What does it take to move a company forward — not only for the next few years but even the next few centuries? Well, for Carey Smith, founder of Big Ass Fans, it involves more than hot air from the head office and a mission statement propped up on outdated business practices. Smith knows a great deal about the downside to hot air — both literally and figuratively. He’s spent the past 16 years combatting it, by growing a company that builds state-of-the-art ceiling fans and LED lighting fixtures in Lexington, Kentucky. But making great products is only part of the equation for Smith. Also key to long-term growth is a top-down commitment to people — whether they are customers, employees, students or suppliers. It’s a business model that Smith hopes will guide Big Ass Solutions through its 200th anniversary and beyond.

It all started with a simple problem: how to make cooling products better. In 1999, Carey was selling sprinkler systems for cooling the roofs of industrial buildings, and thousands of site visits to his customers uncovered another problem. Ceiling-mounted fans were notoriously inefficient. Could they be fundamentally redesigned and made better? He thought so: by reshaping the blades using airplane airfoil technology, increasing the blade size but slowing them down and driving them with more efficient motors. It was a venture that prompted him to sell the sprinkler business and devote his energies full-time to ceiling fans.

“Carey is relentlessly focused on problem-solving,” says Katheran Wasson, Big Ass’s public relations manager. So is the company’s team of engineers and product developers. Since Big Ass’s inception, the product line has bloomed into families of industrial, commercial and residential fans that range in size from a 24-ft.-diameter Powerfoil® model down to the 18-in. directional Sweat Bee™ fan. Most of the fans are built in Lexington, and the company’s key suppliers are within a half-day’s drive. That fosters partnerships and faster response time.

Research and development happens in Big Ass’s LEED Gold certified, 44,000-square-foot laboratory. It was built in 2009, and Wasson says it’s the only facility in the country designed to run advanced air movement testing on large-diameter fans. Within this building, the company is heavily invested in its R&D: nearly nine percent of Big Ass Solutions’ annual revenue is dedicated to new product development, and that’s more than twice the industry average. A think-tank style division has even been created to explore technologies that don’t exist today.

“The layout (in the R&D facility) is so flexible that we regularly build full-size models of environments for our fans. We’ve simulated warehouses, bedrooms and even classrooms.”

Just two years ago, Big Ass Fans branched out into LED lighting and expanded the scope of its corporate identity to Big Ass Solutions. Wasson says the opportunity to move in that direction was customer-driven. The company often heard complaints from its industrial fan clientele that typical warehouse lighting is prone to dimming and short lived. So, Big Ass used its engineering expertise to combine efficient LED technology with a specially designed fixture suitable for warehouses and manufacturing centers. And, as it turned out, customers who saw those fixtures at work wanted them at home, too. “We listened and developed an industrial-strength LED for the ceiling lights common in garages and workshops,” Wasson says.

Called The Garage Light, the product’s frame is constructed from a solid piece of extruded aluminum with ribbed fins to help dissipate heat. Excess heat can otherwise shorten the lifespan of LEDs. Its patent-pending lumen maintenance trays allow for easy cleaning and maintenance. The company predicts that this light will maintain 70 percent of its initial light output for 150,000 hours, or about 70 years of in-use time at six hours per day.

Aside from a commitment to create game-changing fan and lighting products, Wasson reports that Big Ass Solutions is also devoted to its more than 600 employees — both in Lexington and in an Asian facility that makes products for just that market. During the recent recession, for instance, Big Ass Solutions retained all of its employees and hired more. Millions were also invested to build the new R&D lab. Wasson reports that the company goes to great lengths to keep employees contented: it pays wages that exceed the national average by 30 percent, offers comprehensive benefits and encourages staffers to cross-train by changing jobs within the company. It’s a proactive effort to prevent workplace boredom and burnout. “Our philosophy is that rotating between different departments will teach employees about the company as a whole and help everyone work better together.”

Philanthropy is fostered, too. Last year, Big Ass Solutions launched an annual $5,000 scholarship program for Kentucky-area graduating high school seniors who plan to attend a four-year college or university. The scholarships also provide a mentor-guided and paid internship the summer after graduation, Wasson says.

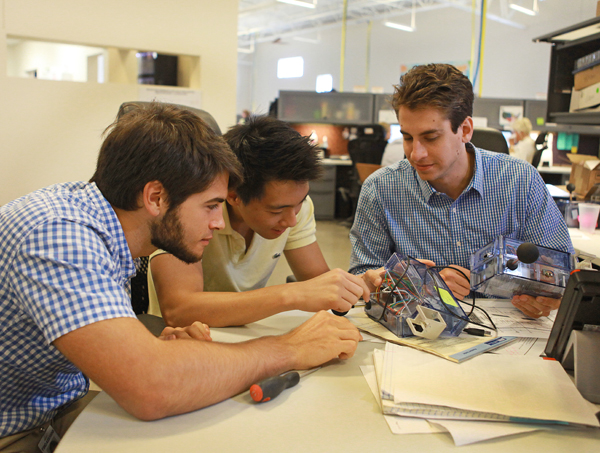

The company is committed to providing other “meaningful” and paid internships as well. Typically, 60 percent of Big Ass interns are hired by the company upon completion of their education.

Big Ass also sponsors a University Giving Program that infuses product donations and expertise into innovative architecture and design programs. Students work directly with the company’s application engineers to help solve design problems. The intent, Wasson says, is to help create a generation of professionals who will be focused on innovative and efficient problem-solving products.

“We were motivated by stories we heard about ‘brain drain’ — the top students leaving the area because they didn’t believe there were exciting professional opportunities locally … there are jobs for innovative and talented graduates.”

Even outside of its efforts to encourage today’s employees and tomorrow’s problem-solvers, Big Ass Solutions gives back to those in need. This past holiday season, the company purchased and donated nearly $25,000 worth of toys to the Lexington Fraternal Order of Firefighters. Employees raised the funds through volunteer events, and Smith matched their donations. Then staffers selected the toys to be donated.

Big Ass Solutions’ forward-focused and people-inclusive culture is driving how it does business, and the equation is working. Annual revenue has more than quadrupled since 2009, and so has its workforce. Those indicators, Carey Smith hopes, are setting the company on a course that will guide it well beyond his lifetime. The intention, quite literally, is 200 years.

“There’s a value in making products designed to last instead of being replaced, in guaranteeing job security and in our commitment to safety and durability,” Wasson says. “It may seem old-fashioned, but we pair those values with innovative technology, and that bucks the current trend in American business. That impresses our customers and our employees … We see sustainability very pragmatically: if you spend so much time and energy creating something — whether it’s a product or a company — why wouldn’t you build it to last?”

To learn more about Big Ass Solutions, click here.