When building cabinets, I frequently assemble my stacked dado blade to cut a “near” three-quarter-inch dado. At this point, I can no longer use the arbor washer that came with my saw and still have all threads in the arbor nut engage. The big question is: is it safe to secure a blade without using a washer? I’ve observed that without the arbor nut washer, I must hold the outer blade securely while tightening the nut to prevent the blade from turning and possibly contacting the teeth of the adjacent chipper blade. – Dave Zempel

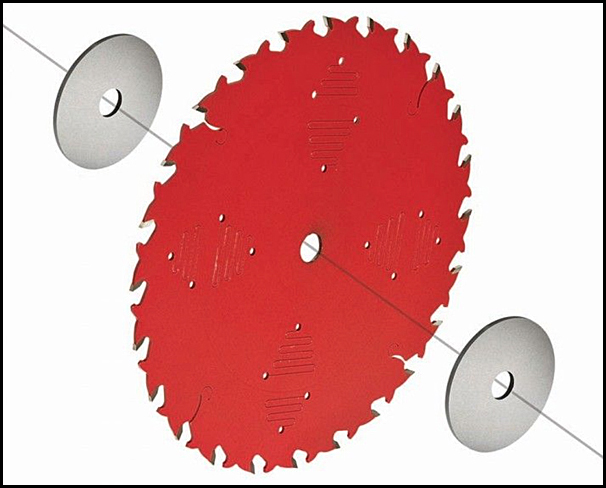

Rod Burrow: Seems like you are maxing out the dado capacity of the saw, which has a short arbor shaft. Most saws today have a maximum dado capacity 13/16 in. If a new saw isn’t on your holiday list this year, then I suggest you use a single blade stabilizer. Blade stabilizers are usually thinner than original equipment arbor washers and should allow the arbor nut to fit securely. Use both if your inner washer is not milled in the arbor. Not having an outer arbor washer could allow the stack to slip and the carbides to collide. Or, here’s another simply solution to the problem: set your dado to 3/8 in. or 1/2 in. instead and make two plow cuts to reach the 3/4-in. width you’re after. This will reduce some of the heat on the carbide teeth as well as stress on your saw’s motor!

Rod Burrow is quality assurance/customer service manager at RIKON Tools.

Chris Marshall: If you take Rod’s advice and purchase a set of blade stabilizers, they’ll serve the added duty of stiffening thin-kerf saw blades. Thin-kerf blades are helpful for lighter-duty saws because the motor doesn’t have to work as hard to drive the blade teeth through what’s being cut. But, they can deflect during cutting — especially on those demanding cuts through thick material or in boards that have internal stresses. Stabilizers will stiffen the blade to make sure your cuts remain flat and square. So, two benefits from one saw accessory. The only downside though, is that stabilizers behave like oversized washers, reducing the cutting capacity of the blade to some extent.

Tim Inman: I’m with Rod on this one. Pulling a dado head involves a lot of resistance beyond the ordinary resistance you might expect from a simple single-saw kerf from a common blade. So having a very secure setup on your saw’s arbor is paramount. I wouldn’t allow for any “half nut” threads or lack of stiffening washers, etc. Set that dado head up exactly as it was intended. I’ll add this to Rod’s answer: When I was a kid (cheap help for my dad and his brother who built custom cabinets and staircases, etc. for a living) we did “double runs” on dadoes many times. We usually set the dado head up for a 1/2-in.-wide cut. Then we made two passes over the dado to get the 3/4-in.-wide dado or plow cut we needed by realigning the rip fence to get the correct dimension in the groove. Why did we set up the 1/2-in. dado? It was just easier to set up the 1/2-in. set on the dado head we had. The little bit of overlap didn’t hurt a thing, and we ended up in the same place in the end: a perfect fit for our boards and a nice clean groove cut to hold them.