You hear about woodworking niches. Casey Schillinger’s is very specific. His company, Heritage Clothespins, makes wooden clothespins for hanging laundry to dry.

Back when he started woodworking a few years ago, Casey worked with his wife’s uncle – and some wood from Bradford Forest, the Pennsylvania lumberyard where his wife was employed at the time – to make some pieces for the church where he worked. One was a small candy stand for the youth group; another a wooden cross.

“The first project I did mostly on my own was a shoeshine box for my father-in-law,” Casey said.

For some time, Casey had also wanted to start his own business. “I wanted to teach that to my kids, as a really valuable skill. I wanted to do it myself, so I could teach them.” In searching for his business opportunities, however, Casey “didn’t want to just make something and put it on the shelf for somebody to look at. I wanted to make something useful.”

A long-time reader of The Deliberate Agrarian blog, Casey noticed that site owner Herrick Kimball had started selling things on the side and purchased a plans book that taught him to make wooden clothespins.

Now living in Texas, where he works full-time for an oil and gas company, Casey spends his evenings and weekends making wooden clothespins.

“All the clothespins you can find in the big box store are poorly made from cheap material,” Casey said. “They are not made to last, but the ones I make are. Most of the store-bought ones are small, have weak springs and are not made of hardwood. People who hang their clothes on a line are tired of purchasing clothespins that do not do the job and do not last long.”

The clothespins Casey makes are hardwood, with stainless steel springs, and are double the size of those sold in stores. Most of those he sells are made from ash, and used for hanging clothes on the line, although he also has some available in cherry and walnut that might be used in the kitchen to hold chip bags closed, for example. Cherry and walnut clothespins, Casey said, “you don’t want to use outside because the tannins in them could stain your clothes. Ash doesn’t.”

When creating the clothespins, “The tolerance is quite tight for some of the different parts,” Casey said. “I use a caliper quite a bit.”

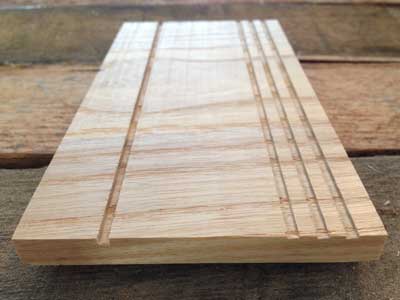

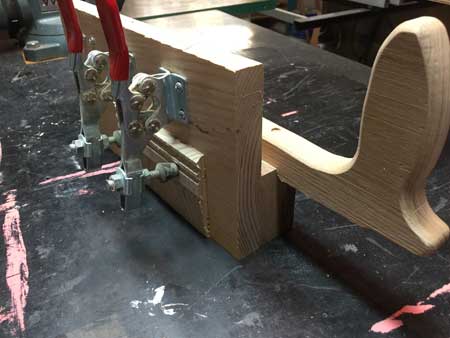

He starts with a rectangle of wood measuring 3-1/2 inches x 6 inches, then cuts it into slices on the table saw. The table saw is also how he cuts the clothespins’ three grip grooves and spring clip groove. He then uses a shaper to round out grooves and create the front angle. A jig mounted on the table saw creates the internal angles. “Every clothespin is put together by hand,” Casey said.

Eventually, if they’re interested, Casey said, his kids (he currently has one daughter and another child on the way) might take over the clothespins business – and potential future business ideas. “Right now, all the money I make from this is going to my daughter’s college account,” he said, “so the idea is, she could take it over.”