraft Table

I used a downdraft blower from an old Sears cook range to help make this downdraft sanding table.

-

All-in-One Air Station

Even though my basement shop is small, my nailing tools and supplies were still scattered here and there all over the shop.

-

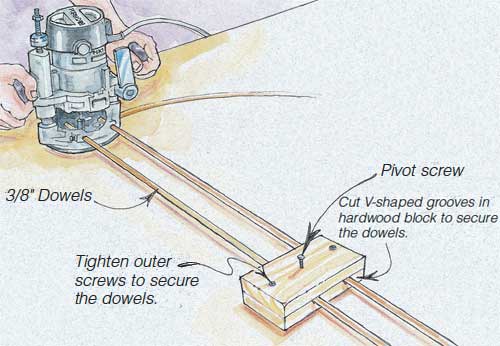

Jig for Large Radius Routing

Rather than spend the money on a specialized routing attachment, I improvised and used two 36″ hardwood dowels fitted into the holes in the baseplate of my router.