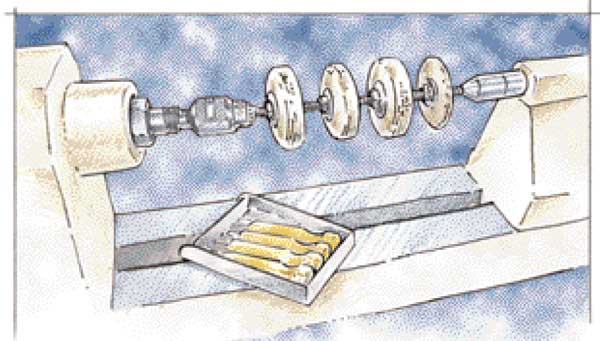

The variously shaped profiles of my woodcarving chisel blades require a variety of strops, and I used to have to mount them one at a time in my lathe, switching from one to the next. My fix was to mount them all on a length of 5/8″ threaded rod with pairs of washers and nuts fixing each strop in place. I filed off an inch of threads on one end of the rod so I could clamp it in a drill chuck on the headstock. I drilled a small, centered dimple in the other end to fit the tip of a cone center mounted in the tailstock to capture the rod securely. I run the lathe in reverse so the strops spin away from the tool blades. With the lathe dialed down to 600 rpm, I can hone my chisels quickly and without any changeovers.

– Willard Anderson

Chapel Hill, North Carolina