Tricks of the Trade

-

Clamping Your Small Parts

When gluing a small odd-shaped part, it’s often a challenge to figure out how best to clamp it.

-

Boxes without Spacers

When making small boxes, many woodworkers find it’s easiest to first assemble the box, and then cut off the lid by making four ripping cuts.

-

Lining Your Drawers

It can be difficult to get a good fit when cutting velvet, velour, or felt to use as a lining for the plywood bottom of a drawer.

-

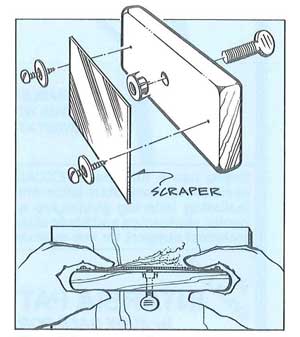

Hand Scraper Jig

If you have a lot of scraping to do, flexing the steel will likely result in some dog-tired fingers.

-

Color Code Your Drill Bits

Drill bit manufacturers usually stamp the diameter of the bit on the upper part of the shank, but after a while the drill chuck wears the numbers off.

-

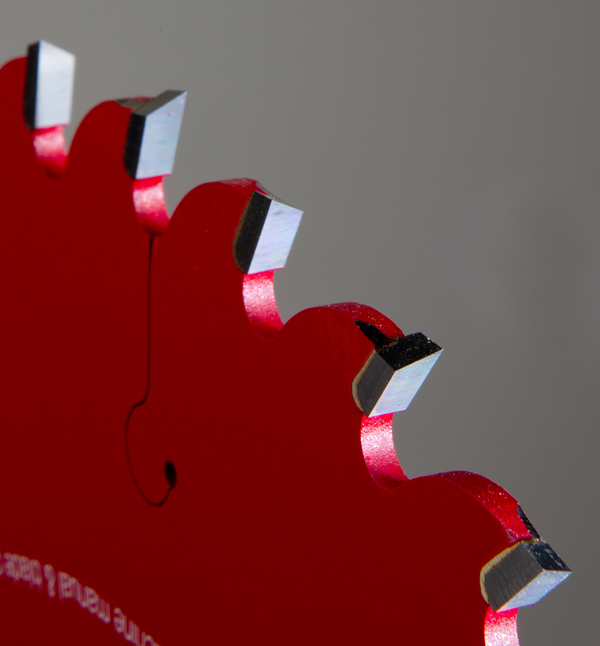

Protecting Your Teeth

I’ve used the plastic protectors that come with some of them, however they usually break apart after a while.

-

Gadgets for Spreading Glue

My favorite gadget for applying glue is made from a cheap plastic spreader for auto body filler.

-

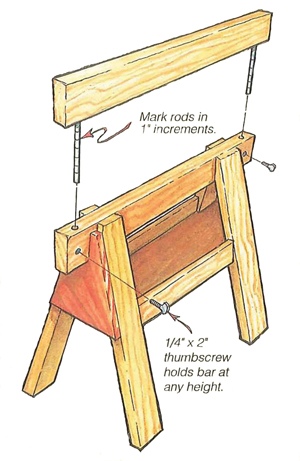

A Sawhorse Addition

There were many times when I wished sawhorses were a little higher, or even a lot higher.

-

The Perfect Label

I’ve finally found a product that sticks to almost anything, can be removed easily and is inexpensive.

-

Short Rulers

I’ve always had problems making measurements at my lathe when working on a spindle less than four or five inches long.