This problem has plagued me for years. I am fed up. I do a lot of sanding and try to buy the best components to help me achieve beautiful finishes. Problem (this happens only with random-orbit type sanders): the backing pad (which I’ll call Side A) onto which the sandpaper discs with Velcro® (Side B) sticks fails very often. They are expensive, at $20-plus each, to fail so often.

I thought that, because I was taking the different grit sandpaper discs (Side B) off and on to change from lower to higher grit, I was shortening the life of the pad, so I bought sanders for each grit from 60 thru 320. That still doesn’t work with random-orbit type sanders. I buy Side A from Superior Pads and Abrasives. I use several of the same grits on the same sander and, after about three Side B’s, the Side A fails to hold Side B any longer. I have a drawer full of Side A backing pads and none of them will hold sandpaper Side B discs. I am using Makita 5-in. random-orbit sanders and a DeWALT 5-in. random-orbit sander.

My questions to you are these: Is there any way to reconstitute Side A Velcro backing pads, or am I just out the money? If there is nothing I can do, is there a manufacturer from whom I can purchase higher quality Side A backing pads? Is there a random-orbit sander I should use instead of Makita or DeWALT? And, can you explain how these backing pads and sanding discs work?” – John App

Chris Marshall: Sorry to hear that you’ve spent so much money on sanders and sanding pads, John! Your problem is perplexing for me because I’ve used many different models of random-orbit sanders with hook-and-loop (Velcro) pads as well as various brands of sanding discs. I’ve never had the same problem with the backing pads eventually failing to hold the discs. Still, I’ll share a couple of thoughts with you here. First, Makita makes quality tools, and so does DeWALT. I don’t think you need to switch sander brands. But, I would advise that if you need to replace their pads, use the exact parts offered by Makita or DeWALT — their pads are designed and tested for the tools. Aftermarket pads may not provide the same interface quality as OEM.

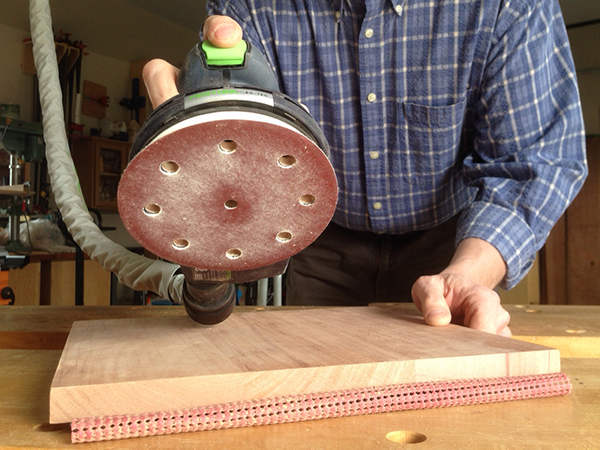

Second, hook-and-loop is a pretty foolproof system: the sander pad’s tiny plastic “hooks” engage with the sanding disc fabric “loops” to hold the discs in place. There’s lots of surface area here, so a very uniform field of connection between hooks and loops. However, it’s possible that one or the other side of the “fit” is contaminated with accumulated sanding dust, and that’s what’s led to a failure. Try vacuuming the pads and discs thoroughly, or clean them with a plastic-bristle brush, and see if that doesn’t improve their attachment to one another. If you don’t connect your sanders to a shop vac or dust extractor during use, that might also help keep sanding dust from eventually clogging the pads.

Another possibility is that when you sand, you’re pressing down so hard on the sander that the heat buildup on the pad’s surface is fracturing and/or overheating the tiny hooks so that they’re deforming or breaking off. Fewer hooks, less “stick.” A random-orbit sander really doesn’t need more downward pressure applied to it than the weight of the tool and your hand. Pushing down doesn’t improve sanding quality, even though it might seem like it speeds up the process. The contrary is usually true: a heavy hand leaves sanding swirls and “pigtail” marks in the wood that can show up under finish, especially when it’s stained — not good. You might extend the life of your sanding pads and actually improve your surface prep efforts by using a gentler hand on the tool and letting the sander’s own weight and motion do most of the work.

Tim Inman: My answer will not be pleasing to you. I have never found the “Velcro” system useful; I use sticky discs. Why? The idea that different grit discs can be peeled off and re-used may seem attractive. In practice, the discs, once used, should be thrown away. To me, working in the shop to make a living, it is folly to try keeping used sanding discs around for a second go later on. Sandpaper, like virtually all other cutting tools in the shop, gets dull. As it wears, the sharp edges of the abrasive material dulls down. Some abrasive grits are said to shear off and renew the cutting edge. But really, for the price of a sticky, I pitch ’em and go for a new sharp one.

The soft interlayer of the attachment system on hook-and-loops also makes sanding and re-shaping with any kind of finesse pretty difficult. Trying to cut a fill to leave a high sharp arise is much easier with a sticky on a firm backer. Sanding a filler flat is easier with stickies, too. That said, I do use hook-and-loop systems on my polishing machines and that works out well.