Chris Marshall: If you keep your carbide-tipped saw blades and router bits clean, and use them for the purposes for which they are intended, they should retain sharp edges for a very long time. But, carbide is brittle, and eventually it will get dull. While a diamond hone is hard enough to refresh a carbide edge, my answer is still no to your question. I don’t think most of us (myself included here!) have the skills to sharpen our own carbide cutting tools well. Our bits and blades cut effectively because of a complex relationship between several different tooth grinds (face, side, top, etc.) and a balance of close tolerances from one tooth to the next. If one tooth is sharpened differently from those around it, it won’t bear the same cutting loads as other teeth, causing them to work harder and dull faster. On router bits, incorrect sharpening can also change the cutting profile of the bit.

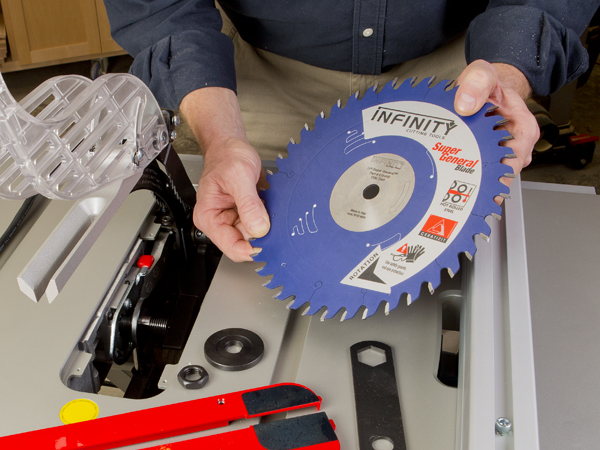

When the time comes, send your dull bits and blades to a certified blade sharpener and let their machinists and grinding machines restore them to factory sharp again. It isn’t that expensive for bits and blades that are otherwise in good shape (flat blade body, straight shank, cutting edges unchipped) but just dull. For instance, you should be able to get a general purpose 10-in. table saw blade sharpened for around $25 plus the cost of shipping. And, the blade manufacturer will often provide sharpening-service recommendations for their blades and bits (check their website). I really think we should leave this job to the pros. It’s the best way to extend the life of your cutting tool investments and keep them performing like new.