One of the most useful, versatile and inexpensive items, which should be in every toolbox, is the ordinary cabinet scraper. Few are aware of how to use this workhorse correctly, and even more do not know how to sharpen it. I would like to share how to make this ancient tool perform magic in situations where much more expensive tools struggle.

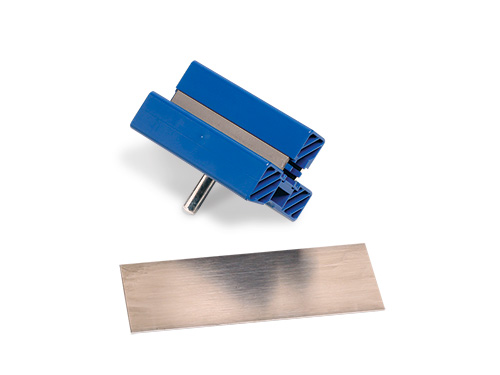

As you can see in the photo at the top of this page, cabinet scrapers come in a variety of shapes. They are often sold in a set of three to cover a variety of scraping tasks. This set, made by Crown Hand Tools in Sheffield England, a rectangular cabinet scraper (often called a card scraper), one with inside and outside radii at each end and a French curve. The card scraper is used on flat surfaces.

The edges of the middle scraper can also be used on flat surfaces while the ends will fair and smooth concave and convex surfaces. Some part of the French curve will generally shape and smooth complex shapes and often saves the day. The set from Rockler costs a mere $21.

While chisels and plane blades are tempered to a hardness on the Rockwell C Scale (HRC) of 58 to 64, a cabinet scraper wants less temper, so they are generally delivered at HRC 50 to 55. The lower temper is necessary to allow burnishing that creates a sharp burr at the edge. Burnishing is both a tool and a process. A burnisher is a round rod with a handle that is a bit like a file without any teeth. In fact, it is delivered with a polished surface and is HRC 64 or higher.

Sharpening a Scraper

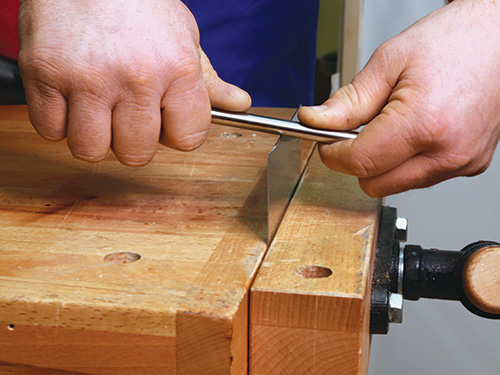

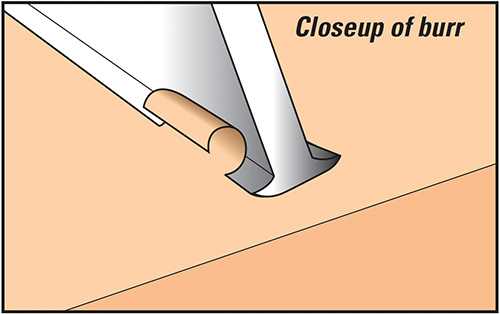

The process of sharpening a scraper in my “More on the Web” video that supports this article. In a nutshell, the process involves filing and honing the scraper’s edge square and smooth, then using the burnisher to distort the steel into a tiny burr that curls over the face of the scraper. It’s not particularly difficult, but it does require practice.

To prepare a scraper for burnishing, the work-hardened area is first removed with a mill file. This will be followed by a whetstone to smooth away file marks.

The result of over-burnishing by pushing down too hard or taking too many strokes is a ragged edge rather than a continuous sharp one.

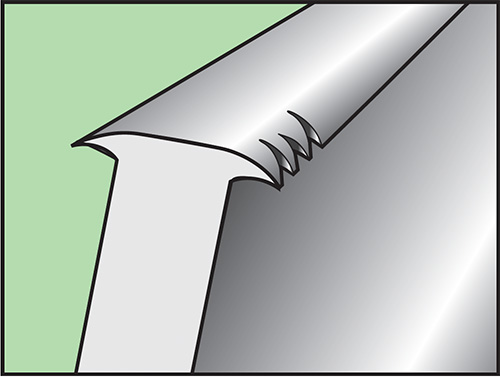

Once the edge is filed and stoned smooth and square, a burnisher is sloped 5 to 15 degrees downward from the edge and drawn across the corner of the scraper to form a sharp burr. Definite pressure is necessary. Do not make the burr too big or it will split into segments at the burr’s point. You may turn burrs on both corners of an edge.

The process work-hardens the edge, so it cannot be repeated without using a file to remove the workhardened area. The edge is then refined with a fine stone to form perfect corners. Back to the burnisher to create a new burr again.

Cabinet scrapers have a wide variety of uses — removing depressions or torn-out grain, flattening misaligned joints, cleaning off dried glue or removing old finishes. So much utility from a small piece of steel!

Until 1943, Stanley made the #112 Scraping Plane. It’s a scraper on steroids with a much heavier blade that does not cramp your hands.

Using a Cabinet Scraper

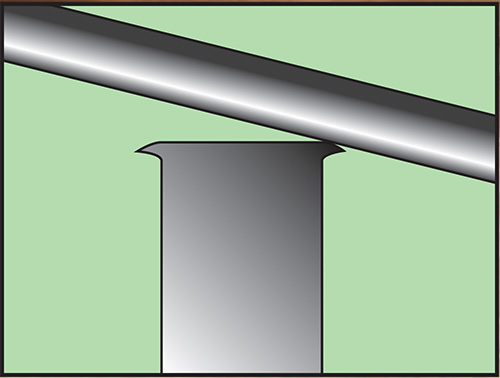

Once sharp, the scraper is held in both hands with thumbs flexing it into a gentle arch and tilting the tool slightly forward. The burr is engaged against the surface of the wood and pushed to scrape tiny, fine curls. Holders for card scrapers, which put a slight side-to-side bend in them with a handle at each edge, can make using a cabinet scraper much less tiring on your hands.

A scraper used with skill can cut through tiny depressions or torn-out grain without leaving marks. It can cut with or against the grain with equal verve and is handy for flattening uneven joints or removing dried glue residue.

When you need to get into areas that planes or sanders will not reach, here’s the tool for the job. It is also the best tool for stripping off an old finish. I use a card scraper every winter to scrape wax from my cross-country skis. You can’t beat the price-to-utility ratio of this simple, handy tool!