I have to admit that it is rare to hear a woodworker credit his time in a butcher shop for his precision and attention to detail in the woodshop, but that’s exactly what Bob Gasperetti did when I asked him about his early influences.

“My first brush with woodworking came at a very young age,” Bob recounted. “I grew up on Long Island and my dad commuted to Manhattan. His therapy was to putter in a basement workshop. Being the only son in an Italian family, I got to go downstairs and putter while my sisters washed the dishes. My father passed away when I was 11, so I inherited the workshop, took woodworking in high school, and even sold a few pieces in my teens.

“However, between the ages of 16 and 24, I worked in a very high-priced gourmet butcher shop. This may seem unconnected to woodworking, but in fact, I give my boss from there a lot of credit for the caliber of work I do now. Think of a roast beef that you might see on the cover of a food magazine. It will look perfect, with all the gristle removed, the tie strings perfectly and evenly spaced, and so on. That’s the sort of things we did in that butcher shop. From that shop I developed an attention to detail, and the habit of using the best ingredients.

“Off and on, I also bummed around and headed out West while I tried to figure out what I wanted to do with my life. I could not see myself working for someone else, and I wanted to work with my hands. Naturally, I thought about doing woodworking, but was advised against it by a doctor because of a hearing deficiency. However, I realized there are ways to protect your ears: I started wearing ear muffs long before most wood suppliers sold them, and I am glad to say my hearing has not gotten any worse.

“I went to college and finished my bachelor’s degree in industrial arts education, moved to Vermont in 1979 and started teaching woodworking and drafting at a private high school. Because it was a private school, there was no taxpayer oversight, so I was allowed to use the shop as if it were my own, and I did that to jumpstart my business. I lasted there four years before I went out on my own.

“My first shop was a girlfriend’s garage, and my first job was subcontracting hand-cut dovetails for another cabinetmaker. That got me into my own shop, which I set up in an old rented barn. Four years later, I bought an 1850’s village home with an attached horse barn, and converted it to a shop. My office doubled as a bathroom, and the horse barn was my showroom. I’ve since graduated to a shop built onto the property next to my home, where I work along with one helper.

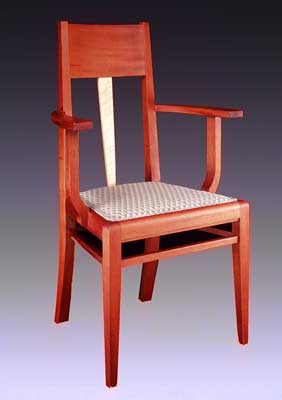

“I build what I would call a blend of Shaker and Arts and Crafts inspired furniture, which to me means beautiful wood in functional furniture that has been put together correctly, with traditional joinery. The piece that got me started professionally was a cherry blanket chest with a cedar bottom, and it appears in the logo on my T-shirt.”

When I asked about some of his favorite pieces, he replied, “My favorite piece is whatever I am working on at the time. I get a real thrill out of attacking a stack of roughsawn lumber and turning it into something beautiful. Most everything I build is made to order and customized for the customer.” Still, he did have some interesting comments about a few of his works.

“I made the Walnut Armoire with the figured wood doors for the guy from whom I buy my wood,” he told me. “Because I don’t use plywood or veneers, the Sleigh Bed is actually coopered from solid wood slats.

“Over the years, I made a number of rocking chairs, but was never happy with the way they rocked. They either creaked or did not rock smoothly. The hardest part about making a rocking chair is the rocker, to get it so that when you push it with no one in it, the chair will keep rocking smoothly until it comes to a non-jerking halt. That tells you how it will rock with someone in it. Normally I avoid prototypes, but for the rocker, my helper and I did them in order to get just what I wanted, and the upshot is that I like the Vermont Rocker. It’s comfortable, sits at just the right pitch, works for all heights of people and rocks perfectly.

“One of the most fun parts of my business is making things from people’s own cherished trees. Often people have a tree that had to come down, or was blown down in a storm. When they contact me about working with their trees, I advise them how to process the log, or if they prefer, I make the arrangements for them to have it processed. I’ve made beds, tables, chests and desks from clients’ own logs along with bowls, mirrors, lamps, boxes and clocks from small pieces. I do the same for myself. The living room floor and kitchen island in my house are made from trees that needed to be taken down to put up an addition on our house.

“Not long ago, a woman called who had a birch tree removed and cut up into firewood before she realized it had fabulous curly grain. I took the firewood and am using it to make small items, like turned bowls, picture frames and serving trays. It’s spectacular wood, and if you take a beautiful piece of wood and treat it correctly, it doesn’t need much more.”

Still, it’s a long way from fancy meat to the fine lines of his furniture. When I questioned him about it, he admitted there were other influences as well, and named one in particular.

“I had a design professor who taught me that small details make the difference,” Bob explained. “There’s a huge difference, for instance, between a three thirty-seconds chamfer and an eighth-inch chamfer. You need to have an eye for proportion and balance, and that is what he taught me.”

Apparently, he taught him well.