About three weeks ago, members of our staff attended the Association of Woodworking & Furnishings Suppliers (AWFS) Fair in Las Vegas — it’s one of the largest trade shows for our industry and a great opportunity to see what manufacturers are up to these days. I never miss it. But for me, the highlight of that four-day press junket was watching two young people compete against one another in a three-day, 21-hour cabinetmaking contest happening live at the show. The contest was called the WorldSkills Cabinetmaking Qualifying Trial, and the winner’s prize was a trip to Leipzig, Germany, in 2013 to compete internationally as a WorldSkills Cabinetmaking finalist.

I caught up with the event on the final day of competition. The Trial’s project was a small but intricate nightstand. While the two competitors each worked on it, I tried to put myself in their shoes. If you think that old adage about “measuring twice and cutting once” is important when you’re working alone, just imagine how much concentration it would take to build a complex woodworking project “on the clock” under the watchful eye of three judges and a trade show’s worth of spectators wandering by. Then there was me snapping photos just a few feet from their workbenches.

That’s what Kaydee Walters, a 2011 graduate of Tooele High School in Tooele, Utah, and Daniel Berrios, a graduate of Bethlehem Vo-Tech School in Bethlehem, Pennsylvania, were up against. But, these kids had woodworking “chops” to be sure — both are Gold Medalists in High School Cabinetmaking through an organization called SkillsUSA. It’s a national program serving high school and post-secondary students who are preparing for some 90 different trade careers. Through chapters organized in participating schools, SkillsUSA teaches leadership skills, teamwork, citizenship and character development. Both Kaydee and Daniel have won previous cabinetmaking competitions at their respective district and state competitions, then at the national level. Daniel won nationals in 2010, and Kaydee nabbed that victory this past June. Those competitions qualified them for the AWFS challenge.

I spoke with Robert Tobias, an associate professor of Cabinetmaking and Wood Technology at Thaddeus Stevens College of Technology in Lancaster, Pennsylvania. Rob was one of three technical experts who were overseeing the three-day challenge as well as judging the competitor projects. Part of Rob’s role for SkillsUSA is also to help prepare competitors for the WorldSkills competition in 2013 as well as coach them there. Rob admitted that he developed the initial plans for the nightstand project Kaydee and Daniel were building.

“I also helped organize this WordSkills Cabinetmaking Qualifying Trial, and it’s the first year AWFS has hosted it. But, it required a great team effort to put this all together, which included Adria Torrez, AWFS’s Education Manager for the event, and Ada Kranenberg, who coordinates the SkillsUSA Worldteam. Charles Wilson (Charles Wilson Millworks, Cedar City, Utah) and Saul Martin (shop superintendent of Architectural Woodworking Company, Monterey Park, California) were my fellow competition judges. I also need to thank Kent Gilchrist, who chairs a technical committee that helps develop the SkillsUSA district, state and national competitions through the Architectural Woodwork Institute.”

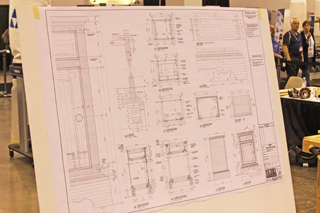

I was impressed by the complexity of the cherry nightstand. It seemed an elegant but demanding amalgamation of joinery styles, millwork exercises and casework details. A copy of the project plans was on display for spectators to study.

Rob explained that, according to rules established by the WorldSkills organization, the Cabinetmaking Qualifying Trial project was required to have a hand-dovetailed drawer, some veneer work and a door. It also needed to be build-able in a 21-hour time time frame, over three seven-hour workdays. Rob based it loosely on a plan he’s used for college courses at Thaddeus Stevens, but the final design changed significantly to satisfy guidelines set forth by WorldSkills. “There were other project suggestions besides mine. All of the submissions were presented to a technical expert forum six months before the AWFS competition. Our forum voted on the top three submitted plans, and then mine was selected at random from those three one month before the competition. Saul Martin took my original design and turned it into excellent CAD renderings.”

Daniel and Kaydee received the preliminary nightstand plans three weeks prior to AWFS so they would have a chance to study the drawings. But, in order to ensure transparency and fairness, which Rob says are adamant priorities of WorldSkills competition, a few days before AWFS the plans were modified another 30 percent by half of the members of the technical expert forum. These final changes would make the nightstand project unique to the two finalists going into the competition. “It guarantees that neither competitor could actually practice building it ahead of time.”

Once the competition was underway, Rob and his fellow judges evaluated the projects at various stages of construction, using a point distribution system established by WorldSkills that mirrors the evaluation methods followed at the international competition. “About half the points were based on our subjective judging and the other half were awarded for objective criteria. An example of ‘subjective’ was the condition of the drawer joints before gluing. We three judges individually scored the drawer dovetails on a scale of 1 to 10 based on quality. We averaged our scores and awarded that percentage of points to each competitor. In terms of objective points, we were measuring various identified and agreed-upon aspects of the project in an ongoing way. We also awarded points for other aspects, such as conformity to the drawings, not using extra lumber to recreate parts to correct mistakes and points for completing stages of the project on a given day. For instance, points for door and drawer layout were awarded on the first day; dovetail and door joint layouts were given on the second day.”

Looking around the competition “shop,” it was clear that the AWFS WorldSkills Cabinetmaking Trials were generously supported by tool and supply donations from a number of manufacturers at AWFS. They included: Amana Tool Corporation (router bits); Bessey Tools North America (clamps); Bosch Power Tools & Accessories (trim routers); Colonial Saw Company (Lamello biscuit joiners); Delta Power Equipment (Unisaws and dust collection); Dixon Enterprises Inc.; Festool USA (Kapex miter saws with dust extractors and stands, Domino joiners, sanders, routers and drills); Freeman; General International (Edge sander and band saw); Grex Power Tools; Joos USA, Inc. (veneer press); Kreg Tool Company (router table with beaded face frame setup); Powermatic (jointer and mortising machine); Rockler Woodworking and Hardware (workbenches, glue and other supplies); Royal Plywood (sheet materials); Senco (pin nailers, staplers and compressors); and Woodcraft.

Aside from these donations, Kaydee and Daniel were allowed to bring personal tools as well. Judges inspected their toolboxes prior to competition to make sure there would be no tools or jigs that could present an unfair advantage. “Contributing manufacturers also gave the competitors technical instruction about the proper use and safety of their tools,” Rob says.

When the competition ended and final points were tallied, Daniel edged ahead of Kaydee to win the AWFS Trials and move on to the WorldSkills international competition. In addition to that honor, he received a Delta Unisaw, Lamello biscuit joiner, Festool drill, Bessey clamps, a Bosch router and a selection of Amana router bits. His school was given a Delta Unisaw and the Powermatic jointer and mortiser from the event. As runner-up, Kaydee received a Woodcraft Pinnacle workbench, Festool drill, Bessey clamps, a Bosch router, Grex pin nailer and a selection of Amana router bits. Thaddeus Stevens College received the Kreg router table and face frame system from the competition.

In the afterglow, Kaydee says she found the AWFS competition both physically and mentally challenging. “I did things I had never done before, like hand-cut dovetails and veneering. But overall, I did my best and I really enjoyed the competition.” She is enrolled at the Utah Valley University this fall in the cabinetmaking and architectural woodworking program. Daniel will be transferring from Northampton Community College, where he’s studying CAD, to another institution to pursue a bachelor’s degree in education.

Meanwhile, Rob says Daniel has an Olympic-class event to look forward to in Leipzig, and he hopes to accompany Berrios as a coach. More than 800 students from 52 countries will be competing in 40 different skill areas. The cabinetmaking competition will consist of 25 builders, and Rob reports that it will be “very competitive internationally,” with gold, silver and bronze medals awarded to the winners. But aside from the benefits of competing at this level, Rob feels one of the greatest assets of WorldSkills is the way it promotes the value of skilled trades.

“We need to attract more young people into the trades in this country and put our skilled craftspeople on a higher pedestal as other countries do. The SkillsUSA and WorldSkills competitions are huge events nationally and worldwide … and that sends a message that this is something worth being a part of. Students can compete for the chance to represent the United States at a world competition. Who wouldn’t want to be involved? What an opportunity!”